Preparation method of isobutylene superposition reaction

A superposition reaction and preparation process technology, applied in the field of petrochemical industry, can solve the problems of complex reaction and low conversion rate of isobutene, achieve the effect of simplifying the separation process, improving the conversion rate and selectivity, and compensating for the loss of gasoline production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

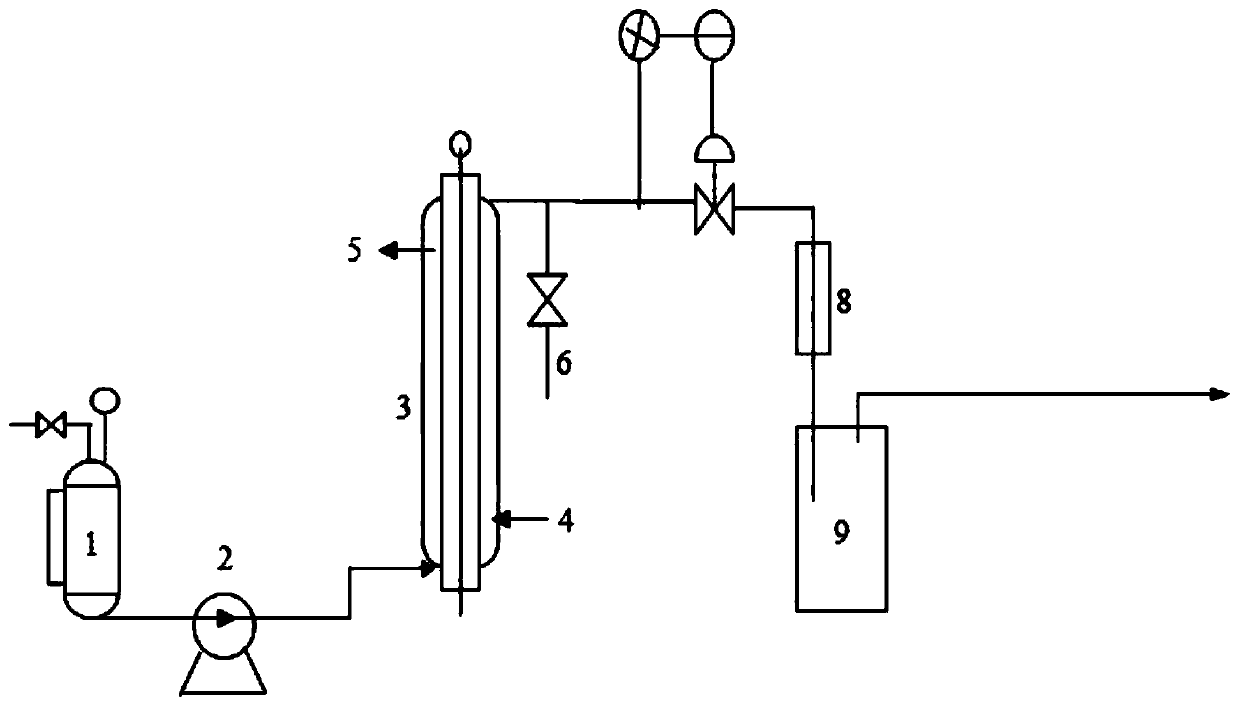

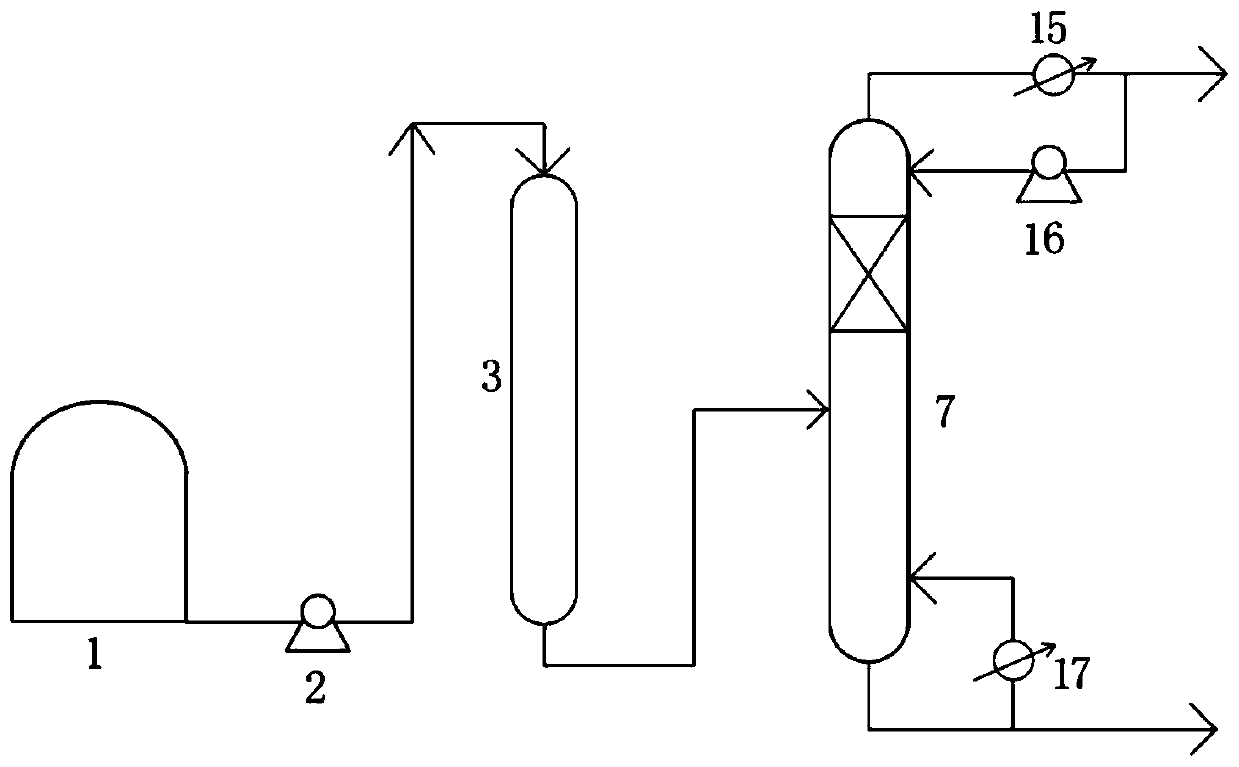

Method used

Image

Examples

Embodiment 1

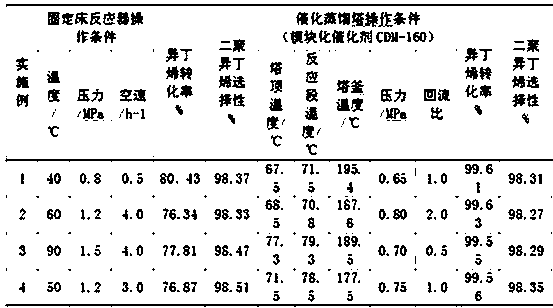

[0037] The above-mentioned catalyst D is specifically used in Example 1, the above-mentioned catalyst G is specifically used in Example 2, the above-mentioned catalyst A is specifically used in Example 3, and the above-mentioned catalyst E is specifically used in Example 4; wherein, The catalyst loading in the fixed bed reactor is 40 ml, and the catalyst loading in the catalytic distillation column is 100 ml.

[0038] The test conditions and results are shown in Table 1:

[0039] Table 1

[0040]

Embodiment 5

[0042] The above-mentioned catalyst D is specifically used in Example 5, the above-mentioned catalyst G is specifically used in Example 6, the above-mentioned catalyst A is specifically used in Example 7, and the above-mentioned catalyst E is specifically used in Example 8; wherein, The catalyst loading amount in the fixed bed reactor is 40ml, and the catalyst loading amount in the catalytic distillation column is 100ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com