A pressure-sensitive chemical plugging agent for channeling and leakage sealing

A technology of pressure-sensitive chemistry and plugging agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low bonding strength of solidified body, poor retention, and low success rate of plugging at one time, and achieve strong Residency and anti-channeling ability, increase in filtration speed, and increase the effect of filtration water loss speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

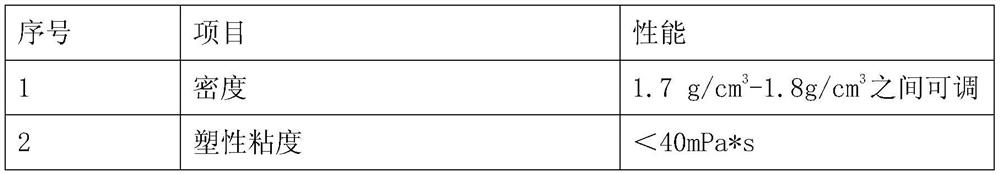

[0027] Embodiment 1 prepares pressure-sensitive chemical plugging agent

[0028] The components are: 88% aluminate superfine cement, 6% metal oxide nano-filler, 0.2% suspension stabilizer wood calcium, 1.8% algae chert, 1.4% fiber bridging agent, micro-expansion agent plus Amount 2.6%.

[0029] The particle size of the aluminate superfine cement is 20-50 μm.

[0030] The metal oxide is Al 2 o 3 , the particle size is 0.02~1um.

[0031] The fibers are wood fibers.

[0032] The algae chert is prepared by the following method: take diatomite, bentonite and perlite, mix them, and the mass ratio of diatomite, bentonite and perlite is 8:1:1; then pulverize, Calcined at 1500°C for 2 hours, cooled to room temperature, and finally ground the clinker (after grinding, 95% of the total amount of the mixture with a particle size not greater than 35 μm was obtained).

[0033] The micro-expansion agent is prepared by mixing CaO and sulfate in a molar ratio of 1:1. The sulfate is CaSO 4...

Embodiment 2

[0036] Embodiment 2 prepares pressure-sensitive chemical plugging agent

[0037] The components are as follows: 88% of aluminate superfine cement, 8% of metal oxide, 0.2% of wood calcium, 1.8% of algae siliceous rock, 1.4% of fiber, and 2.7% of micro expansion agent.

[0038] The particle size of the aluminate superfine cement is 20-50 μm.

[0039] The metal oxide is Fe 2 o 3 , the particle size is 0.02~1um.

[0040] The fibers are wood fibers.

[0041] The algal chert is prepared by the following method: take diatomite, bentonite and perlite, mix them, and the mass ratio of diatomite, bentonite and perlite is 7.5:1.2:0.8; then pulverize, Calcined at 1500°C for 2 hours, cooled to room temperature, and finally ground the clinker (after grinding, 95% of the total amount of the mixture with a particle size not greater than 35 μm was obtained).

[0042] The micro-expansion agent is formed by mixing MgO and sulfate in a molar ratio of 0.8:1.2. The sulfate is CaSO 4 0.5H 2 O...

Embodiment 3

[0044] Embodiment 3 preparation pressure-sensitive chemical plugging agent

[0045] The components are as follows: 91% of aluminate superfine cement, 4% of metal oxide, 0.4% of wood calcium, 1.2% of algae siliceous rock, 1.8% of fiber, and 1.5% of micro expansion agent.

[0046] The particle size of the aluminate superfine cement is 20-50 μm.

[0047] The metal oxide is TiO 2 , the particle size is 0.02~1um.

[0048] The fibers are wood fibers.

[0049] The algal chert is prepared by the following method: take diatomite, bentonite and perlite, mix them, and the mass ratio of diatomite, bentonite and perlite is 8.5:0.8:1.2; then pulverize, Calcined at 1500°C for 2 hours, cooled to room temperature, and finally ground the clinker (after grinding, 95% of the total amount of the mixture with a particle size not greater than 35 μm was obtained).

[0050] The micro-expansion agent is prepared by mixing CaO and sulfate in a molar ratio of 1.2:0.8. The sulfate is CaSO 4 0.5H 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com