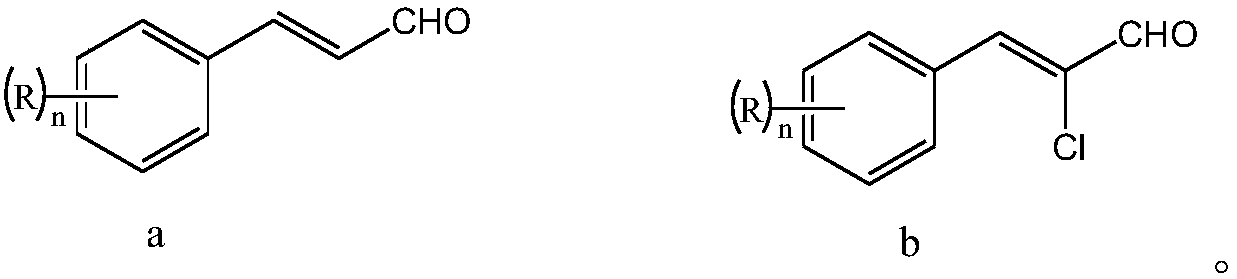

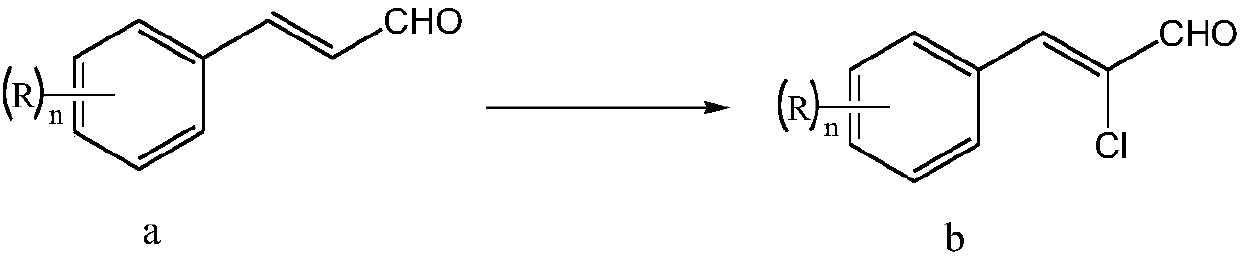

Method for synthesizing alpha-chloro-cinnamyl aldehyde compound

A compound, the technology of chlorinated meat, which is applied in the field of preparation of α-chlorocinnamaldehyde compounds, can solve the problems of complex catalysts, difficult synthesis, expensive starting materials, etc., and achieve high yield, simple operation, common substrates adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

