Direct-writing forming method of precursor conversion ceramic

A technology of precursor conversion and direct writing molding, applied in ceramic molding machines, ceramic products, applications, etc., can solve the problems of increasing the controllability of finished product performance, high precision, low repetition rate, high cost, etc., and achieve excellent rheology and curing ability, simplified process route, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] Example 1, using polycarbosilane / n-hexane as a slurry to prepare micron-scale three-dimensional structure ceramics

[0055] Mix 5g of polycarbosilane and 20ml of n-hexane, and stir it by magnetic force at room temperature for 2h until the polycarbosilane is fully dissolved in n-hexane. Then, stir at 50° C. to volatilize the organic solvent to obtain a slurry with a solid content of 80 wt%. The slurry was injected into a 50ml syringe, and centrifuged at 1000r / min for 10 minutes to remove the slurry air bubbles.

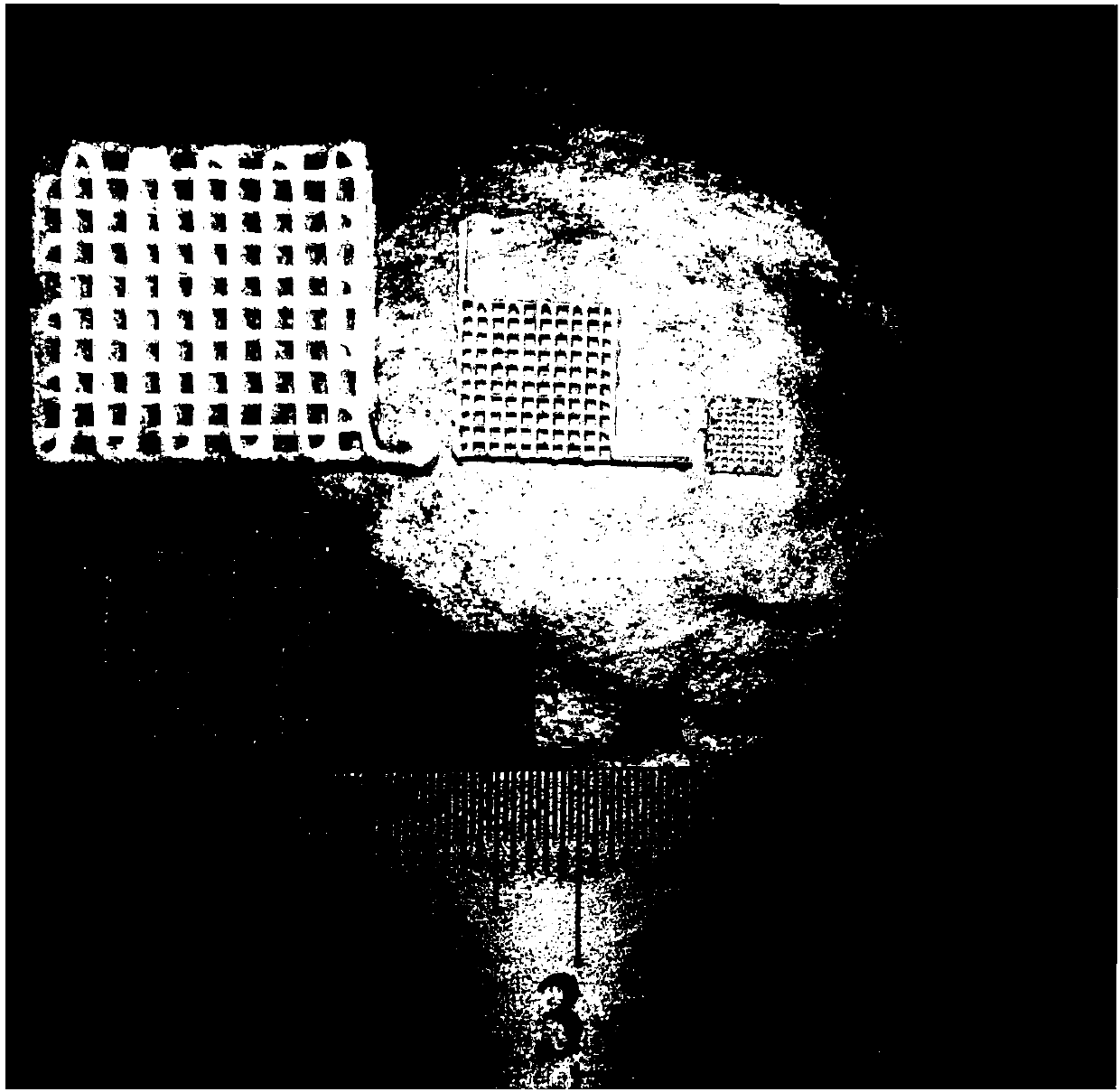

[0056] Then install a 200um aperture needle on the top of the barrel. Perform direct writing molding on the paste, and obtain a criss-cross three-dimensional structure on the glass slide. Molding pressure 20PSI; moving speed 5mm / s.

