Method for preparing SAPO molecular sieve containing copper and silver bimetal and application thereof

A molecular sieve and bimetallic technology, applied in the field of catalyst synthesis, can solve the problems of low-temperature hydrothermal stability and activity decline, and achieve the effects of reducing production costs, reducing energy consumption, and improving conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of SAPO-34 molecular sieve raw powder:

[0043] According to the method described in [Document 1], diethylamine was used as an organic template (abbreviated as DEA), and the sample was dried at 120°C to obtain the original SAPO-34 molecular sieve powder.

[0044] 【Document 1】: Microporous and Mesoporous Materials, 2008, 114(1-3), 416-423.

[0045] Preparation of SAPO-18 molecular sieve powder O18-1:

[0046] According to the method described in [Document 2], N,N-diisopropylethylamine was used as an organic template, and the sample was dried at 120°C to obtain the raw SAPO-18 molecular sieve powder.

[0047] 【Document 2】: Journal of Physical Chemistry, 1994, 98(40), 10216-10224.

[0048] Preparation of DNL-6 molecular sieve raw powder:

[0049] According to the method described in [Document 3], diethylamine was used as a template, and the sample was dried at 120°C to obtain the DNL-6 molecular sieve powder.

[0050] 【Document 3】: Microporous and Mes...

Embodiment 1

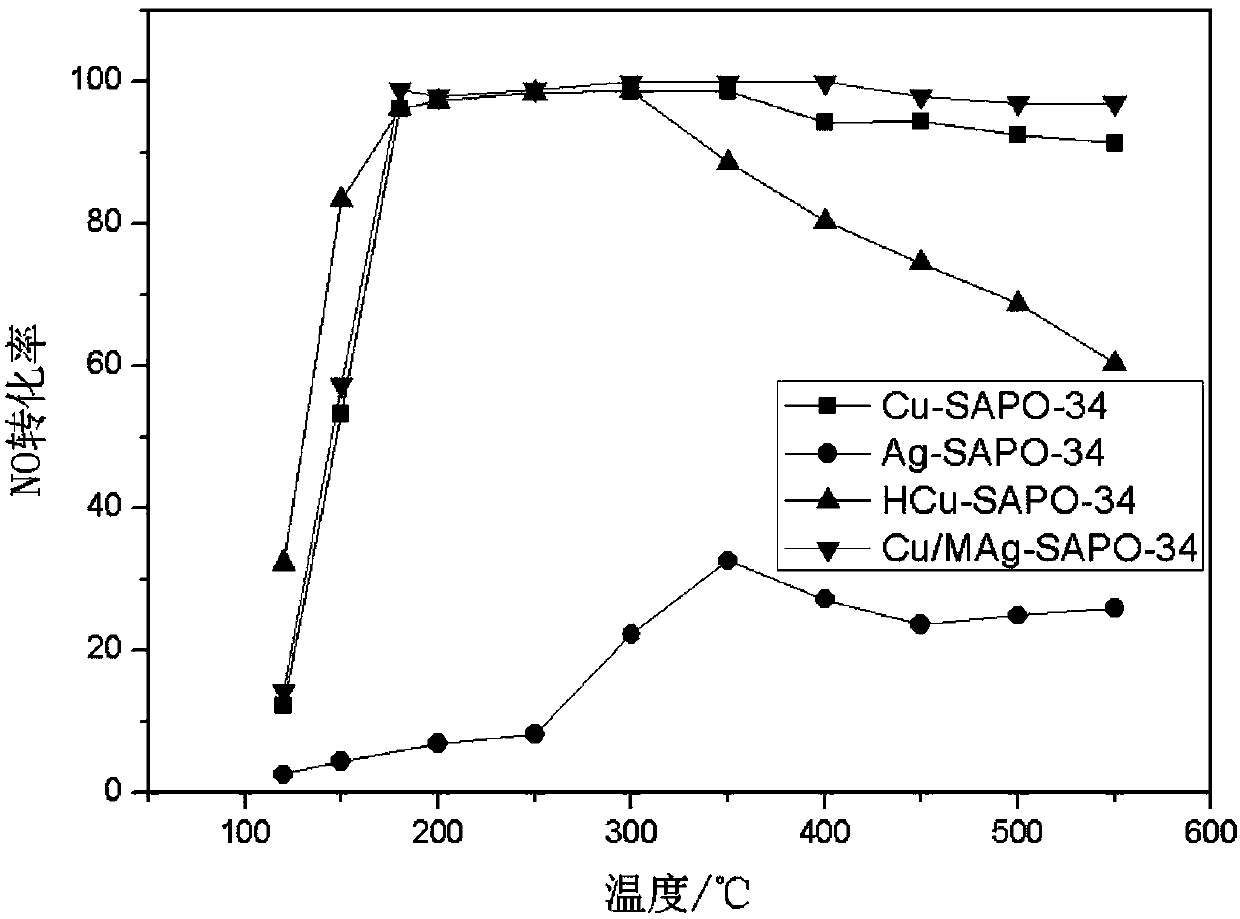

[0066] The preparation of embodiment 1 Cu-SAPO-34 former powder sample

[0067] With Cu(CH 3 COO) 2 ·H 2 O is the copper source, prepare an aqueous solution with a concentration of 0.01mol / L, put 10g of SAPO-34 molecular sieve raw powder into 220ml of copper ion solution according to the solid-to-liquid ratio of 1:22, stir for 5 minutes, and heat up to 50°C. Exchange 4h. Then it was separated by centrifugation, washed three times with deionized water, and dried at 80° C. to obtain the Cu-SAPO-34 raw powder sample. The mass content of copper oxide in the molecular sieve was determined by XRF to be 1.78 wt%. The XRD results show that the XRD patterns of Cu-SAPO-34 raw powder sample and SAPO-34 molecular sieve raw powder are basically the same, that is, the peak positions are the same, and the peak intensities are slightly different.

Embodiment 2

[0068] The preparation of the former powder sample of embodiment 2 HCu-SAPO-34

[0069] With Cu(CH 3 COO) 2 ·H 2 O is the copper source, prepare an aqueous solution with a concentration of 0.02mol / L, put 10g of SAPO-34 molecular sieve raw powder into 250ml of copper ion solution according to the solid-to-liquid ratio of 1:25, stir for 5 minutes, and then heat up to 50°C. Exchange 4h. Then it was separated by centrifugation, washed three times with deionized water, and dried at 80° C. to obtain the raw powder sample of HCu-SAPO-34. The mass content of copper oxide in the molecular sieve was determined by XRF to be 4.96 wt%. The XRD results show that the XRD spectra of the HCu-SAPO-34 raw powder sample and the SAPO-34 molecular sieve raw powder are basically consistent, that is, the peak positions are the same, and the peak intensities are slightly different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com