Oxidation cleaning disinfector and preparation method thereof

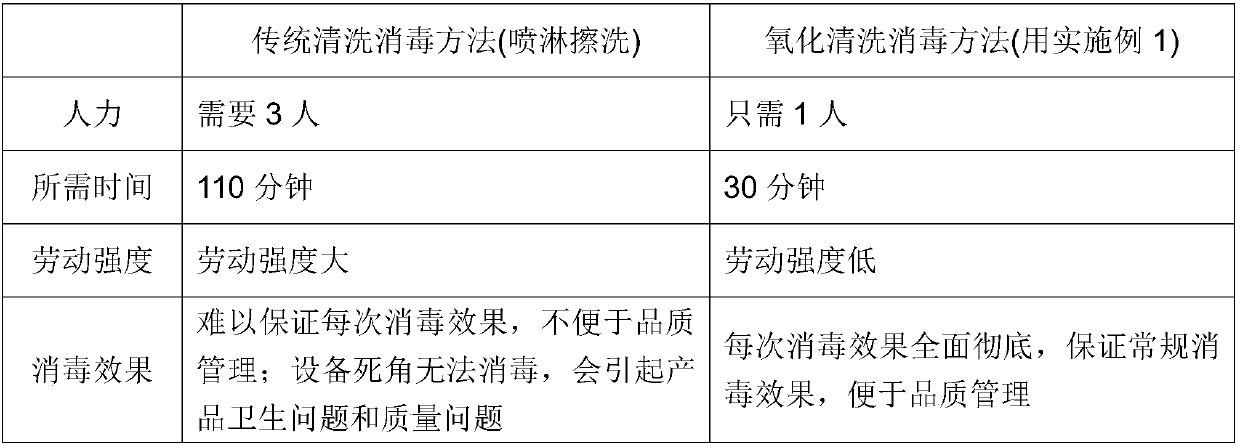

A disinfectant and peracetic acid technology, applied in the direction of disinfectant, chemical instruments and methods, botany equipment and methods, etc., can solve the problems of corrosion and bleaching, skin and mucous membrane irritation, strong sour smell, etc., and achieve bactericidal effect Reliable, strong penetrating bactericidal ability, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

