Conductive pearlescent pigment with high refractive index and preparation method thereof

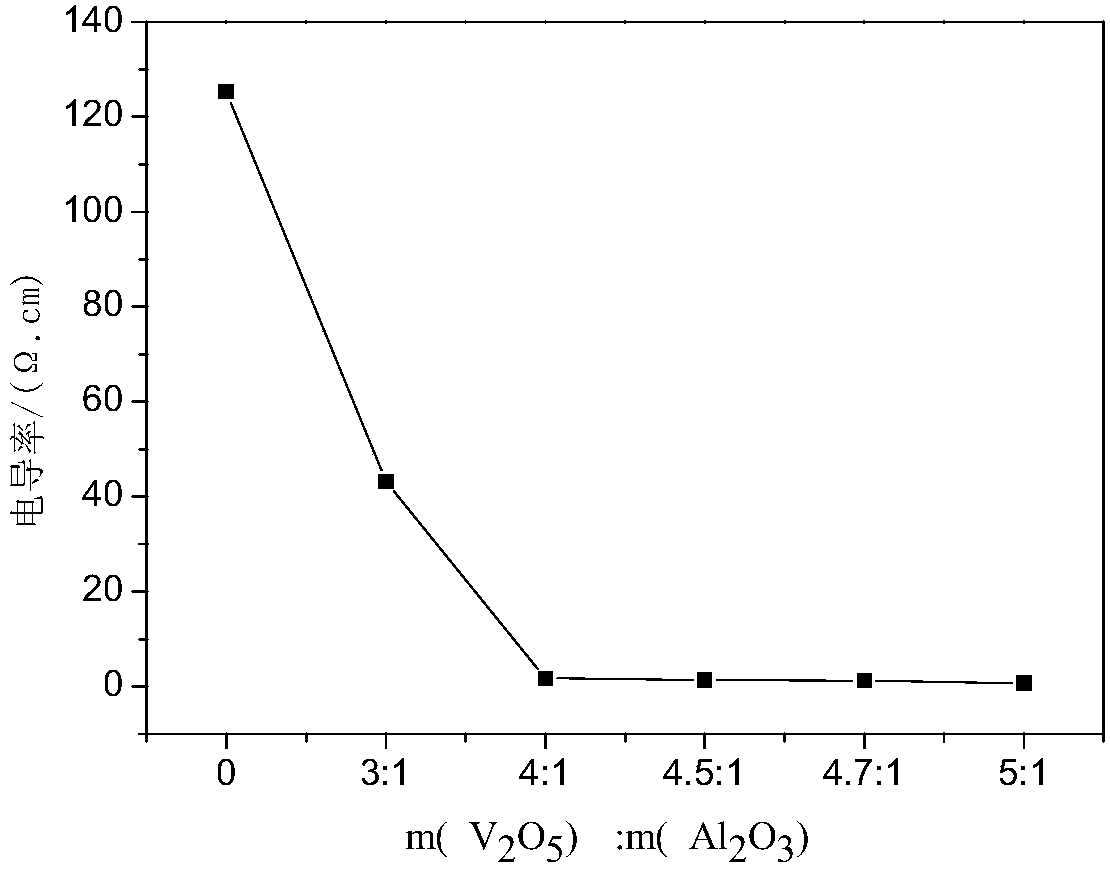

A technology of pearlescent pigments and high refractive index, which is applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., which can solve the problems of pigment luster decline, achieve good electrical conductivity and improve brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Take 10g of bismuth oxychloride pearlescent pigment with a particle size of 12 μm and add 200ml of deionized water into a 1000ml four-neck round bottom flask, start stirring and heating to obtain pearlescent powder slurry, adjust the pH value with 2mol / L sodium hydroxide solution Adjust to 9-9.5, and finally control the reaction temperature to 70°C;

[0025] (2) Take 49ml of 50g / L sodium metavanadate solution and 70.5ml of 20g / L sodium metaaluminate solution, and then add 16.03ml of hydrochloric acid with a concentration of 2mol / L to the above-mentioned pearl powder at a uniform speed while stirring In the slurry, the reaction temperature and pH should be kept constant during this process, and the stirring should be continued for 1 hour after the dropwise addition to obtain the precipitated precursor;

[0026] (3) Cool the obtained precipitation precursor to room temperature, then wash it with deionized water to neutrality, dry it, and finally calcinate it at 500°C ...

Embodiment 2

[0029] (1) Get 10g of bismuth oxychloride pearlescent pigment with a particle size of 12 μm and 200ml of deionized water into a 1000ml four-necked round-bottomed flask, start stirring and heating to obtain pearlescent powder slurry, and adjust the pH with 2mol / L sodium hydroxide solution Adjust the value to 9-9.5, and finally control the reaction temperature to 70°C;

[0030] (2) Take 72.3ml of 50g / L sodium metavanadate solution, 78.7ml of 20g / L sodium metaaluminate solution, and 21.49ml of hydrochloric acid with a concentration of 2mol / L, and add them dropwise to the above pearl powder at a uniform speed while stirring In the slurry, the reaction temperature and pH should be kept constant during this process, and the stirring should be continued for 30 minutes after the dropwise addition to obtain the precipitated precursor;

[0031] (3) Cool the obtained precipitation precursor to room temperature, then wash it with deionized water to neutrality, dry it, and finally calcinat...

Embodiment 3

[0034] (1) Take 10g of bismuth oxychloride pearlescent pigment with a particle size of 12 μm and add 200ml of deionized water into a 1000ml four-neck round bottom flask, start stirring and heating to obtain pearlescent powder slurry, adjust the pH value with 2mol / L sodium hydroxide solution Adjust to 9-9.5, and finally control the reaction temperature to 80°C;

[0035] (2) Take 84.4ml of 50g / L sodium metavanadate solution and 81ml of 20g / L sodium metaaluminate solution, and then add 24.17ml of hydrochloric acid with a concentration of 2mol / L to the above pearl powder at a uniform speed while stirring In the slurry, the reaction temperature and pH should be kept constant during this process, and the stirring should be continued for 2 hours after the dropwise addition to obtain the precipitated precursor;

[0036] (3) Cool the obtained precipitation precursor to room temperature, then wash it with deionized water to neutrality, dry it, and finally calcinate it at 500°C for 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com