Monoatomic dispersed noble metal catalyst and application thereof

A noble metal catalyst, atomic dispersion technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problem of steady-state start-up and use stability, which has not been reported to achieve excellent stability in use, inhibit methanation side reactions, and avoid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

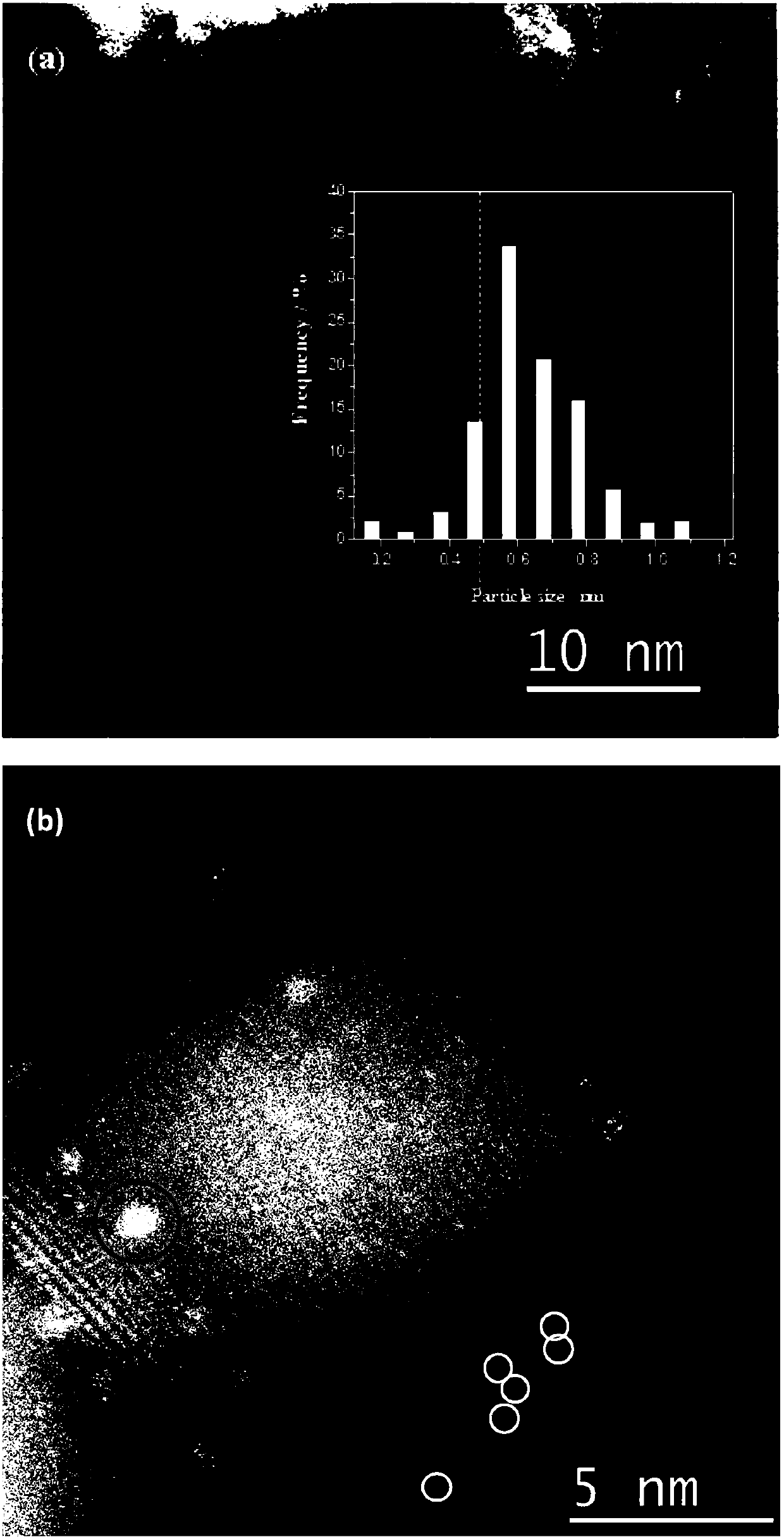

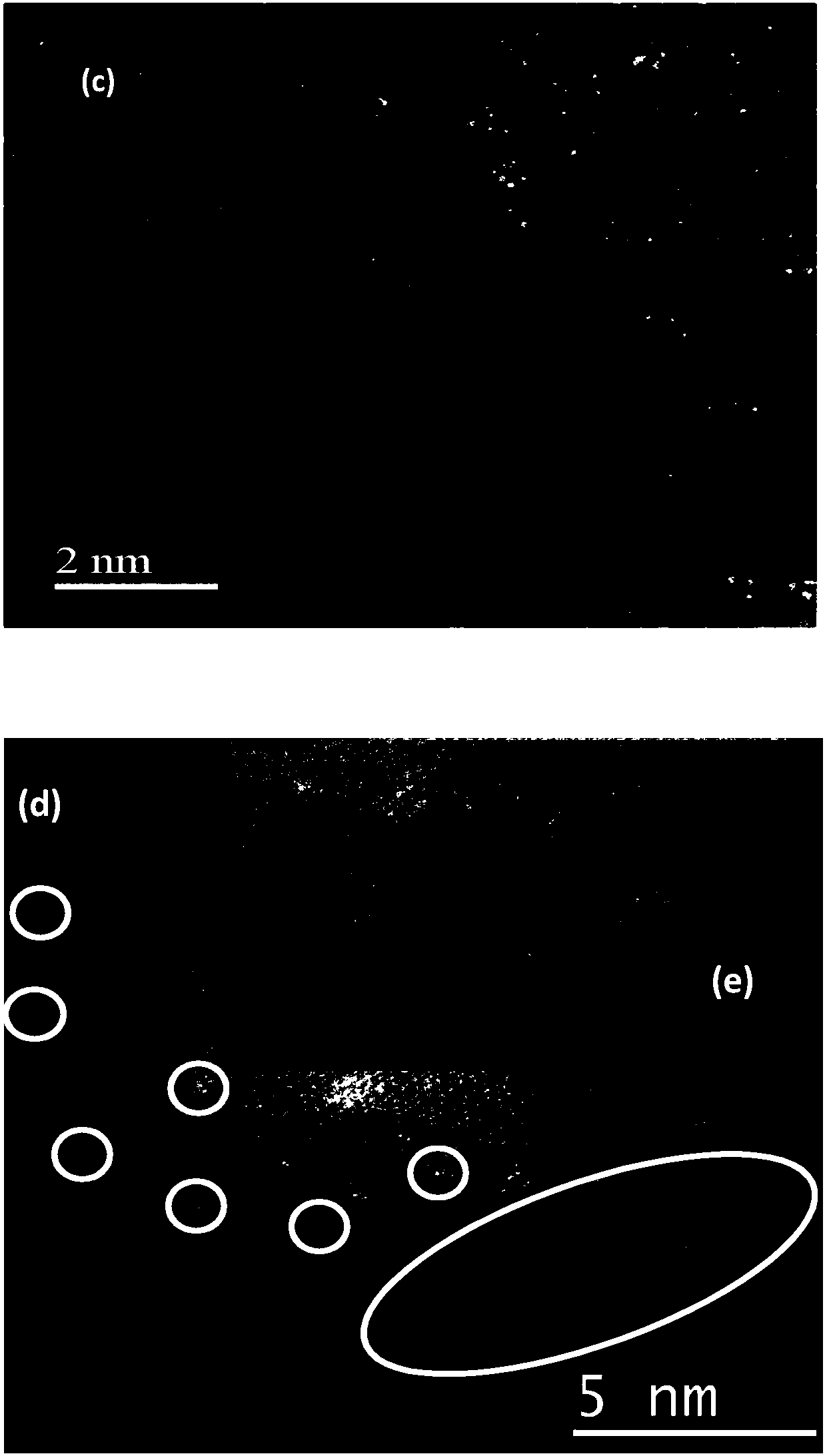

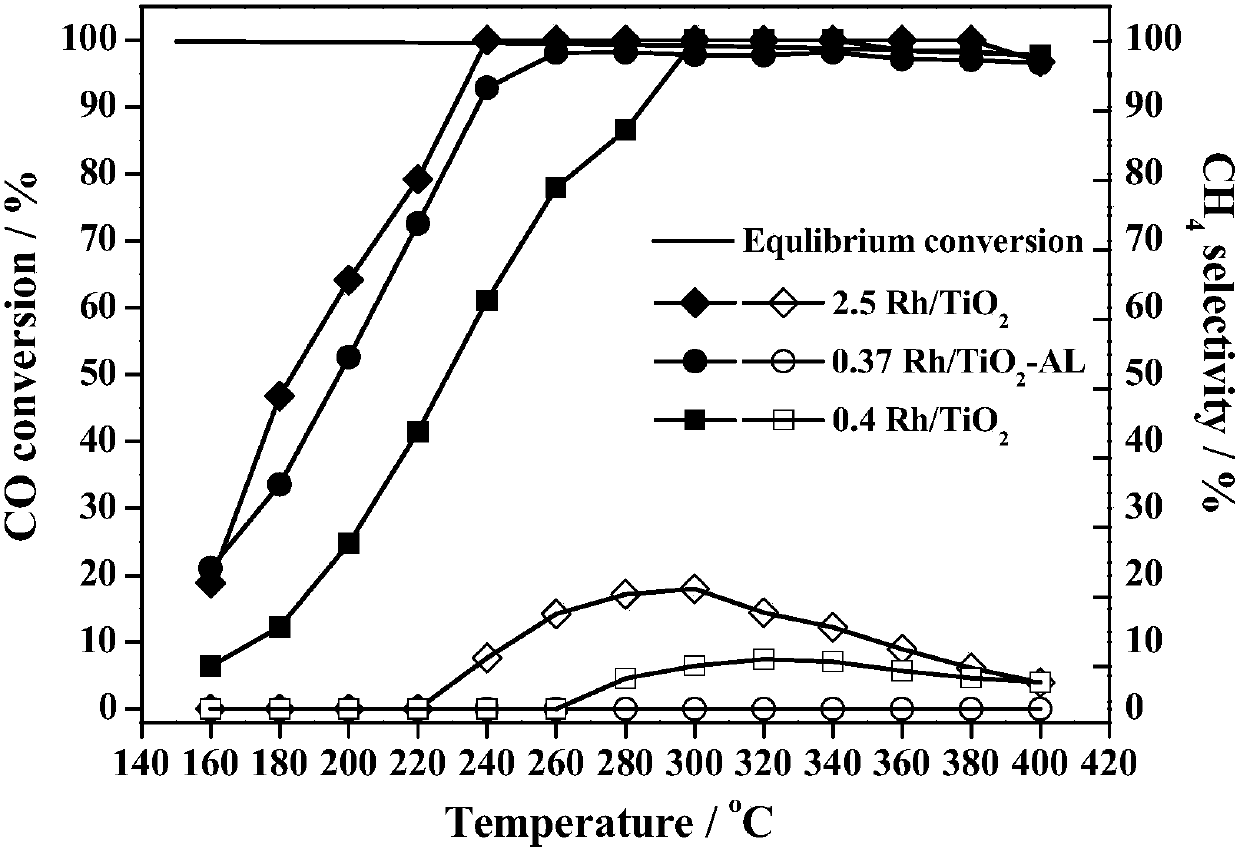

[0033] Ultrasonic disperse 1g of P25 carrier in 100mL deionized water to form a suspension; take 40mL of 0.68mg / mL RhCl 