TC4 titanium alloy and preparation method thereof

A technology of titanium alloy and titanium dioxide, which is applied in the field of TC4 titanium alloy and its preparation, can solve the problems of high smelting environment and equipment requirements, high production cost, long process flow, etc., and achieves favorable separation, low production cost and low raw material price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

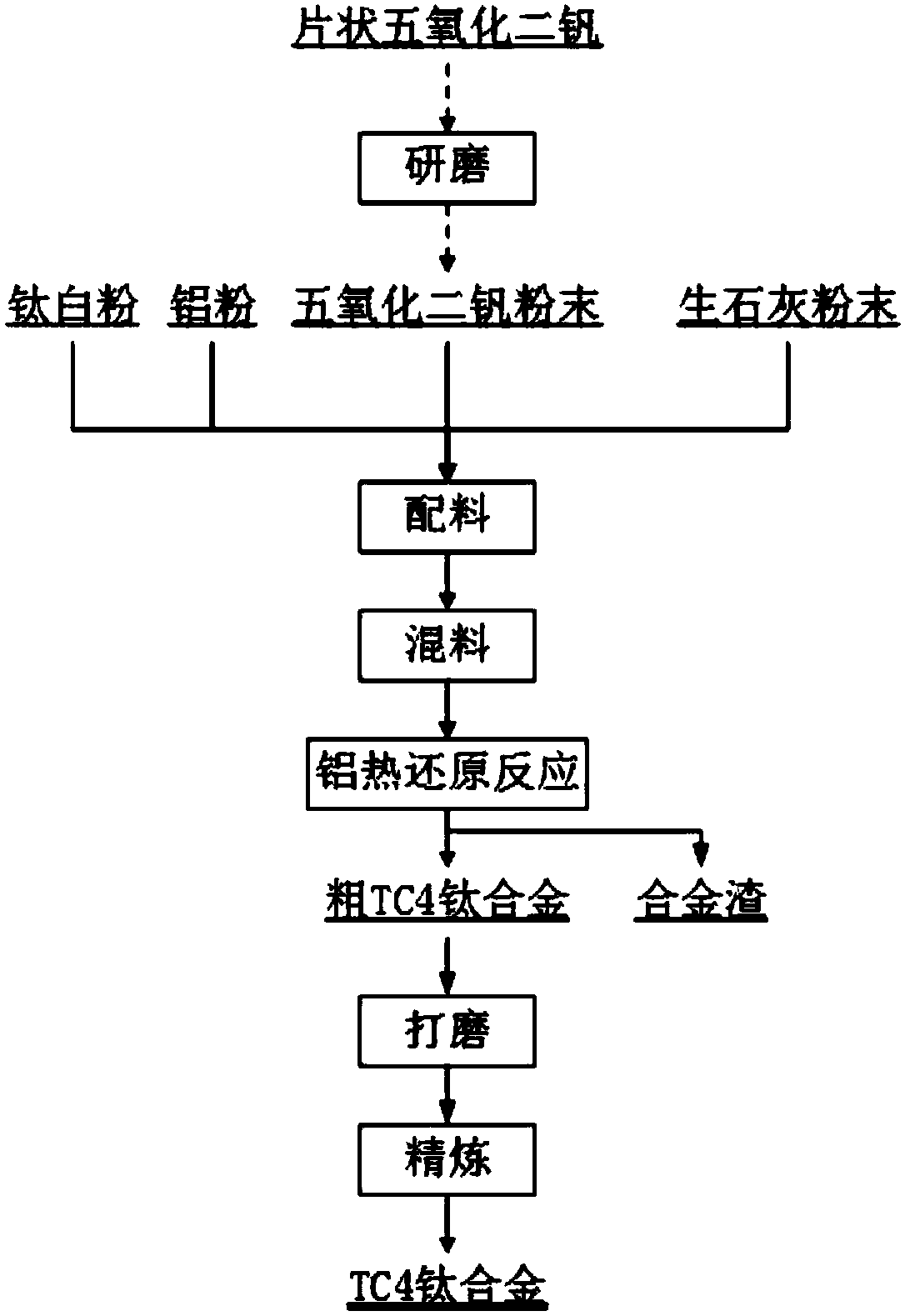

[0027] A preparation method of TC4 titanium alloy, comprising the following steps:

[0028] (1) Grinding 10min with the sample preparation machine of flake vanadium pentoxide, taking by weighing vanadium pentoxide powder 3g (1.5wt%), titanium dioxide 90g (45wt%), aluminum powder 36g (18wt%) and unslaked lime powder 71g ( 35.5wt%) is placed in a ball mill jar, and taken out after ball milling by a ball mill for 1 h;

[0029] Among them, the purity of vanadium pentoxide is ≥99%, and TiO in titanium dioxide 2 The content of Al ≥ 98%, the content of Al in aluminum powder ≥ 99%, the content of CaO in quicklime ≥ 98%;

[0030] Vanadium pentoxide particle size ≤0.10mm, titanium dioxide particle size ≤0.075mm, aluminum powder particle size ≤0.10mm, quicklime particle size ≤0.10mm;

[0031] (2) Place the product obtained in step (1) in a corundum crucible, put the corundum crucible into a heated muffle furnace at a temperature of 1450°C, keep it warm for 30 minutes, then take out the...

Embodiment 2

[0035] A preparation method of TC4 titanium alloy, comprising the following steps:

[0036] (1) Grind flake vanadium pentoxide with a sample maker for 10min, weigh 4g (2wt%) of vanadium pentoxide powder, 80g (40wt%) of titanium dioxide, 42g (21wt%) of aluminum powder and 74g (37wt%) of quicklime powder %) is placed in a ball mill jar, and taken out after ball milling by a ball mill for 0.5h;

[0037] Among them, the purity of vanadium pentoxide is ≥99%, and TiO in titanium dioxide 2 The content of Al ≥ 98%, the content of Al in aluminum powder ≥ 99%, the content of CaO in quicklime ≥ 98%;

[0038] Vanadium pentoxide particle size ≤0.10mm, titanium dioxide particle size ≤0.075mm, aluminum powder particle size ≤0.10mm, quicklime particle size ≤0.10mm;

[0039](2) Put the product obtained in step (1) in a corundum crucible, put the corundum crucible into a heated muffle furnace at a temperature of 1550°C, keep it warm for 15 minutes, then take out the crucible and air-cool it t...

Embodiment 3

[0043] A preparation method of TC4 titanium alloy, comprising the following steps:

[0044] (1) Weigh 4g (2wt%) of vanadium pentoxide powder, 84g (42wt%) of titanium dioxide, 40g (20wt%) of aluminum powder and 76g (36wt%) of quicklime powder and place them in a ball mill jar, and use a ball mill to grind for 1h take out;

[0045] Among them, the purity of vanadium pentoxide is ≥99%, and TiO in titanium dioxide 2 The content of Al ≥ 98%, the content of Al in aluminum powder ≥ 99%, the content of CaO in quicklime ≥ 98%;

[0046] Vanadium pentoxide particle size ≤0.10mm, titanium dioxide particle size ≤0.075mm, aluminum powder particle size ≤0.10mm, quicklime particle size ≤0.10mm;

[0047] (2) Put the product obtained in step (1) in a corundum crucible, put the corundum crucible into a heated muffle furnace at a temperature of 1650°C, keep it warm for 20 minutes, then take out the crucible and air-cool it to room temperature to obtain TC4 titanium alloy and aluminum Thermal r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com