Preparation method for fruit flavor-type pomegranate liqueur

A liqueur and fruit-flavored technology, which is applied in the field of preparation of fruit-flavored pomegranate liqueur, can solve the problems of insufficient fruity aroma, inconspicuous alcoholic flavor, and prominent alcoholic flavor, so as to achieve elegant aroma, ensure color, aroma, and Smooth and balanced taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the fruit-flavored pomegranate liqueur provided by the present invention comprises the following steps: (1) using fresh and mature Huili Qingpi soft-seed pomegranate (sweet pomegranate) as raw material to prepare sweet pomegranate juice with a sugar content of 13-16% Standby; use fresh and ripe Huili sour pomegranate as raw material to prepare sour pomegranate juice with a sugar content of 10-13% for use; use local pomegranate flowers in Huili to prepare pomegranate nectar with a sugar content of 65%-75% for use; process The remaining pomegranate peel of the pomegranate juice is used to make pomegranate peel distilled wine with an alcohol content of 60-65°; 77%, sour pomegranate juice 8-15%, pomegranate nectar 15-20%; (3) add sulfur dioxide and pectinase to the mixed solution in step (2), carry out color protection and enzymolysis to the fruit, and obtain the density For the fermentation broth of 1105-1115, 200-300 mg / L active dry yeast Sacchar...

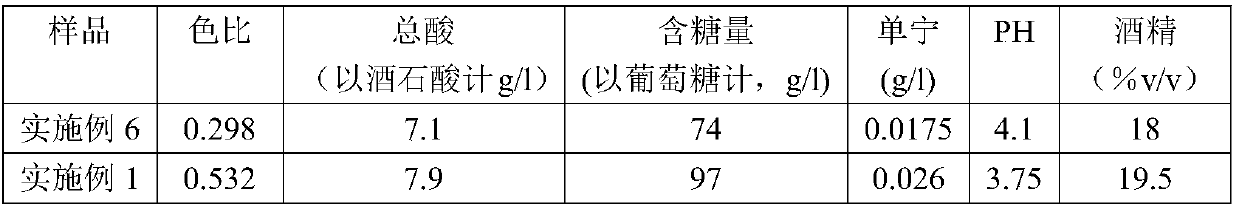

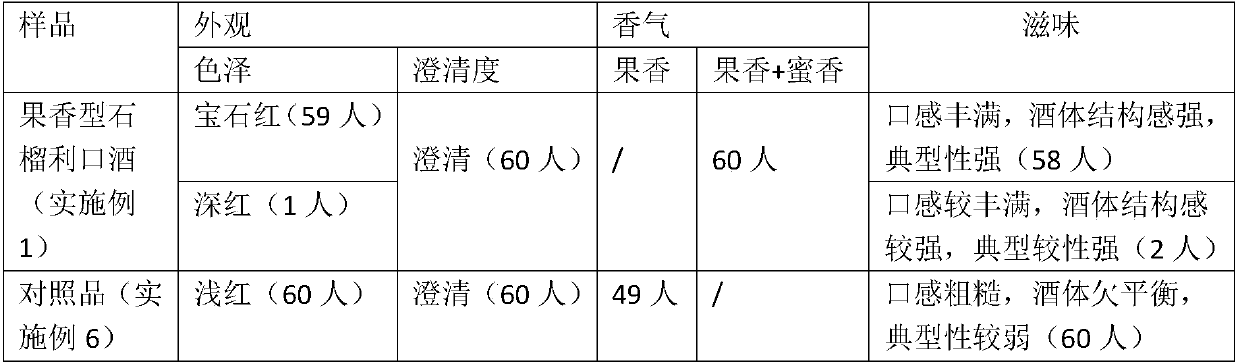

Embodiment 1

[0037] Mix 65L of sweet pomegranate juice, 15L of sour pomegranate juice, and 20L of pomegranate nectar; the sugar content of sweet pomegranate juice is 14%, the sugar content of sour pomegranate juice is 10%, and the sugar content of pomegranate nectar is 65%, and the obtained density is 1110g / L of fermentation broth, add 6g of sulfur dioxide and 3g of pectinase, then inoculate 20g of low-temperature yeast, control the fermentation temperature at 14°C, and ferment for 20 days. At this time, the density of the fermentation broth is reduced to about 1060g / L. Lower the temperature to 5°C, separate the sediment at the bottom of the fermentation tank, transfer the original wine to another clean container, and add 18L of pomegranate peel distilled wine with an alcohol content of 65° to stop the fermentation. The original wine after the termination of fermentation is separated into another clean storage tank for aging, and the original wine aged for one year is purified and clarifie...

Embodiment 2

[0039] Mix 72L of sweet pomegranate juice, 9L of sour pomegranate juice, and 19L of pomegranate nectar; wherein the sugar content of sweet pomegranate juice is 14.3%, the sugar content of sour pomegranate juice is 11.2%, and the sugar content of pomegranate nectar is 65%. The obtained density is 1112g / L of fermentation broth, add 6g sulfur dioxide and 3g pectinase, then inoculate 20g of low-temperature yeast, control the fermentation temperature at 15°C and ferment for 18 days. At 6°C, separate the sediment at the bottom of the fermentation tank, transfer the original wine to another clean container, and add 19L of pomegranate peel distilled wine with an alcohol content of 65° to stop the fermentation. The original wine after the termination of fermentation is separated into another clean storage tank for aging, and the original wine aged for one year is purified and clarified. After clarification, the original wine is filtered with diatomaceous earth and frozen. The freezing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com