Direct current electric energy conversion method and system with DCDC module automatic conversion function

A DC power and automatic switching technology, which is applied in the direction of converting DC power input to DC power output, power network operating system integration, and adjusting electrical variables. It can solve the problem of large inductor volume, large inductor saturation current, and small inductor peak current. minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

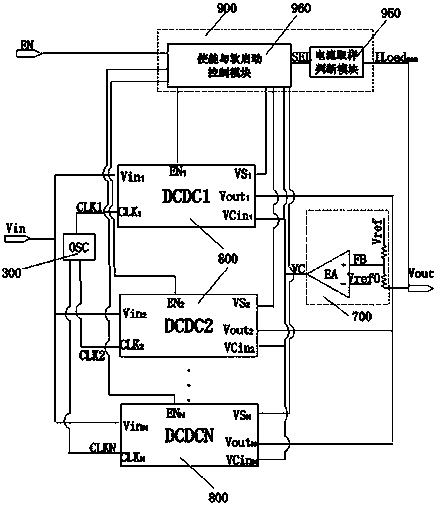

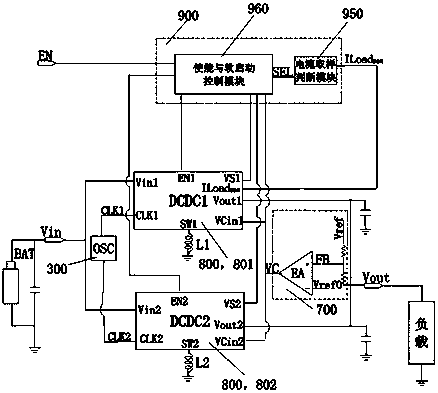

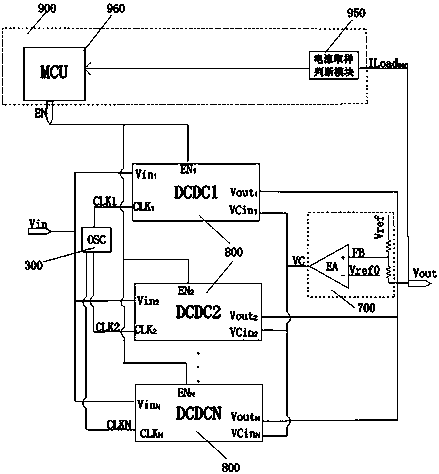

[0052] like figure 1 A direct current power conversion method for automatic switching of DCDC modules is shown, comprising the following steps:

[0053] A: Set N in parallel for the input DC voltage V in converted to the output voltage V out The DCDC module 800, N is the number of the current power conversion module 800, and the value of N is a natural number ranging from 1 to M; it is set for the output voltage V out The output voltage detection and feedback module 700 for detection and feedback is used to provide the working clock signal CLK for N DCDC modules 800 at the same time N The clock signal module 300; the value of M can be any value between 2 and 100, of course, the more commonly used values of M are 2, 3, 4, 6, 8 and 10;

[0054] B: The output voltage detection feedback module 700 samples the output voltage and compares it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com