Sewage treatment apparatus for chemical industry parks

A technology for sewage treatment equipment and chemical industrial parks, applied in the direction of oxidation water/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problem of poor biodegradability of high-salt advanced treatment sewage and failure to reach the first level of sewage discharge Standards, limited effects of biochemical processes, etc., to achieve the effect of strong salt tolerance, low cost, and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

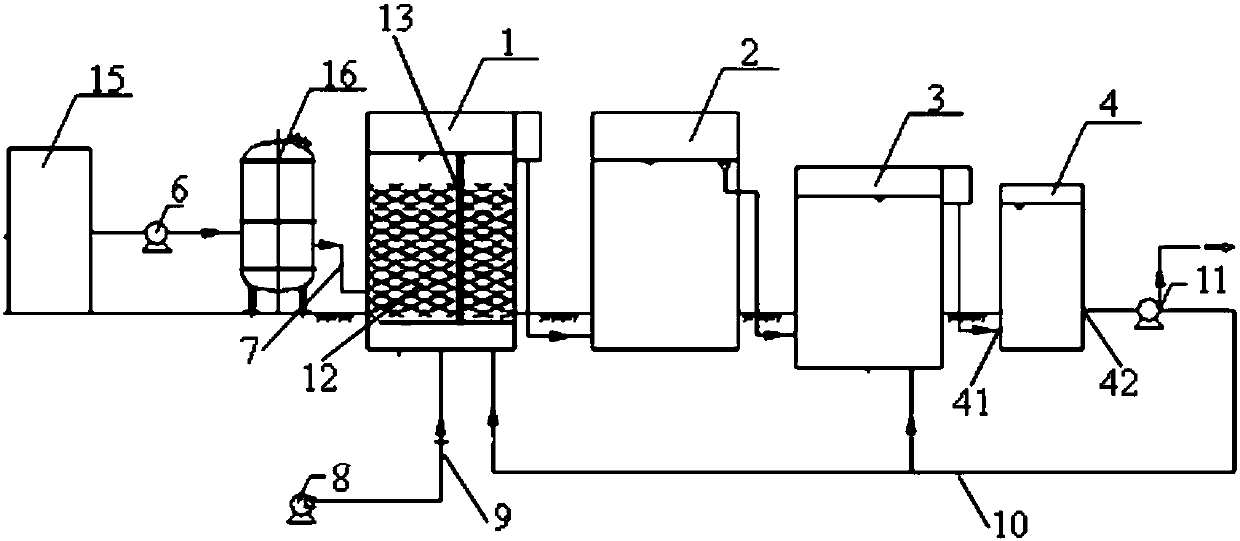

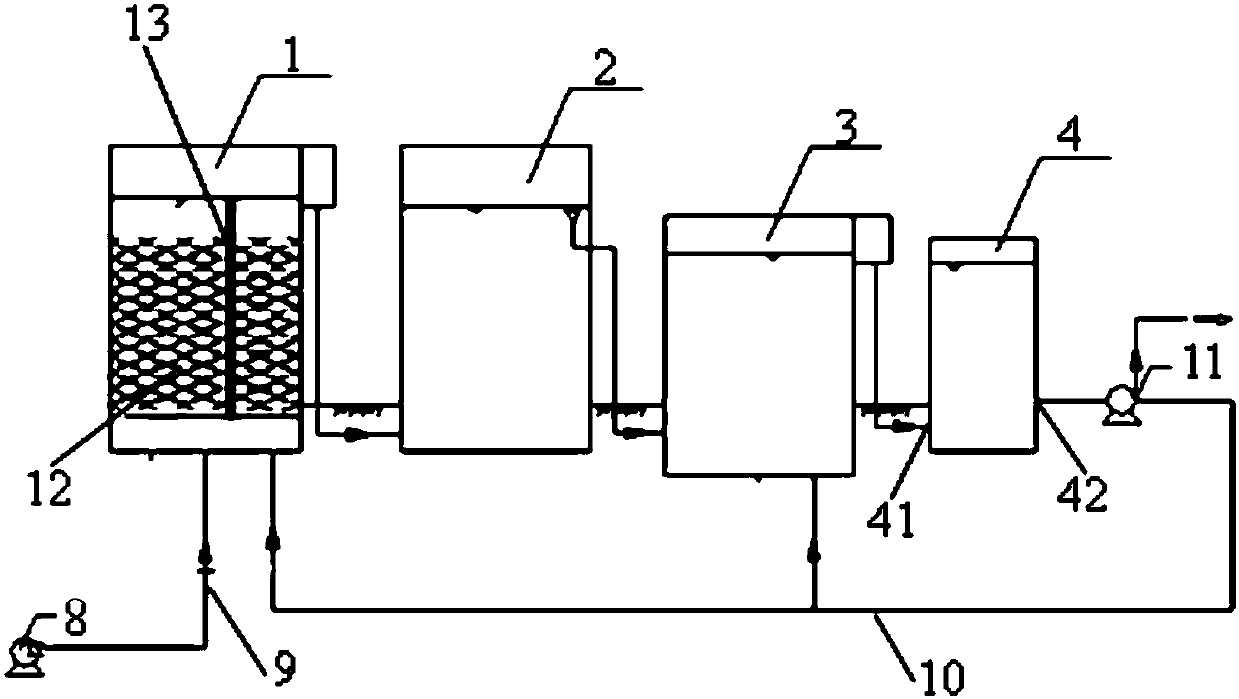

[0034] Embodiment 1~4: A kind of sewage treatment device that is used in chemical industrial park, comprises catalytic oxidation pond 1, oxidation stabilization pond 2, post-biochemical BAF pond 3, clear water pond 4, sump 15 and filter 16, described catalytic oxidation Pool 1, oxidation stabilization pool 2, post-biochemical BAF pool 3 and clear water pool 4 are connected through transmission pipeline 5 in turn, and described filter 16 is connected to catalytic oxidation pool 1 inside through water inlet pipeline 7, and an ozone generator 8 passes gas The pipeline 9 is connected to the inside of the catalytic oxidation tank 1, and the clean water tank 4 is provided with a water inlet 41 and a water outlet 42, and the water inlet 41 of the clean water tank 4 is connected with the post-biochemical BAF tank 3 through a transmission pipeline 5, so that The water outlet hole 42 of the clear water tank 4 is connected to one end of a backwash pump 11, and the other end of the backwas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com