3Solution, add 100mL deionized water to stir and dilute, and add dropwise to the carrier suspension under strong stirring, adjust the pH value to 9.4, stir at 80°C for 3h, let stand for 1h, filter, wash with hot water, and dry in an oven at 80°C 12h. After drying, the catalyst was calcined at 400°C in air for 4h to obtain 2.5wt.%Rh / TiO 2 catalyst.

Embodiment 2

[0035] With 0.3g embodiment 1 described 2.5wt.%Rh / TiO 2 Catalyst at 30mL / min of 10vol.%H 2 / He was reduced at 200°C for 30 min, and quickly transferred to 30 mL of 11.6 mol / L HCl / 1% H under vigorous stirring. 2 o 2 In the mixed solution, stir and react at 65°C for 3h, filter, wash with hot water, and dry in an oven at 80°C for 12h to obtain 0.4wt.%Rh / TiO 2 -AL catalyst.

Embodiment 3

[0037] Prepare 7.9wt.%Rh / TiO by the method described in embodiment 1 2 catalyst. Implement 7.9wt.%Rh / TiO with 0.3g 2 Catalyst at 30mL / min of 10vol.%H 2 / He was reduced at 200°C for 30 min, and quickly transferred to 30 mL of 11.6 mol / L HCl / 1% H under vigorous stirring. 2 o 2 In the mixed solution, stir and react at 65°C for 3h, filter, wash with hot water, and dry in an oven at 80°C for 12h to obtain 2.0wt.%Rh / TiO 2 -AL catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com