Tubular high-voltage ceramic capacitor with umbrella skirt structures

A high-voltage ceramic and capacitor technology, applied in the field of capacitors, can solve the problems of capacitor failure, limited capacitance, short creepage distance, etc., to improve the withstand voltage performance and reliability, reduce the probability of breakdown, and increase the capacitance value of the capacitor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

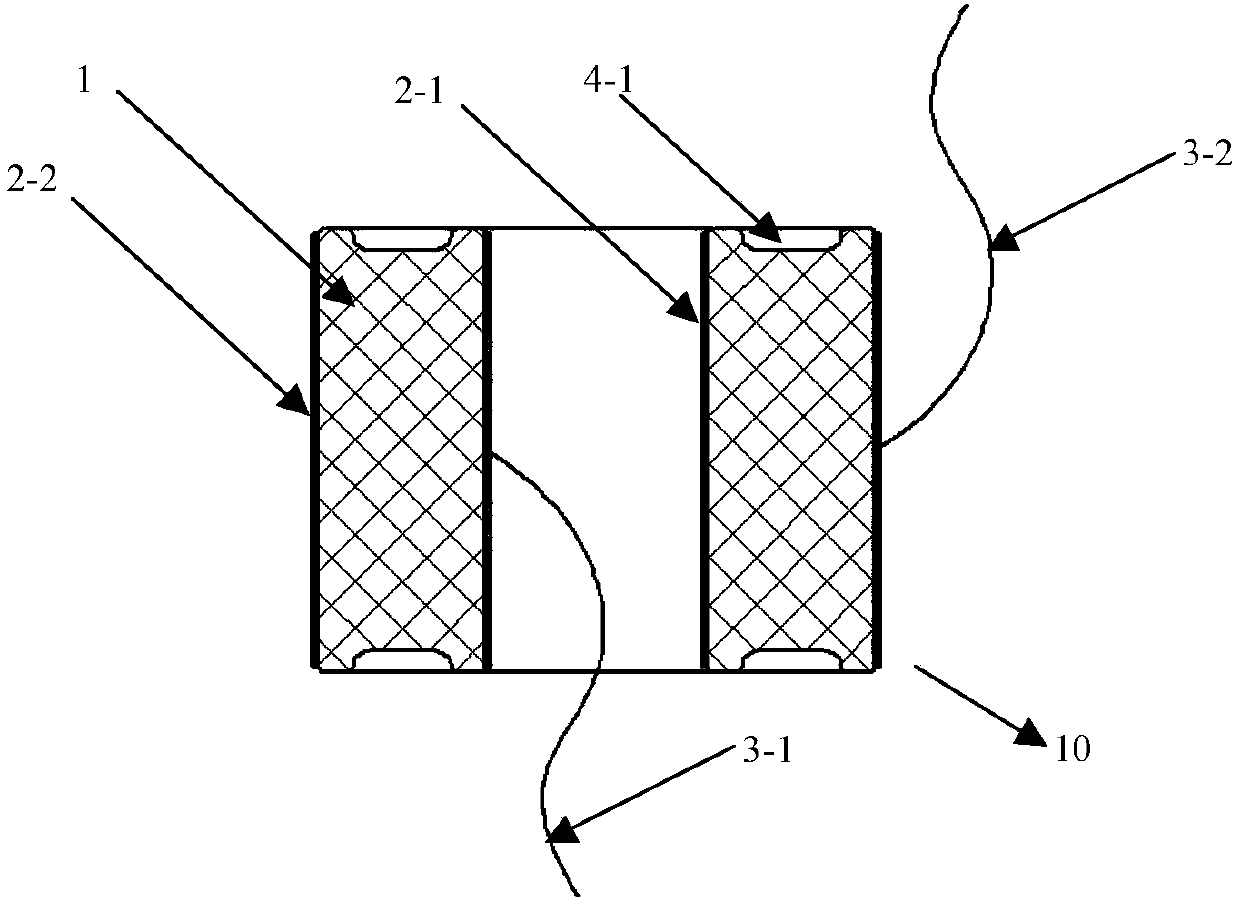

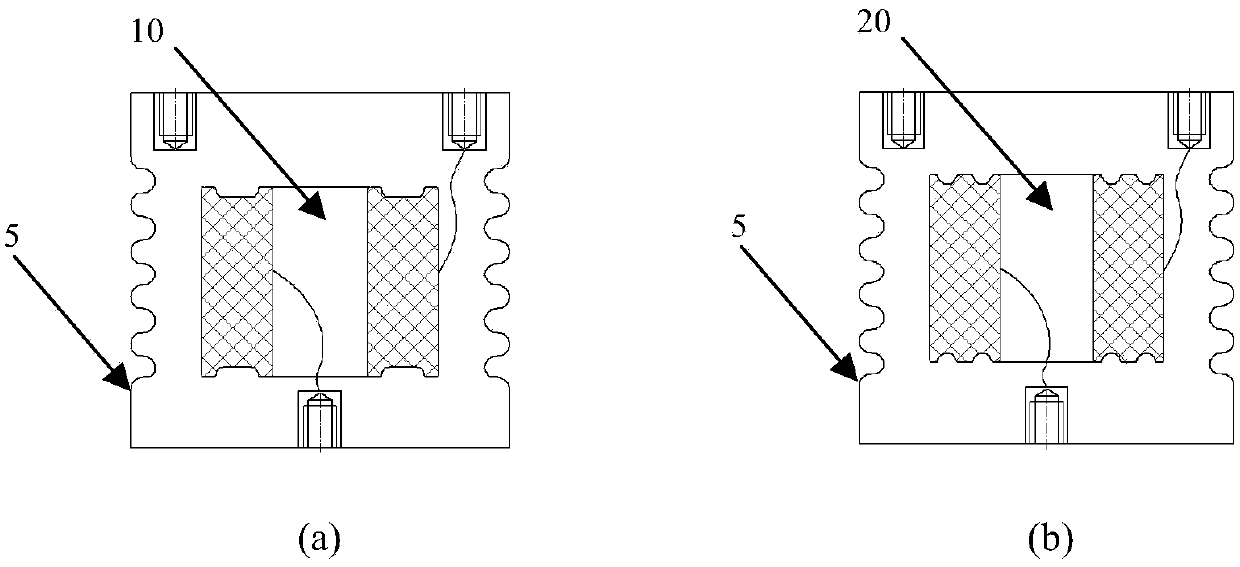

[0022] The structure of a tubular high-voltage ceramic capacitor 10 with an umbrella shed structure in this embodiment is as follows figure 1 As shown, it includes a high dielectric constant ceramic tube 1, which is prepared by pressing N4700 ceramic material with a dielectric constant of 2000 and high-temperature sintering process. The inner diameter of the ceramic tube is 30mm, the outer diameter is 60mm, and the height is 40mm; on the ceramic tube, The lower two ends are pressed once or reprocessed after forming (the specific processing method is a conventional process in this field) and the shed structure 4-1 is symmetrically provided. The shed structure is a circle of arc-shaped grooves, and the depth of the groove is 2mm The inner and outer surfaces of the ceramic tube are respectively wrapped with inner and outer silver electrode layers 2-1 and 2-2 (the thickness of the inner and outer silver electrode layers in this embodiment is 1-10 μm), and the electrode layer is for...

