Preparation method of desizing and scouring compound enzyme

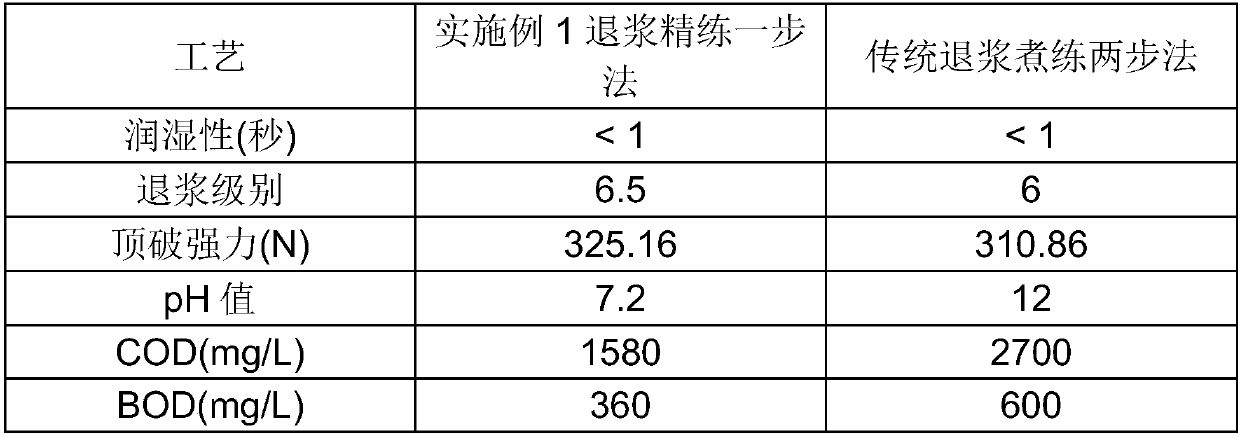

A complex enzyme and refining technology, applied in the field of complex enzymes, can solve the problems of long pretreatment process route, increase the burden of sewage treatment, and large consumption of chemical substances, so as to change the status quo of production process, reduce waste water discharge, process energy saving and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a preparation method of desizing and refining compound enzyme, the specific steps are as follows:

[0041] (1) Put 65-95 parts of pure water in a clean stirring tank and start stirring;

[0042] (2) Add 12-35 parts of enzyme stabilizer and 2-6 parts of enzyme activity accelerator, and stir at 400-800 rpm for 20-30 minutes until completely mixed;

[0043] (3) Add 0.1-1 part of fungicide, stir at 400-800 rpm for 20-30 minutes until completely mixed;

[0044] (4) Detect the pH of the solution, use 0.1-1 part of pH regulator (diluted acetic acid solution and NaOH solution), adjust the pH of the solution to a suitable pH value;

[0045] (5) Under the condition that the temperature of the solution does not exceed 30°C, add 3-9 parts of amylase and 2-6 parts of pectinase, and stir for 20-30 minutes at a speed of 400-800 rpm until completely mixed;

[0046] (6) Stop stirring to obtain the prepared liquid desizing and refining compound enzyme;

[0047] ...

Embodiment 1

[0049] A desizing and refining compound enzyme, the preparation method of the desizing and refining compound enzyme is:

[0050] (1) Put 65 parts of pure water into a clean stirring tank and start stirring;

[0051](2) Add 12 parts of 1,3-propanediol and 2 parts of anhydrous calcium chloride, and stir for 20 minutes at a speed of 400 rpm until completely dissolved;

[0052] (3) Add 0.2 parts of 1,2-benzisothiazolin-3-one, and stir for 20 minutes at a speed of 400 rpm until completely mixed;

[0053] (4) Detect the pH of the solution, add 0.2 parts of glacial acetic acid, and stir at a speed of 400 rpm for 20 minutes until completely mixed, and adjust the pH value of the solution to 5.5; the glacial acetic acid is diluted in an airtight container before use 20% acetic acid solution;

[0054] (5) Ensure that the temperature of the solution in the stirred tank does not exceed 30°C;

[0055] (6) When the temperature of the solution in the stirred tank is lower than 30°C, add 3 ...

Embodiment 2

[0059] A desizing and refining compound enzyme, the preparation method of the desizing and refining compound enzyme is:

[0060] (1) Put 95 parts of pure water into a clean stirring tank and start stirring;

[0061] (2) Add 36 parts of 1,3-propanediol and 6 parts of anhydrous calcium chloride, and stir for 30 minutes at a speed of 800 rpm until completely dissolved;

[0062] (3) Add 1 part of 1,2-benzisothiazolin-3-one, stir at 800 rpm for 30 minutes until completely mixed;

[0063] (4) Detect the pH of the solution, add 1 part of glacial acetic acid, and stir at a speed of 800 rpm for 30 minutes to completely mix, and adjust the pH value of the solution to 6.2; the glacial acetic acid is diluted in an airtight container before use 20% acetic acid solution;

[0064] (5) Ensure that the temperature of the solution in the stirred tank does not exceed 30°C;

[0065] (6) When the temperature of the solution in the stirred tank is lower than 30°C, add 9 parts of amylase and 6 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com