Lithium-pre-embedded hard carbon material, and preparation method and application thereof

A technology of pre-embedding lithium and hard carbon, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problem of lower volume specific energy of capacitors, and achieve constant volume specific energy, short time consumption and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

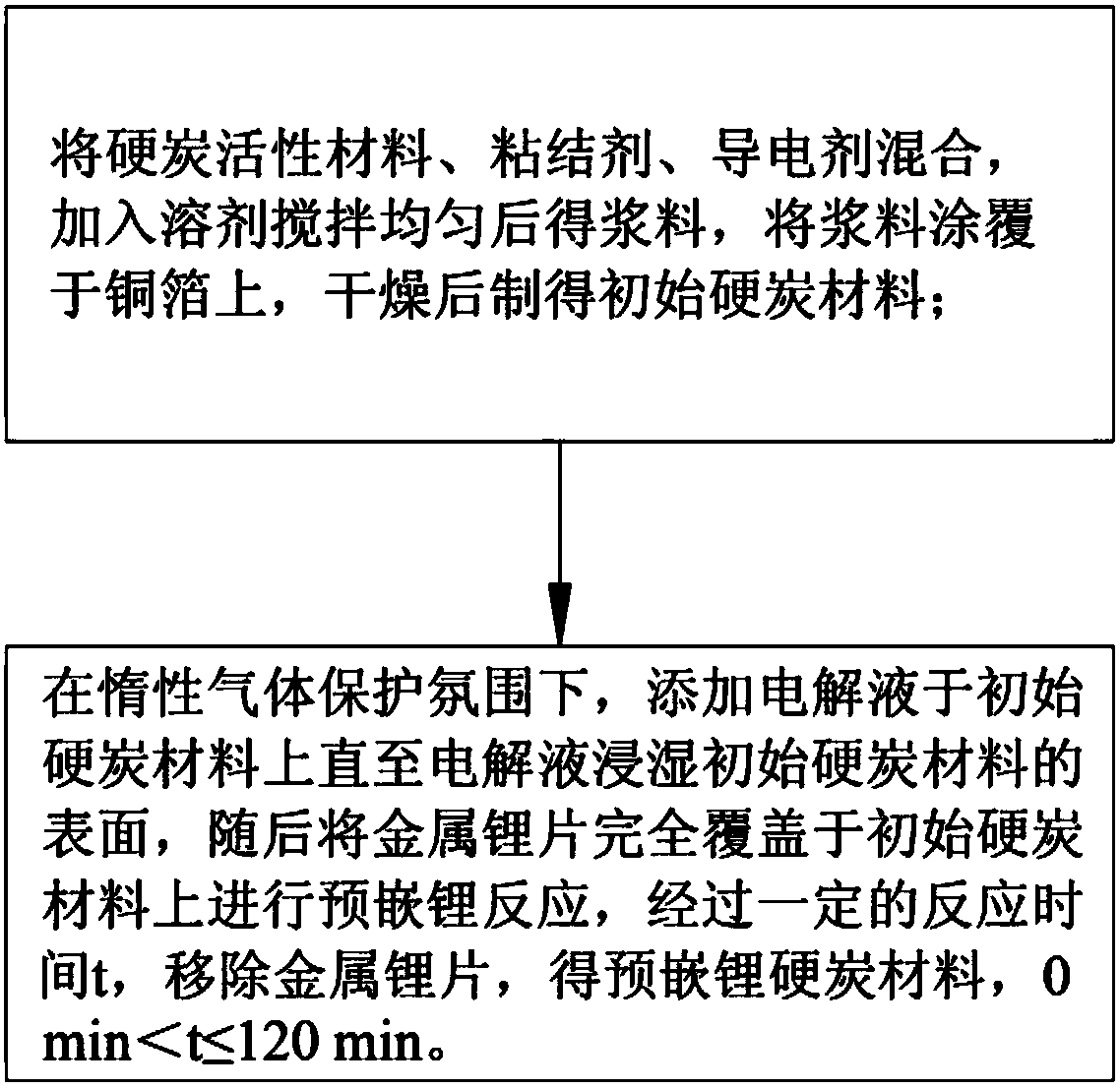

[0032] A preparation method for pre-intercalated lithium hard carbon material, comprising the following steps:

[0033] S1. Mix the hard carbon active material, binder, and conductive agent, add a solvent and stir evenly to obtain a slurry, coat the slurry on a copper foil, and dry to obtain an initial hard carbon material;

[0034] S2. Under the protective atmosphere of inert gas, add electrolyte on the initial hard carbon material until the electrolyte wets the surface of the initial hard carbon material, and then completely cover the metal lithium sheet on the initial hard carbon material for pre-intercalation lithium reaction, after After a certain reaction time t, the metal lithium sheet is removed to obtain a pre-intercalated lithium hard carbon material, 0min<t≤120min.

Embodiment 1

[0036] Such as figure 1 As shown, the preparation method of a kind of pre-intercalated lithium hard carbon material of the present embodiment comprises the following steps:

[0037] S1. Preparation of initial hard carbon materials

[0038] Mix the hard carbon / graphene composite material as the active material, polyvinylidene fluoride (PVDF) as the binder, and acetylene black as the conductive agent in a mass ratio of 8:1:1, add N-methylpyrrolidone as the solvent, and stir evenly After the slurry is obtained, the slurry is coated on a copper foil with a thickness of 10 μm, and after drying, it is punched into a disc with a diameter of 12 mm, and the disc is placed in an oven at 110 ° C for 6 hours to obtain the initial hard carbon material;

[0039] In this embodiment, the hard carbon / graphene composite material is prepared by the following steps:

[0040] S1-1. Add 0.4g of graphene oxide and 2g of hard carbon prepared by the Hummers method to an aqueous solution of 100mL of ...

Embodiment 2

[0052] The preparation method of the pre-embedded lithium hard carbon material in this example is the same as that in Example 1, the difference is that:

[0053] The pre-intercalation lithium reaction time t in the step S2 is 30 min.

[0054] figure 2 Be the SEM figure of initial hard carbon material in the present embodiment, image 3 This is the SEM image of the pre-intercalated lithium hard carbon material in this example, which shows that an obvious porous solid electrolyte interface (SEI) film has been formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com