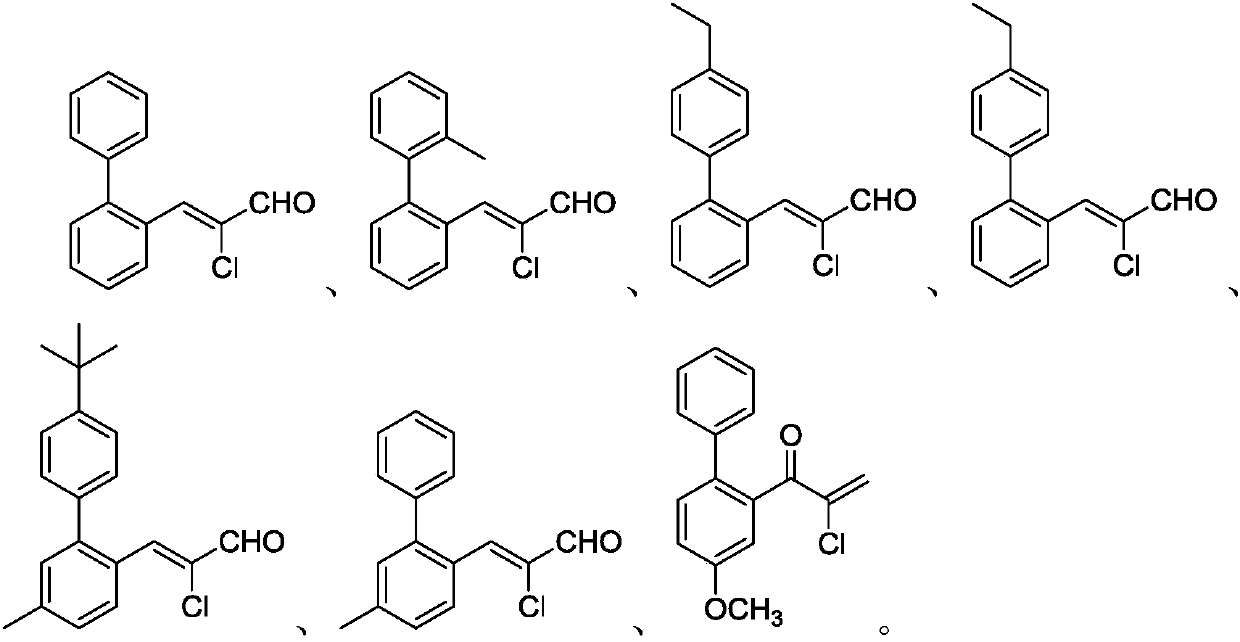

Examples

Embodiment 1

[0024]

[0025] Add 0.3mmol of o-phenylcinnamaldehyde and 0.45mmol of ferric chloride into a 15mL pressure-resistant tube, and then add 3mL of acetonitrile / water (V:V=100:1) as a solvent. Next, magnetically stir at 140° C. for 12 h. Then, two spoonfuls of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the solvent was removed by distillation under reduced pressure, and the pure product was obtained by column chromatography separation (with petroleum ether / ethyl acetate=40:1 as an eluent). The substance was a yellow solid, the chemical name was o-phenyl-α-chlorocinnamaldehyde, and the yield was 69%.

[0026] Characterization data: 1 H NMR (CDCl 3 ,500MHz):9.35(s,1H),8.26(d,J=8.0Hz,1H),7.56-7.43(m,7H),7.34-7.33(m,2H); 13 C NMR (CDCl 3 ,125MHz): δ186.5, 145.4, 143.7, 139.6, 132.9, 130.8, 130.3, 130.3, 130.2, 129.8, 129.7, 128.1, 127.3.

Embodiment 2

[0028]

[0029] Add 0.3mmol of o-phenylcinnamaldehyde and 0.9mmol of copper chloride into a 15mL pressure-resistant tube, and then add 3mL of dimethyl sulfoxide as a solvent. Then, magnetic stirring was performed at 150° C. for 8 h. Then, two spoonfuls of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the solvent was removed by distillation under reduced pressure, and the pure product was obtained by column chromatography separation (with petroleum ether / ethyl acetate=40:1 as an eluent). The substance was a yellow solid, the chemical name was o-phenyl-α-chlorocinnamaldehyde, and the yield was 61%.

[0030] Characterization data: 1 H NMR (CDCl 3 ,500MHz):9.35(s,1H),8.26(d,J=8.0Hz,1H),7.56-7.43(m,7H),7.34-7.33(m,2H); 13 C NMR (CDCl 3 ,125MHz): δ186.5, 145.4, 143.7, 139.6, 132.9, 130.8, 130.3, 130.3, 130.2, 129.8, 129.7, 128.1, 127.3.

Embodiment 3

[0032]

[0033] Add 0.3 mmol of o-phenylcinnamaldehyde and 0.3 mmol of cuprous chloride into a 15 mL pressure-resistant tube, and then add 3 mL of acetonitrile / water (V:V=400:1) as a solvent. Then, magnetically stir at 90° C. for 24 h. Then, two spoonfuls of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the solvent was removed by distillation under reduced pressure, and the pure product was obtained by column chromatography separation (with petroleum ether / ethyl acetate=40:1 as an eluent). The substance was a yellow solid, the chemical name was o-phenyl-α-chlorocinnamaldehyde, and the yield was 44%.

[0034] Characterization data: 1 H NMR (CDCl 3 ,500MHz):9.35(s,1H),8.26(d,J=8.0Hz,1H),7.56-7.43(m,7H),7.34-7.33(m,2H); 13 C NMR (CDCl 3 ,125MHz): δ186.5, 145.4, 143.7, 139.6, 132.9, 130.8, 130.3, 130.3, 130.2, 129.8, 129.7, 128.1, 127.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com