Rubber-plastic composite lock-catch rubber floor and production method thereof

A technology of rubber flooring and manufacturing methods, which is applied in the direction of elastic flooring, rubber layered products, chemical instruments and methods, etc., can solve the problems of high requirements for floor installation and laying, poor wear resistance of PVC flooring, and influence on market development prospects, etc., and achieve the goal of using Long life, easy installation, good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment discloses a rubber-plastic composite locking rubber floor, which includes a surface layer and a bottom layer, wherein the surface layer and the bottom layer are pressed together by environmentally friendly glue, and the bottom layer is locked by slotting;

[0024] Wherein, the surface layer is vulcanized rubber, which is composed of the following parts by mass: styrene-butadiene rubber 50-80, natural rubber 10-30, nitrile rubber 0-30, zinc oxide 4-8, stearic acid 4-10, promoting Agent 3-6, anti-aging agent 2-4, white carbon black 20-40, kaolin 30-50, flame retardant 50-80, sulfur 2-5, pigment 2-10, accelerators are thiurams and thiazoles , the flame retardant is an inorganic flame retardant, and the anti-aging agent is a phenolic anti-aging agent; the bottom layer is a plastic hard micro-foaming layer, and the bottom layer includes but is not limited to polyvinyl chloride, polypropylene, polystyrene and other foaming materials ; The environmentally frien...

Embodiment 2

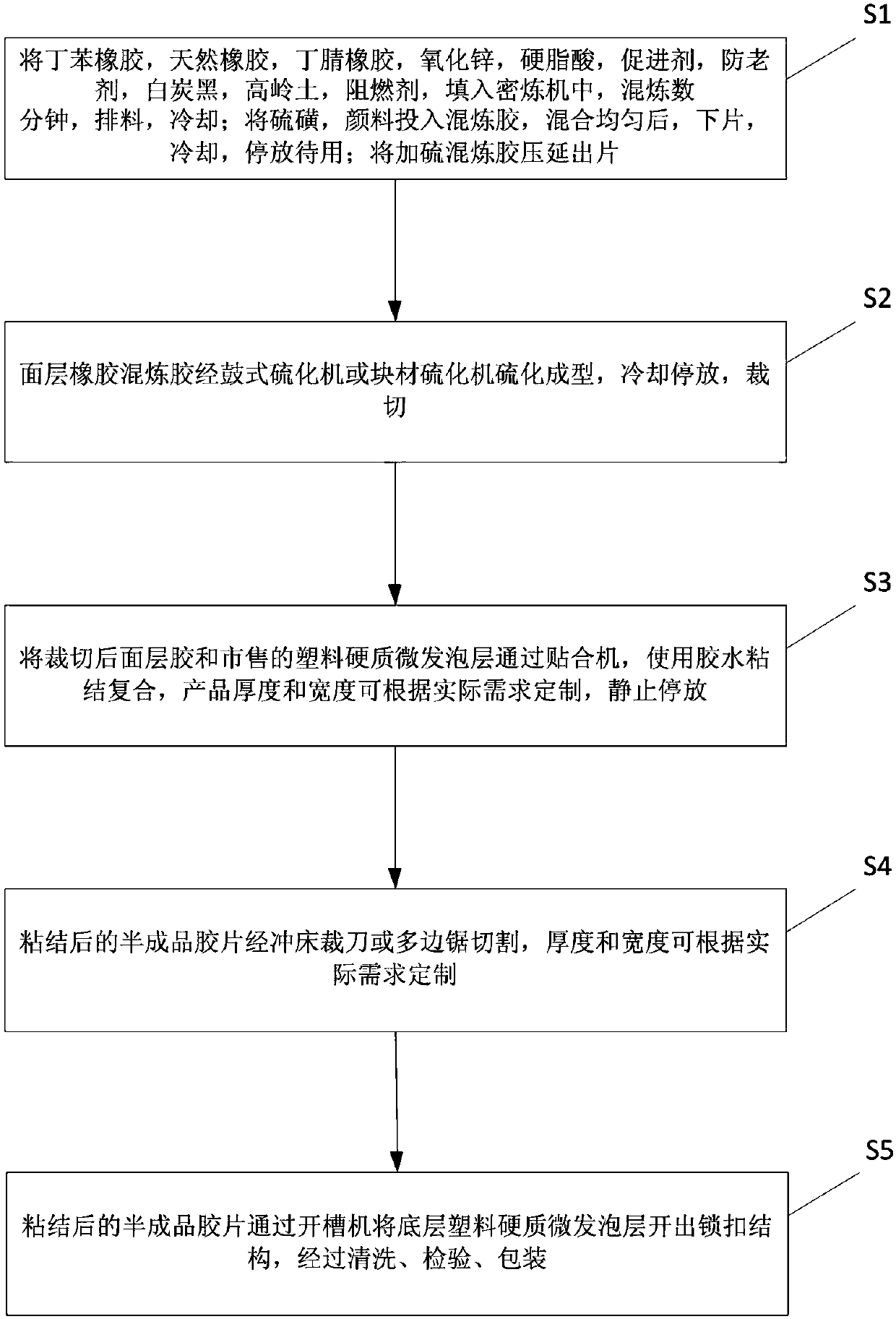

[0029] This embodiment discloses a method for manufacturing a rubber-plastic composite locking rubber floor, and the method includes the following steps:

[0030] The first step is to mix styrene-butadiene rubber 50-80, natural rubber 10-30, nitrile rubber 10-30, zinc oxide 4-8, stearic acid 4-10, accelerator 3-6, anti-aging agent 2-4, white Carbon black 20-40, kaolin 30-50, flame retardant 50-80, fill in the internal mixer, knead for 5-20 minutes, discharge, cool; put sulfur 2-5, pigment 2-10 into kneading After the rubber is mixed evenly, it is released, cooled, and parked for use; the vulcanized mixed rubber is rolled out, and the thickness and width can be customized according to actual needs. The thickness can reach 0.5-3.0mm, and the width can reach 0.5-2.0m. Length 90-100m;

[0031] The second step is to vulcanize the surface layer rubber compound through a drum vulcanizer or block vulcanizer, cool and park, and cut to a length of 0.5-2.0m;

[0032] The third step is ...

Embodiment 3

[0036] This embodiment discloses a method for manufacturing a rubber-plastic composite locking rubber floor, and the method includes the following steps:

[0037] In the first step, 48kg of styrene-butadiene rubber, 12kg of natural rubber, 3kg of zinc oxide, 3kg of stearic acid, 0.6kg of accelerator A, 1.2kg of accelerator B, 1.2kg of anti-aging agent, 18kg of white carbon black, 30kg of kaolin, aluminum hydroxide 36kg, filled into the internal mixer, mixed for 15 minutes, discharged, and cooled; put 2.4kg of sulfur and 3.6kg of pigment into the rubber compound, after mixing evenly, the tablet was removed, cooled, and parked for use; mixed with sulfur Rubber calendered sheet, thickness and width can be customized according to actual needs, thickness 1.5mm, width 1.0m, length 100m;

[0038] In the second step, the surface layer rubber compound is vulcanized by a drum vulcanizer, cooled and parked, and cut into lengths of 1.0m;

[0039] The third step is to pass the glue of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com