Ceramic mobile-phone rear cover and preparation method thereof

A mobile phone back cover and ceramic technology, which is applied in the field of high-toughness ceramic mobile phone back cover and its preparation, can solve the problems of complex molding process, low toughness and strength, and failure to meet the fracture toughness of the mobile phone back cover, and achieve high dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041]The invention provides a preparation method of a ceramic mobile phone back cover, comprising:

[0042] (1) Use a solvent to make yttria-stabilized zirconia powder into a suspension, add a dispersant to the suspension, add alumina powder, mix evenly and dry to obtain doped modified zirconia powder. Yttrium stabilized zirconia powder;

[0043] Using a solvent to formulate the alumina powder into a suspension, adding a dispersant and a sintering aid to the suspension, mixing uniformly and then drying to obtain a doped modified alumina powder;

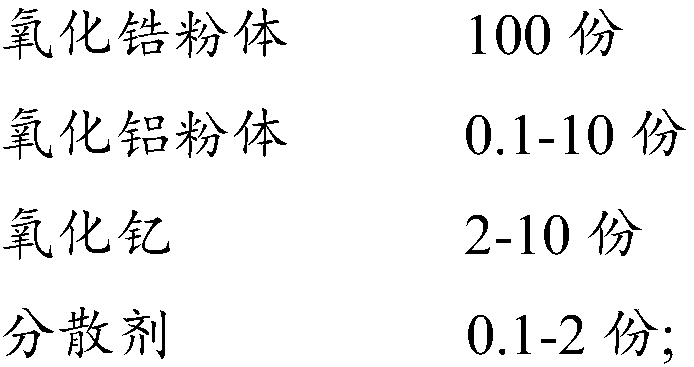

[0044] The ceramic mobile phone back cover can use zirconia powder as the main raw material, and can also use alumina powder as the main raw material. When the ceramic mobile phone back cover uses zirconia powder as the main raw material, its raw material formula in parts by weight is as follows:

[0045]

[0046] The zirconia powder and alumina powder are made of sub-micron powder, and the cost is relatively low. Cooperating wit...

Embodiment example 1

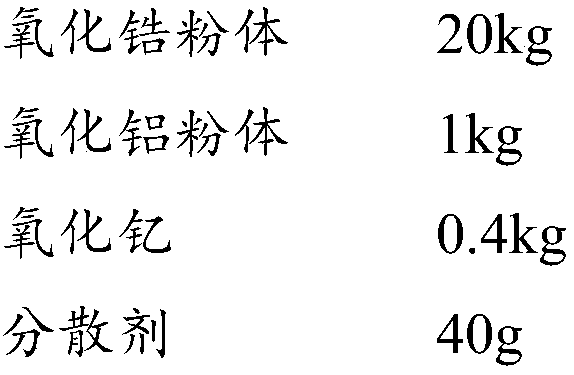

[0075] (1) Formula

[0076]

[0077] (2) Preparation method

[0078] (1) Preparation of doped modified high-purity zirconia powder

[0079] Weigh the yttria-stabilized high-purity zirconia powder, use deionized water as the solvent, prepare the yttria-stabilized high-purity zirconia powder into a suspension with a solid content of 45%, and add BYK to the suspension to disperse agent, with Al(NO 3 ) 3 .6H 2 O way to join Al 2 o 3 . Then, using ZrO 2 50 kg of balls were used as the ball milling medium, milled in a ball mill tank for 12 hours, mixed evenly, and then spray-dried to obtain doped and modified high-purity zirconia powder.

[0080] (2) Atmospheric pressure and low temperature sintering

[0081] The modified zirconia powder obtained in step (1) was placed in a dry pressing mold, and formed by dry pressing at 30 MPa, and then placed in a cold isostatic press, and held at 150 MPa for 2 minutes to obtain a ceramic green body. The ceramic green body was transf...

Embodiment example 2

[0087] (1) Formula

[0088]

[0089] (2) Preparation method

[0090] (1) Preparation of doped modified high-purity zirconia powder

[0091] Weigh the yttria-stabilized high-purity zirconia powder, use deionized water as the solvent, prepare the yttria-stabilized high-purity zirconia powder into a suspension with a solid content of 50%, add BYK to the above suspension agent, with Al(NO 3 ) 3 .6H 2 O way to join Al 2 o 3 . Then, using ZrO 2 50 kg of balls were used as the ball milling medium, milled in a ball mill tank for 12 hours, mixed evenly, and then spray-dried to obtain doped and modified high-purity zirconia powder.

[0092] (2) Atmospheric pressure and low temperature sintering

[0093] The modified zirconia powder obtained in step (1) was placed in a dry pressing mold, and formed by dry pressing at 30 MPa, and then placed in a cold isostatic press, and held at 150 MPa for 2 minutes to obtain a ceramic green body. The ceramic green body was transferred to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com