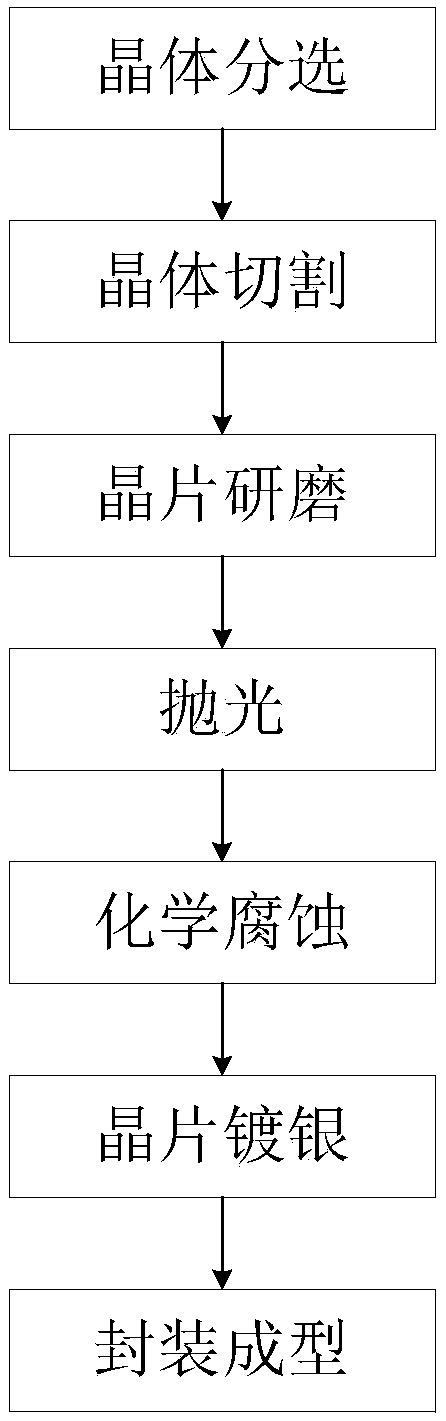

Method for machining quartz crystal resonator

A technology of quartz crystal and processing method, applied in electrical components, impedance networks, etc., can solve the problems of regional errors covered by masks, high loss rate of silver materials, low processing accuracy, etc., to reduce processing and manufacturing costs, matching tolerance Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

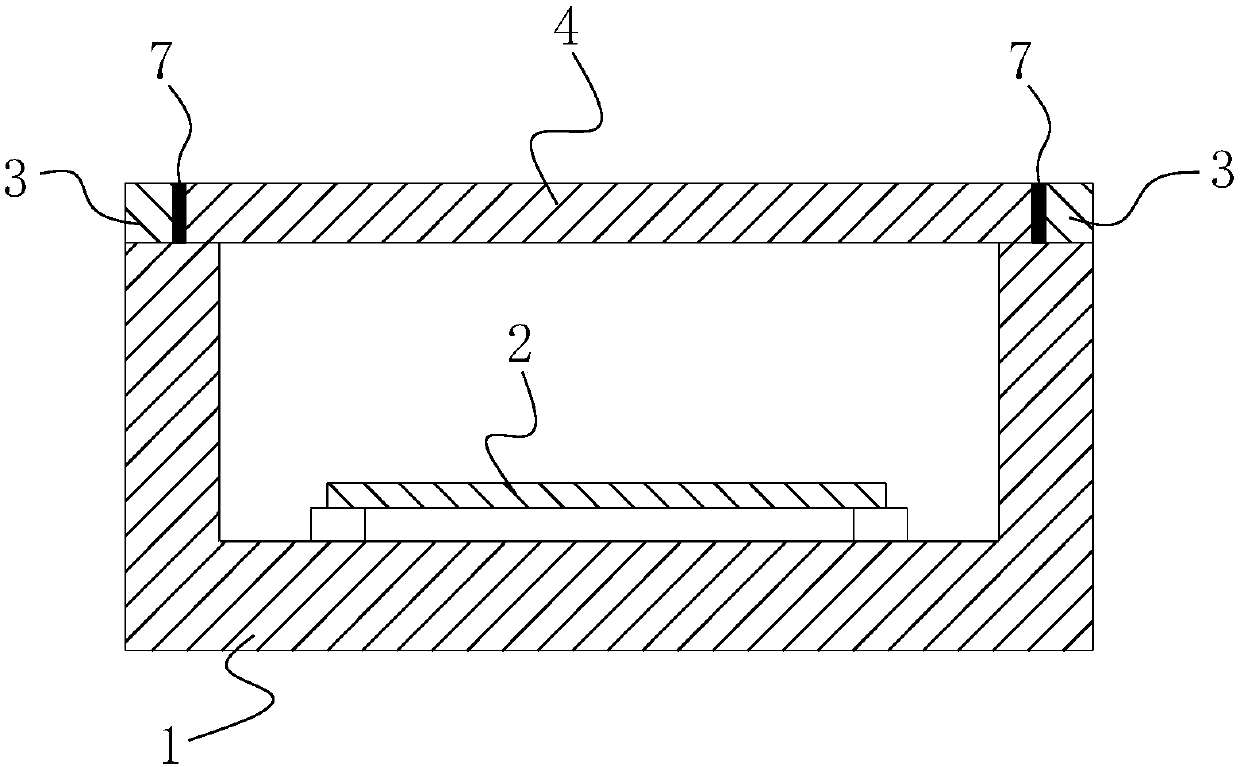

[0048] like Figure 9 As shown, the metal Kovar ring 3 includes an inner ring and an outer ring that form an integral body, the top surface of the metal Kovar ring 3 is stepped, and the height of the top surface of the inner ring of the metal Kovar ring 3 is lower than that of the outer ring. The height of the top surface of the ring, the metal cover plate 4 is arranged on the top surface of the inner ring of the metal Kovar ring 3, and a gap is provided between the inner wall of the outer ring of the metal Kovar ring 3 and the outer wall of the metal cover plate 4.

[0049] Specifically, the inner ring and the outer ring are actually a whole, and only the height of the top surface is different.

[0050] like Figure 7 , 8, 9, the metal Kovar ring 3 in this embodiment is arranged on the upper part of the base 1. The outer circumferential dimension of the metal cover plate 4 is smaller than the inner dimension of the outer ring of the metal Kovar ring 3 , but larger than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com