Asphalt composition and preparation method thereof

A technology of asphalt composition and matrix asphalt, which is applied in building structures, building components, building insulation materials, etc., can solve the problem of poor fuel and oil dissolution and erosion ability, low performance at high and low temperature, and can not meet the needs of use. and other problems, to achieve the effects of good storage stability, easy melting, excellent resistance to fuel and oil dissolution and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment:

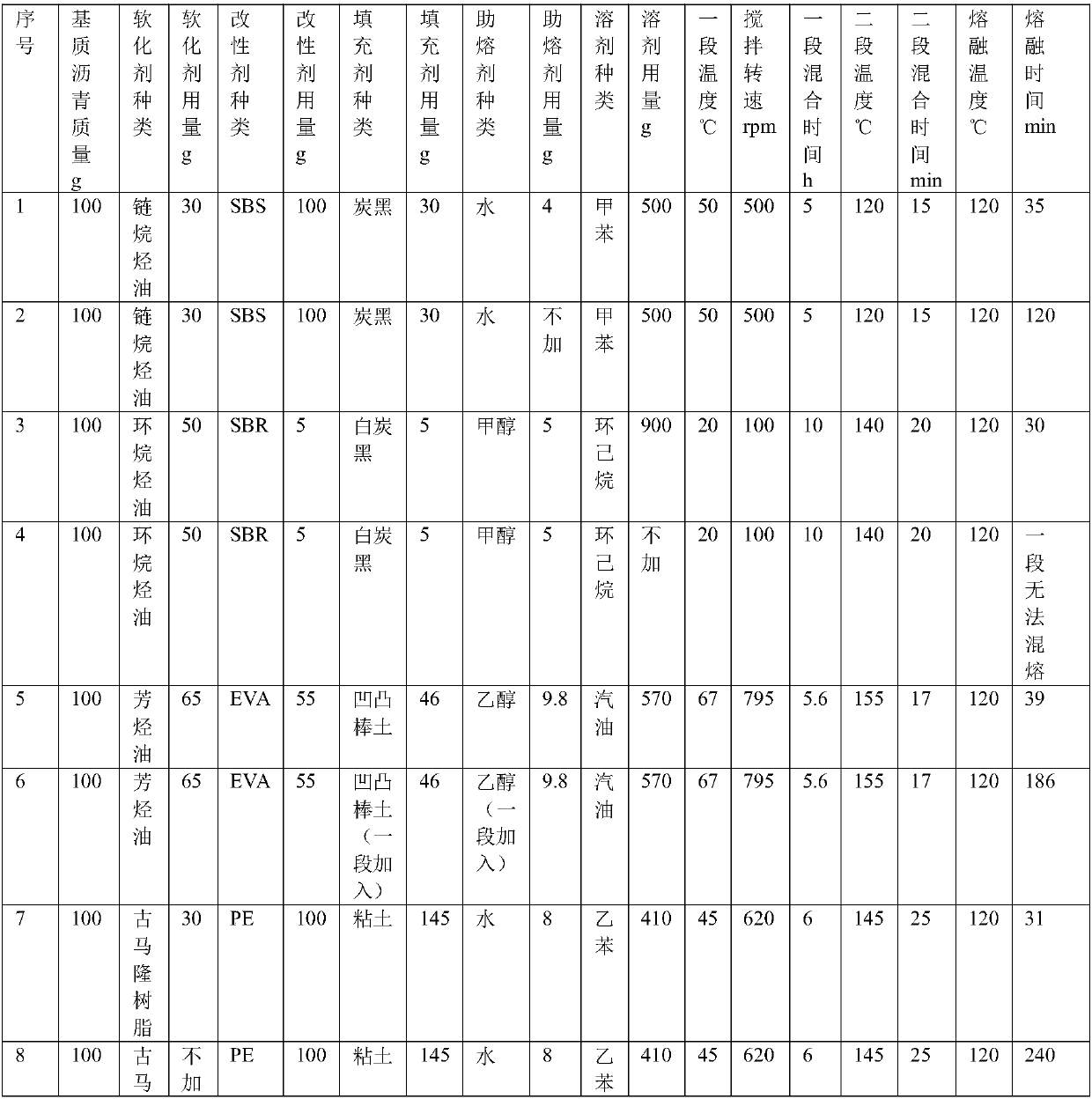

[0020] According to the table below, select paraffin oil, naphthenic oil, aromatic oil, coumarone resin, pine tar as softener, SBS, SBR, EVA, PE as modifier, carbon black, white carbon black, attapulgite, Clay, calcium carbonate powder, and calcium carbonate particles are used as fillers, water, methanol, and ethanol are used as fluxes, and toluene, cyclohexane, gasoline, ethylbenzene, and hexane are used as solvents.

[0021] Weigh the mass of base asphalt to 100g, introduce the solvent into a closed mixing tank, control the reaction temperature of a stage at 20-80°C, and stir at a speed of 100-800rpm, add base asphalt, softener and modifier in sequence for mixing, and the mixing time is 5 -12h, the toluene in the material is extracted after mixing, the second stage reaction temperature is raised to 120-160°C, filler and flux are added for mixing, the mixing time is 15-30min, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com