Light-mass and high-strength aluminum magnesium copper high-entropy alloy and preparation method thereof

A high-entropy alloy and high-strength technology, applied in the field of light-weight high-strength aluminum-magnesium-copper high-entropy alloy and its preparation, can solve the problems of high cost, high energy consumption, and increased energy consumption of alloy smelting, and achieve low cost and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

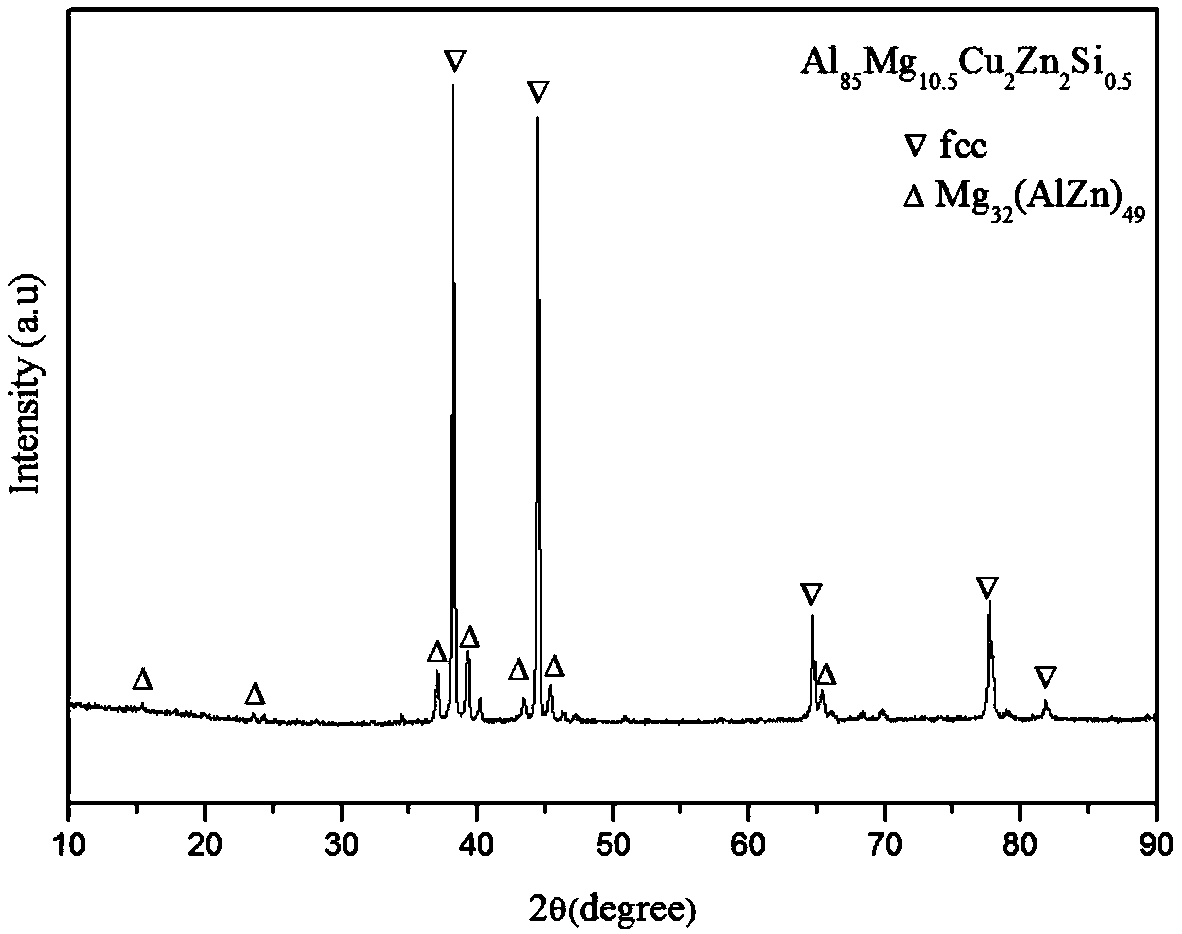

Image

Examples

Embodiment 1

[0023] The molecular formula of the lightweight high-strength aluminum-magnesium-copper high-entropy alloy of this example is Al 58.5 Mg 31.5 Cu 4.5 Zn 4.5 Si 1 , the preparation steps are as follows: the raw materials Al, Mg, Cu, Zn, Si with a purity greater than 99.9% are pressed by Al 58.5 Mg 31.5 Cu 4.5 Zn 4.5 Si 1 of ingredients to prepare 100g. Put the prepared raw materials into the graphite crucible in order of melting point from low to high, the element with the lowest melting point is placed at the bottom, and the element with the highest melting point is placed at the top. Put the graphite crucible filled with alloy materials into the spiral induction coil, evacuate to below 20Pa, and then fill with argon to 0.3MPa. Start the high-frequency induction device to control the induction heating current. After the alloy ingot melts, keep the alloy in a molten state for 30 minutes to make the alloy composition uniform. Cast the uniformly smelted alloy liquid into...

Embodiment 2

[0025] The molecular formula of the lightweight high-strength aluminum-magnesium-copper high-entropy alloy of this example is Al 63 Mg 27 Cu 4.5 Zn 4.5 Si 1 , the preparation steps are as follows: the raw materials Al, Mg, Cu, Zn, Si with a purity greater than 99.9% are pressed by Al 63 Mg 27 Cu 4.5 Zn 4.5 Si 1 of ingredients to prepare 100g. Put the prepared raw materials into the graphite crucible in order of melting point from low to high, the element with the lowest melting point is placed at the bottom, and the element with the highest melting point is placed at the top. Put the graphite crucible filled with alloy materials into the spiral induction coil, evacuate to below 20Pa, and then fill with argon to 0.3MPa. Start the high-frequency induction device to control the induction heating current. After the alloy ingot melts, keep the alloy in a molten state for 30 minutes to make the alloy composition uniform. Cast the uniformly smelted alloy liquid into a steel...

Embodiment 3

[0027] The molecular formula of the lightweight high-strength aluminum-magnesium-copper high-entropy alloy of this example is Al 67.5 Mg 22.5 Cu 4.5 Zn 4.5 Si 1 , the preparation steps are as follows: the raw materials Al, Mg, Cu, Zn, Si with a purity greater than 99.9% are pressed by Al 67.5 Mg 22.5 Cu 4.5 Zn 4.5 Si 1 of ingredients to prepare 100g. Put the prepared raw materials into the graphite crucible in order of melting point from low to high, the element with the lowest melting point is placed at the bottom, and the element with the highest melting point is placed at the top. Put the graphite crucible filled with alloy materials into the spiral induction coil, evacuate to below 20Pa, and then fill with argon to 0.3MPa. Start the high-frequency induction device to control the induction heating current. After the alloy ingot melts, keep the alloy in a molten state for 30 minutes to make the alloy composition uniform. Cast the uniformly smelted alloy liquid into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com