Preparation method of low molecular weight chitosan

A low-molecular-weight, chitosan technology, applied in the field of chitosan degradation, can solve the problems of wide molecular weight distribution of products, large irradiation dose of low-molecular-weight chitosan, etc., which is beneficial to physiological activity, shortens irradiation time, molecular weight Narrow distribution of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

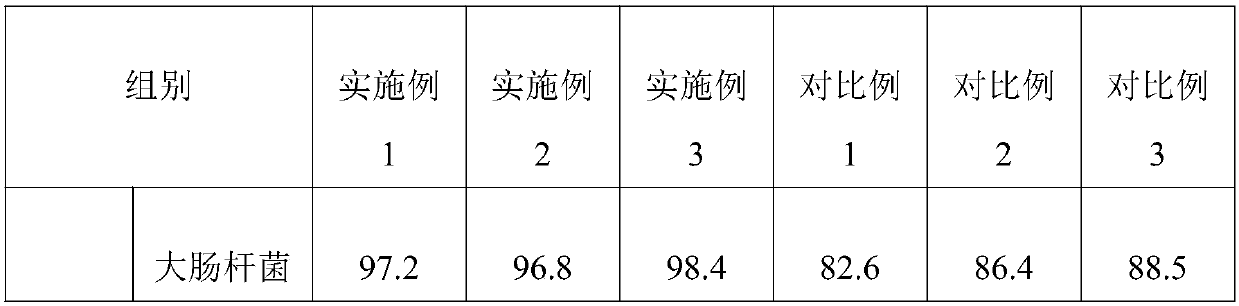

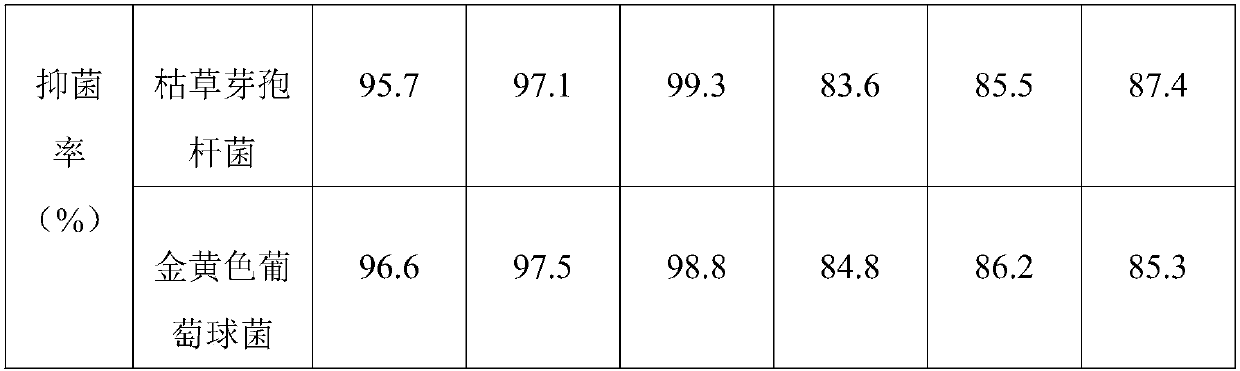

Examples

Embodiment 1

[0034] Embodiment 1, a kind of preparation method of low molecular weight chitosan

[0035] The preparation method of described low molecular weight chitosan, comprises the following steps:

[0036] S1 Take a hydrogen peroxide solution with a mass concentration of 5%, add water-soluble humic acid, the quality of the water-soluble humic acid is 0.2% of the above-mentioned hydrogen peroxide solution, and stir evenly to obtain a mixed solution;

[0037] S2 immersing chitosan in the mixed solution obtained in step S1, the mass concentration of chitosan is 25%, soaking for 30min, filtering to obtain filter residue;

[0038]S3 freezes the filter residue obtained in step S2 three times, the first freezing temperature is -4°C, the first freezing time is 2h, the second freezing temperature is -10°C, the second freezing time is 1h, and the third freezing time is -10°C. The freezing temperature is -19°C, and the third freezing time is 40 minutes. After thawing, dry the thawed filter res...

Embodiment 2

[0041] Embodiment 2, a kind of preparation method of low molecular weight chitosan

[0042] The preparation method of described low molecular weight chitosan, comprises the following steps:

[0043] S1 Take a hydrogen peroxide solution with a mass concentration of 12%, add water-soluble humic acid, the quality of the water-soluble humic acid is 0.6% of the above-mentioned hydrogen peroxide solution, and stir evenly to obtain a mixed solution;

[0044] S2 immersing chitosan in the mixed solution obtained in step S1, the mass concentration of chitosan is 35%, soaking for 50min, filtering to obtain filter residue;

[0045] S3 freezes the filter residue obtained in step S2 three times, the first freezing temperature is -4°C, the first freezing time is 4h, the second freezing temperature is -10°C, the second freezing time is 3h, and the third freezing time is -10°C. The freezing temperature is -19°C, and the third freezing time is 60 minutes. After thawing, dry the thawed filter r...

Embodiment 3

[0048] Embodiment 3, a kind of preparation method of low molecular weight chitosan

[0049] The preparation method of described low molecular weight chitosan, comprises the following steps:

[0050] S1 Take a hydrogen peroxide solution with a mass concentration of 10%, add water-soluble humic acid, the quality of the water-soluble humic acid is 0.4% of the above-mentioned hydrogen peroxide solution, and stir evenly to obtain a mixed solution;

[0051] S2 immersing chitosan in the mixed solution obtained in step S1, the mass concentration of chitosan is 30%, soaking for 40min, filtering to obtain filter residue;

[0052] S3 freezes the filter residue obtained in step S2 three times, the first freezing temperature is -4°C, the first freezing time is 3h, the second freezing temperature is -10°C, the second freezing time is 2h, and the third freezing time is -10°C. The freezing temperature is -19°C, and the third freezing time is 50 minutes. After thawing, dry the thawed filter r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com