Auger bit with abrasion resistance and toughness and preparing method thereof

A technology of wear resistance and toughness, applied in the field of rotary digging teeth and its preparation, can solve the problems of easy brittle fracture of rotary digging teeth, lower toughness of substrate, easy peeling of cladding layer, etc., to maintain overall toughness and simple operation , to ensure the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

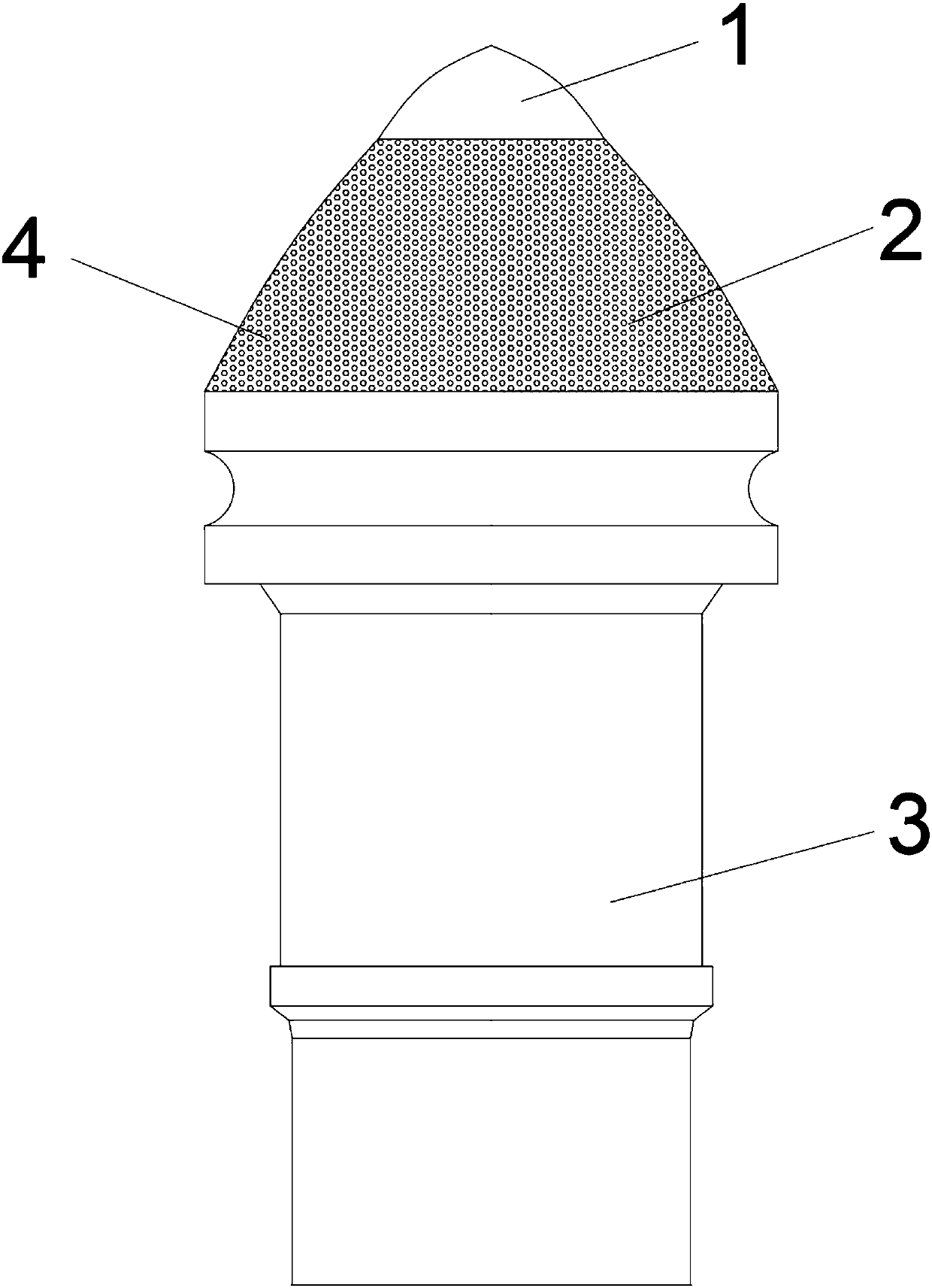

[0029] A rotary digging tooth with both wear resistance and toughness, such as figure 1 As shown, from top to bottom, it includes wear head 1, tooth body 2 and tooth shank 3. The tooth body 2 and tooth shank 3 are integrally formed, and the material is H13K (4Cr5MoSiV1). The lower end of the wear head 1 is embedded in the tooth body 2. In the wear-resistant head groove 21 at the top, the surface of the tooth body 2 is provided with dot-shaped dispersive alloy strengthened micro-regions 4, and the alloy strengthened micro-regions 4 are formed by the pulse laser melting the tooth body substrate during the subsequent rapid cooling and solidification process. It is formed by the WC reinforcement phase particles wrapped in the micro-melt pool, and the diameter of a single alloy-reinforced micro-region 4 is 1000 μm.

[0030] The rotary digging tooth with both wear resistance and toughness of this embodiment is made by the following process:

[0031] (1) Raw material (material is H13K (4...

Embodiment 2

[0046] A rotary digging tooth with both abrasion resistance and toughness is basically the same as Example 1, except that the integrally formed tooth body and tooth shank are made of 42CrMo, and the surface of the tooth body is provided with a rotary digging tooth. A spiral-shaped alloy strengthened micro-area in the height direction. The spiral-shaped micro-melt pool formed by continuous laser melting of the tooth base material wraps the WC-reinforced phase in the spiral micro-melt pool during the subsequent rapid cooling and solidification process The melting width of the spiral alloy strengthened micro-regions formed by the particles is 3mm.

[0047] The preparation method of the rotary digging tooth with both wear resistance and toughness of this embodiment is basically the same as that of embodiment 1, and the only difference is:

[0048] In step (5), the overall quenching temperature is 1000°C, the low temperature tempering temperature of the tooth handle is 250°C, and the hi...

Embodiment 3

[0051] A rotary digging tooth with both wear resistance and toughness, which is basically the same as Example 1, except that: the integrally formed tooth body and tooth shank are made of 25Cr2Mo1V, and the surface of the tooth body is provided with dot-shaped dispersion alloy strengthening micro-regions And the alloy-strengthened micro-regions spirally shaped along the height of the rotary digging tooth body. The point-shaped dispersive alloy strengthened micro-area is formed by the micro-melt pool formed by the pulse laser melting the tooth base material in the subsequent rapid cooling and solidification process, and the WC reinforcement phase particles in the micro-melt pool are wrapped. The diameter is 1000 μm. The spiral alloy strengthened micro-area is formed by the spiral micro-melt pool formed by continuous laser melting of the tooth base material, which is formed by wrapping the WC reinforcing phase particles in the spiral micro-melt pool during the subsequent rapid coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com