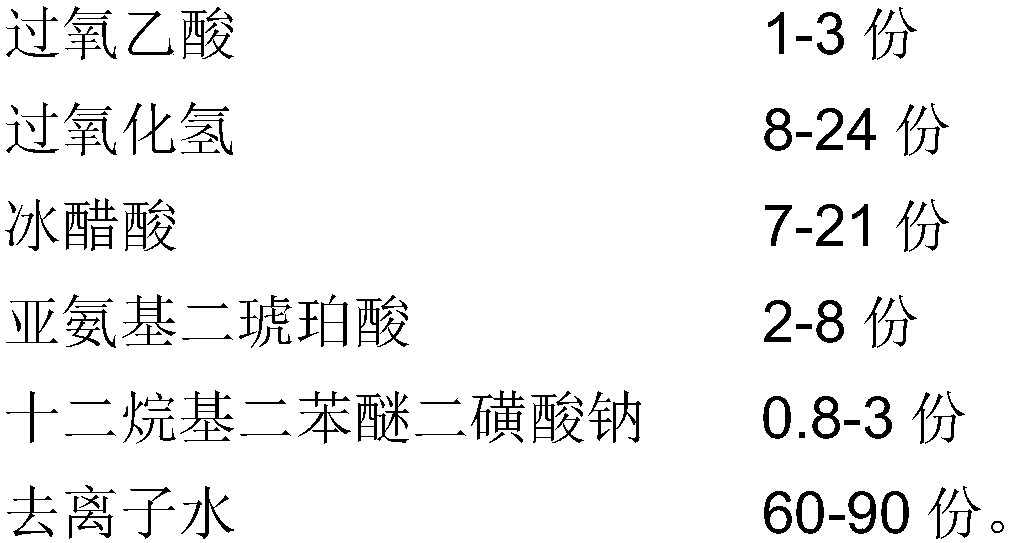

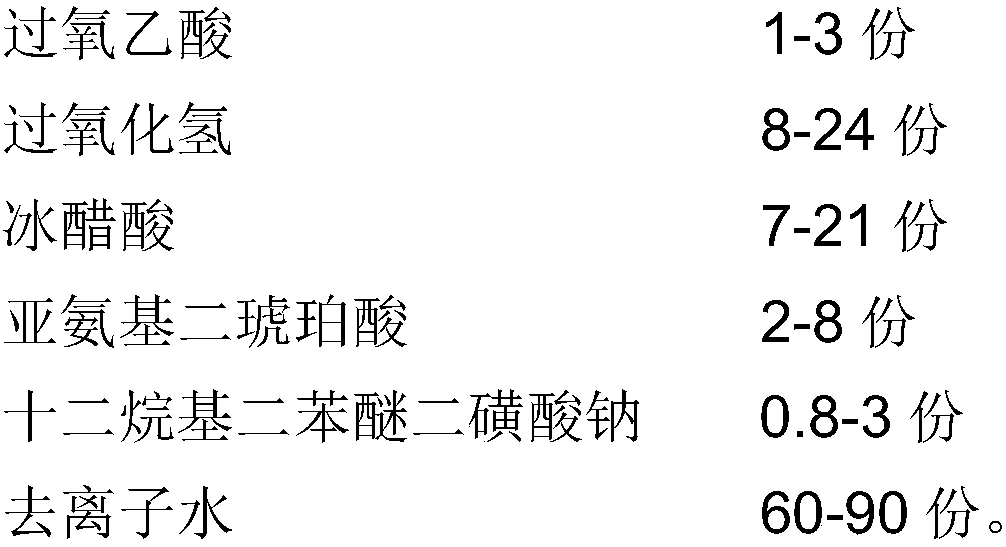

[0046] The invention provides a preparation method of an oxidative cleaning and disinfecting agent, the steps are as follows:

[0047] (1) Add 60-90 parts of deionized water to a clean reaction kettle and start stirring;

[0048] (2) Add 2-8 parts of iminodisuccinic acid and stir for 10-20 minutes at a speed of 400-800 rpm until it is completely dissolved.

[0049] (3) Under the rotation speed of 300-500 rpm, slowly add 8-24 parts of hydrogen peroxide, and stir for 10-20 minutes until completely mixed;

[0050] (4) At a speed of 300-500 rpm, slowly add 7-21 parts of glacial acetic acid, and stir for 10-20 minutes until fully mixed;

[0051] (5) At 300-500 rpm, slowly add 1-3 parts of peracetic acid, and stir for 10-20 minutes until completely mixed;

[0052] (6) At a speed of 200-400 rpm, slowly add 0.8-3 parts of sodium dodecyl diphenyl ether disulfonate, and stir for 10-20 minutes until completely mixed;

[0053] (7) Turn off the stirring to obtain a prepared oxidation cleaning and disi...

Embodiment 1

[0057] An oxidizing cleaning and disinfecting agent, the preparation method of the oxidizing cleaning and disinfecting agent is:

[0058] (1) Add 90 parts of deionized water to a clean reactor and start stirring;

[0059] (2) Add 8 parts of iminodisuccinic acid, and stir for 20 minutes at a speed of 800 rpm until it is completely dissolved.

[0060] (3) At a speed of 500 rpm, slowly add 24 parts of hydrogen peroxide, and stir for 20 minutes until fully mixed;

[0061] (4) At a speed of 500 rpm, slowly add 21 parts of glacial acetic acid, and stir for 20 minutes until completely mixed;

[0062] (5) At a speed of 500 rpm, slowly add 3 parts of peracetic acid, and stir for 20 minutes until fully mixed;

[0063] (6) At 400 rpm, slowly add 3 parts of sodium dodecyl diphenyl ether disulfonate, and stir for 20 minutes until completely mixed;

[0064] (7) Turn off the stirring to obtain a prepared oxidation cleaning and disinfectant;

[0065] (8) Filtering and discharging to obtain finished produc...

Embodiment 2

[0067] An oxidizing cleaning and disinfecting agent, the preparation method of the oxidizing cleaning and disinfecting agent is:

[0068] (1) Add 60 parts of deionized water to a clean reactor and start stirring;

[0069] (2) Add 2 parts of iminodisuccinic acid and stir for 10 minutes at a speed of 400 revolutions / minute until it is completely dissolved and uniform;

[0070] (3) At a speed of 300 rpm, slowly add 8 parts of hydrogen peroxide and stir for 10 minutes until completely mixed;

[0071] (4) At a speed of 300 rpm, slowly add 7 parts of glacial acetic acid, and stir for 10 minutes until fully mixed;

[0072] (5) At a speed of 300 rpm, slowly add 1 part of peracetic acid, and stir for 10 minutes until completely mixed;

[0073] (6) At a rotation speed of 200 rpm, slowly add 0.8 parts of sodium dodecyl diphenyl ether disulfonate, and stir for 10 minutes until completely mixed;

[0074] (7) Turn off the stirring to obtain a prepared oxidation cleaning and disinfectant;

[0075] (8) Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com