[0057] After the organic solvent on the green body is completely volatilized, the printed precursor is placed in a blast drying oven for oxidative cross-linking treatment. The temperature setting range is 200°C, and the crosslin...

example 2

[0065] Using polycarbosilane / n-hexane as slurry to prepare micron-scale three-dimensional structure ceramics;

[0066] Mix 5g of polycarbosilane and 20ml of n-hexane, and stir it by magnetic force at room temperature for 2h until the polycarbosilane is fully dissolved in n-hexane. Then, stir at 50° C. to volatilize the organic solvent to obtain a slurry with a solid content of 70 wt%. The slurry was injected into a 50ml syringe, and centrifuged at 1000r / min for 10 minutes to remove the slurry air bubbles.

[0067] Then install a 100um aperture needle on the top of the barrel. Perform direct writing molding on the paste, and obtain a criss-cross three-dimensional structure on the glass slide. Molding pressure 40PSI; moving speed 1mm / s.

[0068]After the organic solvent on the green body is completely volatilized, the printed precursor is placed in a blast drying oven for oxidative cross-linking treatment. The temperature setting range is 200°C, and the crosslinking time is ...

example 3

[0074] Using polycarbosilane / divinylbenzene to prepare micron-scale three-dimensional structure ceramics for the future;

[0075] Mix 5g of polycarbosilane and 8g of divinylbenzene. After the polycarbosilane is completely dissolved in divinylbenzene, put it into a test tube, seal it, put it in an oven, stir at 150°C for 4 hours, and then put it in a test tube at 50°C. Stir to volatilize the crosslinking agent to obtain a slurry with a solid content of 80 wt%. The slurry was injected into a 50ml syringe, and centrifuged at 2000r / min for 10 minutes to remove the slurry bubbles.

[0076] Then install a 400um aperture needle on the top of the barrel. Perform direct writing molding on the paste, and obtain a criss-cross three-dimensional structure on the glass slide. Molding pressure 50PSI; moving speed 5mm / s.

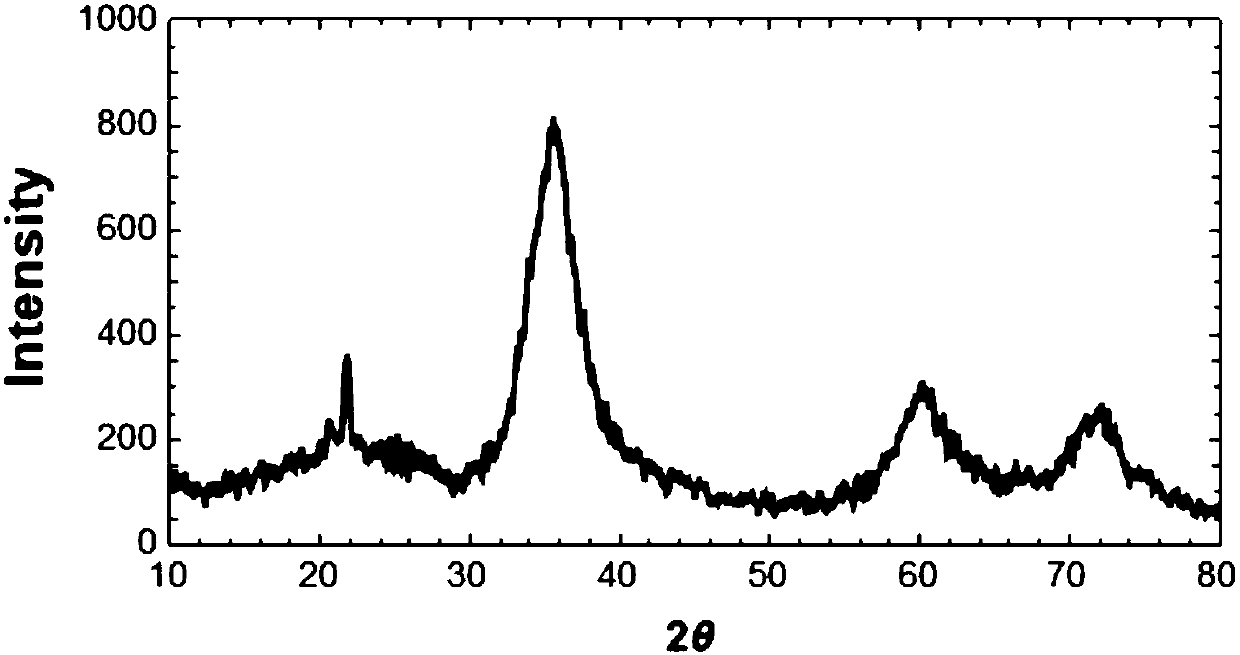

[0077] After the organic solvent on the green body was completely volatilized, the printed precursor was placed in a tube furnace, and in a nitrogen atmosphere, the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average compressive strength | aaaaa | aaaaa |

| Average compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com