Method for producing insect tea

A production method and technology for insect tea, which are applied in the field of insect tea production, can solve the problems of easy loss of active ingredients of raw materials, easy breeding of bacteria, etc., so as to improve symptoms of maladaptation, enhance immunity, and reduce cholesterol and B-lipoprotein. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

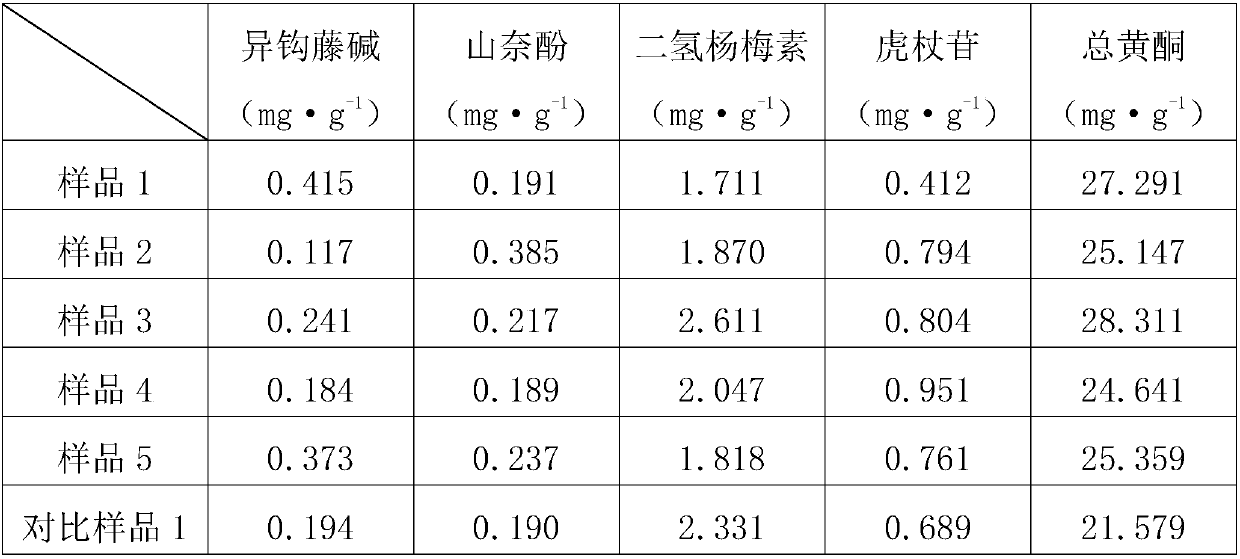

Examples

Embodiment 1

[0042] A method for producing worm tea, comprising the following steps:

[0043] S1. Raw material processing: choose sunny weather, collect plant raw materials, said plant raw materials are selected from Uncaria uncariae, remove dead leaves, diseased parts and foreign matter in plant raw materials, carry out normal temperature drying, dry to water content is 15%, obtain worm tea raw material ;

[0044] S2. Building an insect bed: build a three-dimensional insect bed in a cool, ventilated room. The width of the insect bed is 200 cm, and the length is 300 cm. The three-dimensional construction is 2 layers, and the layer spacing is 100 cm; the bottom layer of the insect bed is made of plastic cloth. The remaining insect beds are made of leaking nets with a pore size of 1 cm, while maintaining the humidity in the room at 80% and the temperature at 32°C;

[0045] S3. Place larvae: Spread the worm tea raw material described in step S1 evenly on the three-dimensional worm bed descri...

Embodiment 2

[0053] A method for producing worm tea, comprising the following steps:

[0054] S1. Raw material processing: choose sunny weather, collect plant raw materials, said plant raw materials are selected from Uncaria uncariae, remove dead leaves, diseased parts and foreign matter in plant raw materials, carry out normal temperature drying, dry to moisture content to 8%, obtain insect tea raw materials ;

[0055] S2. Building an insect bed: build a three-dimensional insect bed in a cool, ventilated room. The width of the insect bed is 50 cm, and the length is 100 cm. There are 5 layers of three-dimensional construction, and the distance between layers is 20 cm; the bottom layer of the insect bed is made of plastic cloth. The remaining insect beds are made of leaking nets with a pore size of 0.5 cm, while maintaining the humidity in the room at 30% and the temperature at 10°C;

[0056] S3. Place larvae: Spread the worm tea raw material described in step S1 evenly on the three-dimens...

Embodiment 3

[0064] A method for producing worm tea, comprising the following steps:

[0065] S1. Raw material processing: choose sunny weather, collect plant raw materials, said plant raw materials are selected from Uncaria uncaria, remove dead leaves, diseased parts and foreign matter in plant raw materials, carry out normal temperature drying, dry to moisture content to 12%, obtain insect tea raw materials ;

[0066] S2. Building an insect bed: build a three-dimensional insect bed in a cool and ventilated room, the width of the insect bed is 125 cm, the length is 200 cm, three layers are built three-dimensionally, and the layer spacing is 60 cm; the bottom layer of the insect bed is made of plastic cloth The remaining insect beds are made of leaking nets with a pore size of 0.75 cm, while maintaining the humidity in the room at 55% and the temperature at 21°C;

[0067] S3. Place larvae: Spread the worm tea raw material described in step S1 evenly on the three-dimensional worm bed descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com