Method for disposing high-concentration ammonium sulfate waste water

An ammonium sulfate, high-concentration technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., to achieve the effects of reducing operating costs, low energy consumption, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

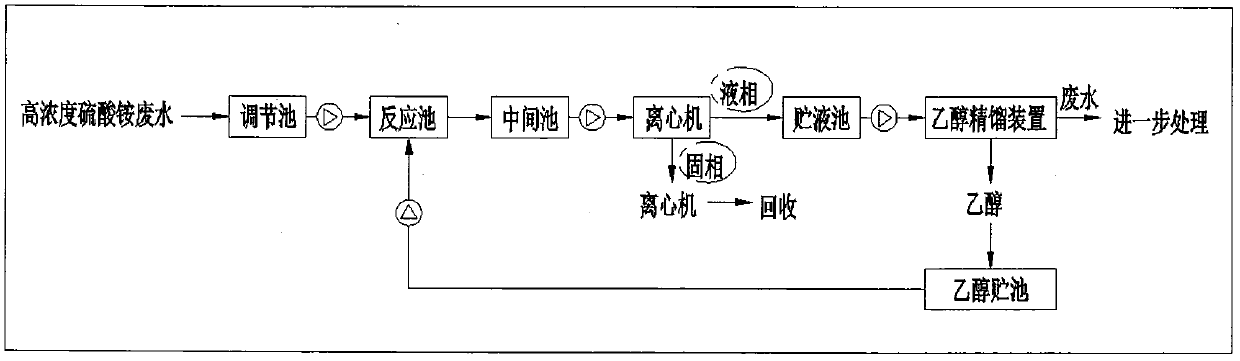

Method used

Image

Examples

Embodiment 1

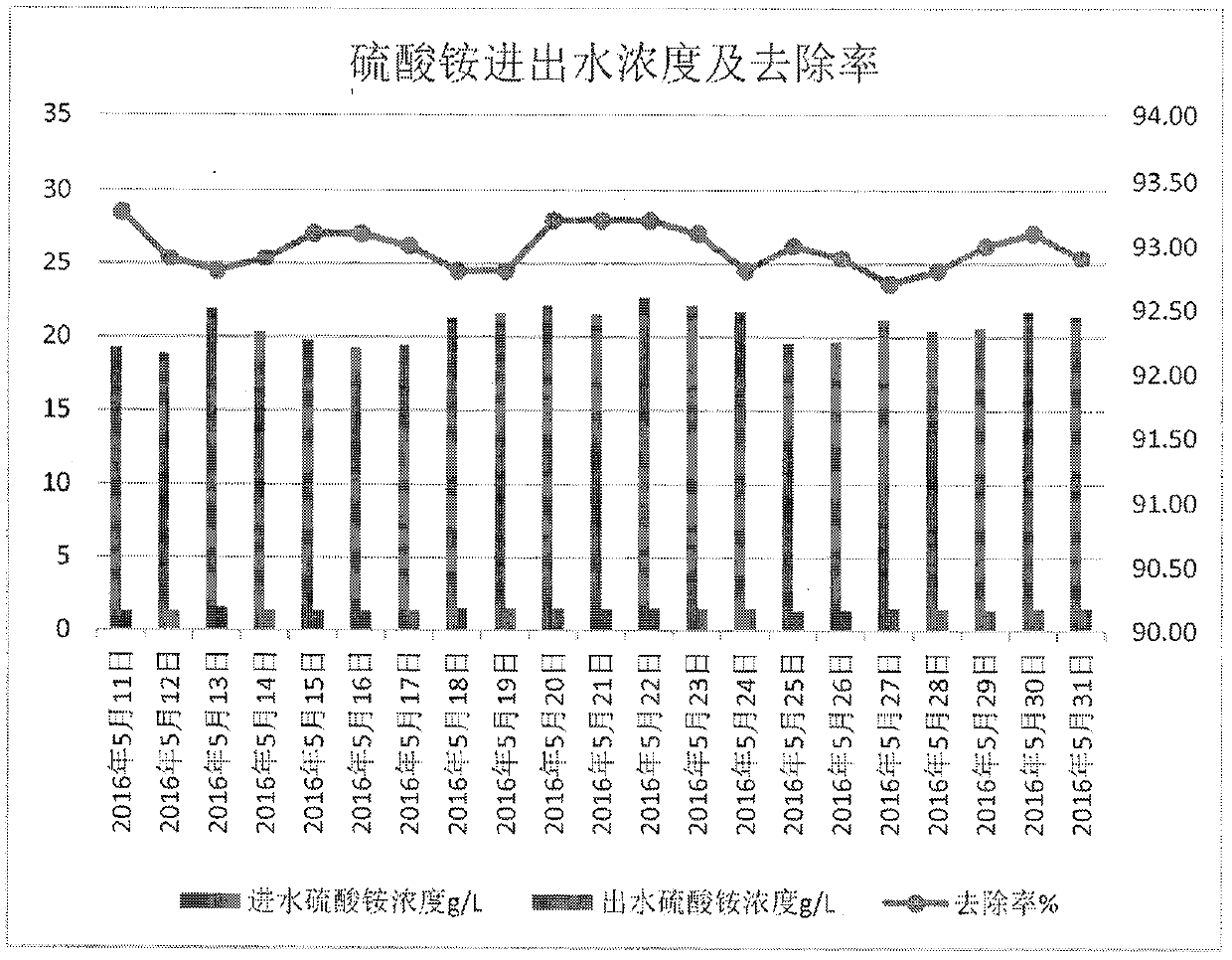

[0089] Embodiment 1 treats high-concentration ammonium sulfate wastewater discharged from a biopharmaceutical factory. The concentration of ammonium sulfate is about 20g / L, the COD is 4500mg / L~5000mg / L, and the discharge is 30t / d. The treatment facilities work 8 hours a day to complete the wastewater treatment work discharged on that day.

[0090] Follow the steps below to implement:

[0091] 1) Collect incoming water at different times into the regulating pool;

[0092] The high-concentration ammonium sulfate wastewater in the factory area can be collected separately, and the wastewater collected at different times is poured into the regulating pool, where a stainless steel underwater agitator is installed to ensure that the wastewater is evenly mixed. The capacity of the regulating pool can accommodate 5 days of drainage, leaving sufficient time for equipment maintenance and abnormal situations. A pump pit is arranged at the bottom of the regulating tank, and a submersible...

Embodiment 2

[0102] Example 2 A thioester antioxidant production enterprise, the discharged waste water contains part of free sulfuric acid, the mass fraction of free sulfuric acid is 32.3%, the concentration of ammonia nitrogen is 1.8mol / L, converted into ammonium sulfate concentration is about 34g / L , the water volume is 20t / d.

[0103] The treatment facility and treatment process are the same as in Example 1, but the whole process is continuous water inflow and continuous treatment, rather than sequential batch work.

[0104] 1) Collect incoming water at different times into the regulating pool;

[0105] The high-concentration ammonium sulfate wastewater in the factory area is collected separately and poured into the regulating pool. The stainless steel underwater agitator is installed in the regulating pool to ensure that the wastewater is evenly mixed. The capacity of the regulating pool can accommodate 3 days of drainage, leaving sufficient time for equipment maintenance and abnorma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com