Embodiment 2

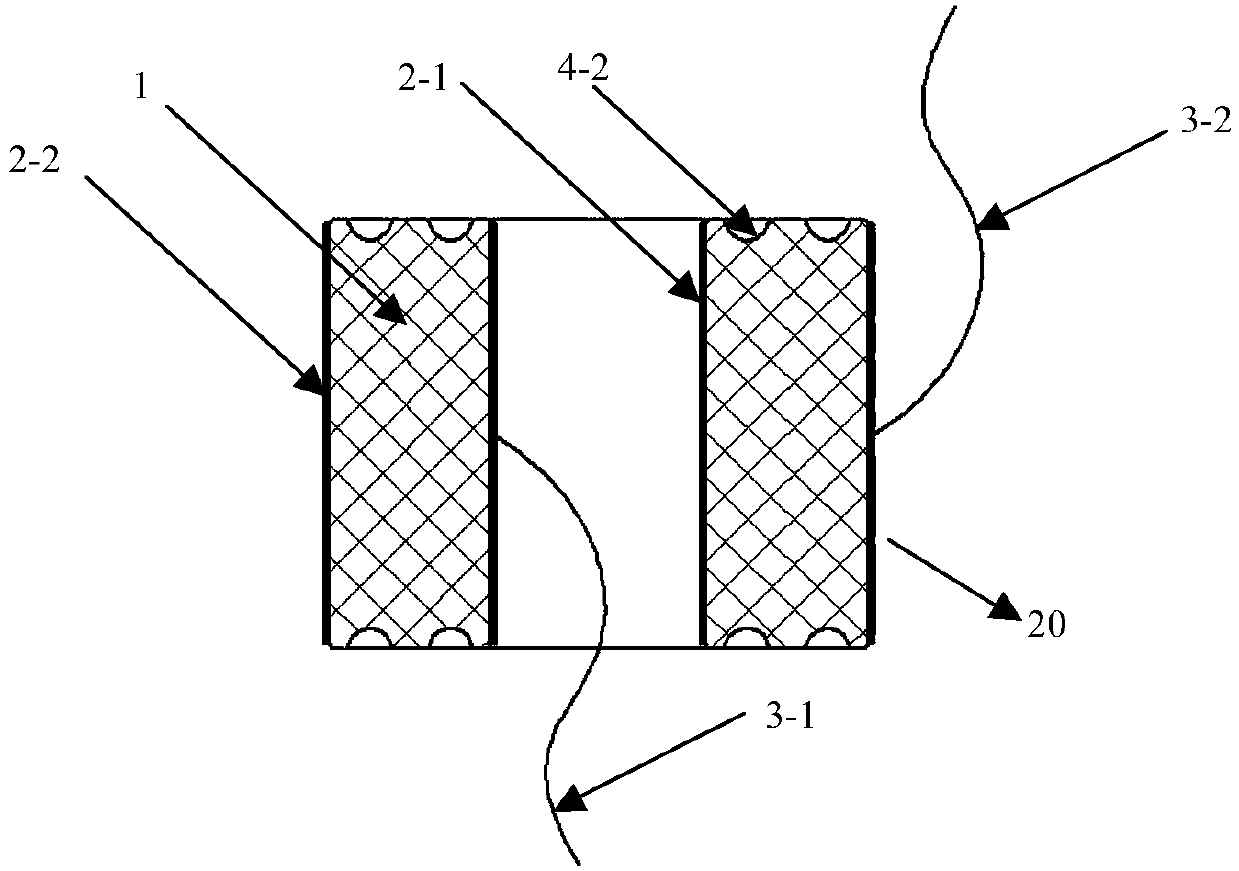

[0028] The structure of a tubular high-voltage ceramic capacitor 20 with an umbrella shed structure in this embodiment is as follows figure 2 As shown, this embodiment is roughly the same as Embodiment 1, except that the shed structure 4-2 of this embodiment is an inner and an outer circle of arc-shaped grooves, and the distance between the centers of the two circles of grooves is 6 mm. The groove depth is 2mm. Compared with Example 1, the shed structure adopted in this example can increase the creepage distance between the inner and outer electrode layers and further reduce the fringe electric field intensity. The capacitor of this embodiment is encapsulated by epoxy resin 5 through conventional encapsulation technology, and the structure after encapsulation is as follows image 3 (b) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com