A kind of preparation method of elastic anti-aging plastic rope

An anti-aging, plastic technology, applied in the field of plastic rope, can solve the problems of easy aging, etc., and achieve the effect of enhancing elasticity and anti-aging, high wear resistance and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

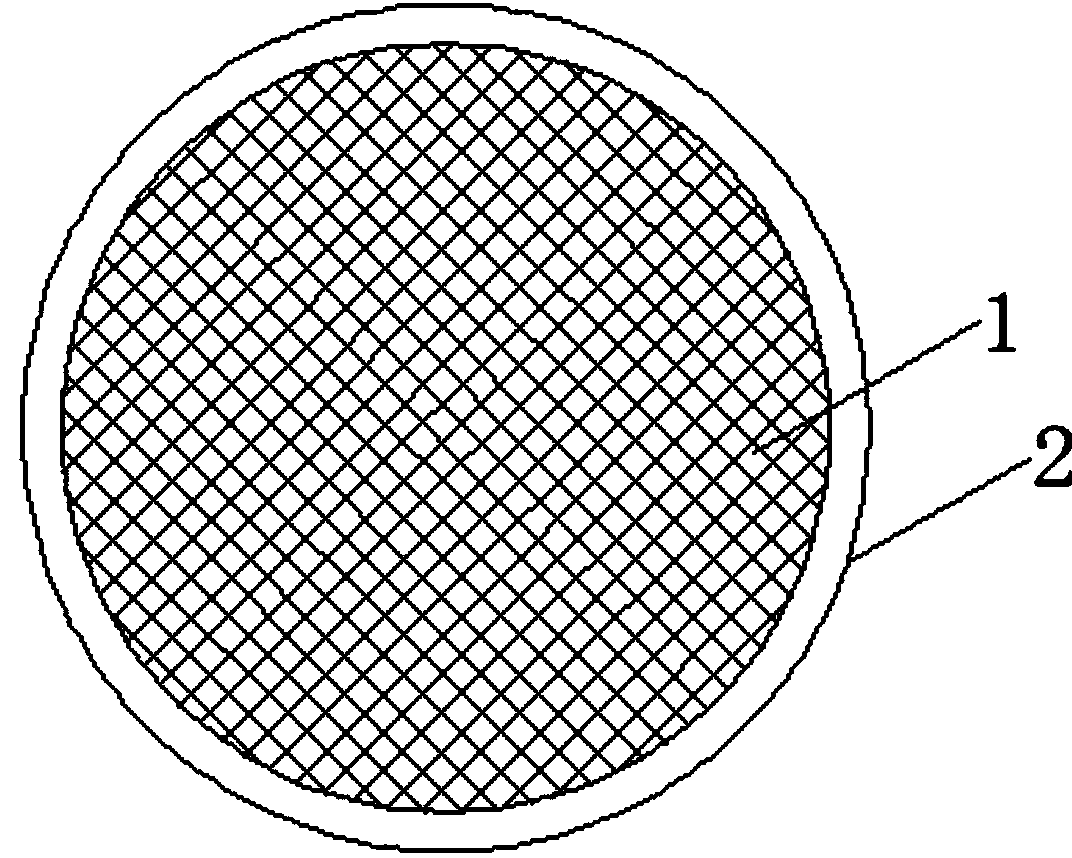

[0021] Such as figure 1 As shown, an elastic anti-aging plastic rope includes a rope body (1) and an EPDM layer (2);

[0022] The rope body (1) is formed by twisting polypropylene fibers and polyamide fibers, and the surface of the rope body (1) is covered with a EPDM layer (2).

[0023] Preferably, the ratio of the number of strands of the polypropylene fiber to the polyamide fiber is 9:1.

[0024] A preparation method of an elastic anti-aging plastic rope, comprising the steps of:

[0025] (1) Preparation of anti-aging EPDM layer: adjust the roller temperature of the rubber mill at 30 ° C, and successively mix the EPDM matrix, graphene, triethylenediamine, trimellitate and The compound of ammonium bicarbonate and dihydroquinoline were put into the open mill and mixed for 23 minutes; the roller distance of the open mill was adjusted to 0.6 mm, N-phenyl-N'-cyclohexyl-p-phenylenediamine was added, pounded , mixed for 6 minutes; then adjust the roller distance of the open mil...

Embodiment 2

[0029] Such as figure 1 As shown, an elastic anti-aging plastic rope includes a rope body (1) and an EPDM layer (2);

[0030] The rope body (1) is formed by twisting polypropylene fibers and polyamide fibers, and the surface of the rope body (1) is covered with a EPDM layer (2).

[0031] Preferably, the ratio of the number of strands of the polypropylene fiber to the polyamide fiber is 9:1.

[0032] A preparation method of an elastic anti-aging plastic rope, comprising the steps of:

[0033] (1) Preparation of anti-aging EPDM layer: adjust the roller temperature of the rubber mill at 45 ° C, and successively mix the EPDM matrix, graphene, dibutyltin dilaurate, and trimellitate The compound with ammonium bicarbonate and 2,6-tertiary butyl-4-methylphenol are put into the mill and mixed for 26min; adjust the roller distance of the mill to 1.0mm, add N-phenyl- α-aniline, tamping, kneading for 9 min; then adjust the roller distance of the open mill to 4mm, and continue kneading ...

Embodiment 3

[0037] Such as figure 1 As shown, an elastic anti-aging plastic rope includes a rope body (1) and an EPDM layer (2);

[0038] The rope body (1) is formed by twisting polypropylene fibers and polyamide fibers, and the surface of the rope body (1) is covered with a EPDM layer (2).

[0039] Preferably, the ratio of the number of strands of the polypropylene fiber to the polyamide fiber is 9:1.

[0040] A preparation method of an elastic anti-aging plastic rope, comprising the steps of:

[0041] (1) Preparation of anti-aging EPDM layer: adjust the roller temperature of the rubber mill at 60 ° C, and successively mix the EPDM matrix, graphene, sodium dimethyldithiocarbamate, and partial phenylene The compound of triester and ammonium bicarbonate, and dihydroquinoline were put into the open mill and mixed for 29 minutes; the roller distance of the open mill was adjusted to 1.4mm, and N-phenyl-N'-cyclohexylterephthalene was added Amine, tamping, and mixing for 13 minutes; then adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com