Poultry manure collection and treatment method

A technology for feces collection and treatment, which is applied in the direction of sludge treatment, special treatment targets, biological sludge treatment, etc. It can solve the problems of long production cycle, no detailed classification of feces, and no need to pay too much attention to excreta, so as to achieve production High efficiency and improved fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

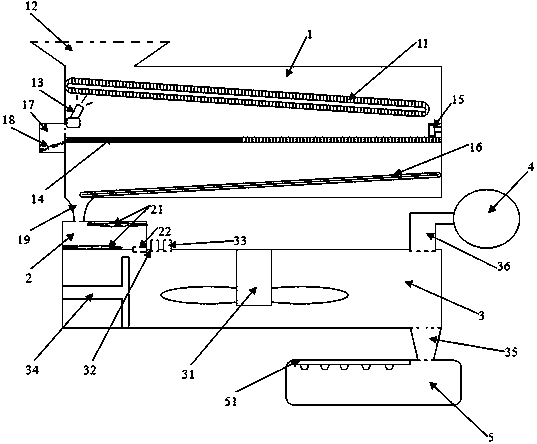

[0033] A method for collecting and treating poultry manure. The poultry manure collection and treatment method uses equipment for collecting and treating poultry manure, including a pretreatment chamber, a heating chamber, a reaction chamber, a biogas collection bag and an organic fertilizer treatment chamber.

[0034] The pretreatment chamber includes a pretreatment chamber shell, a feces inlet, a first conveyor belt, a main filter plate, a second conveyor belt, a high-pressure water nozzle, a filter plate push block, a sundry collection box and a pretreatment chamber outlet; the feces inlet is provided with On the left side of the top of the pretreatment chamber shell, there is a first conveyor belt under it. The first conveyor belt is arranged obliquely in a way that is high on the left and low on the right. A high-pressure water nozzle facing the first conveyor belt is provided, and a main filter plate is arranged laterally on the lower side of the first conveyor belt and t...

Embodiment 2

[0052] A method for collecting and treating poultry manure. The poultry manure collection and treatment method uses equipment for collecting and treating poultry manure, including a pretreatment chamber, a heating chamber, a reaction chamber, a biogas collection bag and an organic fertilizer treatment chamber.

[0053] The pretreatment chamber includes a pretreatment chamber shell, a feces inlet, a first conveyor belt, a main filter plate, a second conveyor belt, a high-pressure water nozzle, a filter plate push block, a sundry collection box and a pretreatment chamber outlet; the feces inlet is provided with On the left side of the top of the pretreatment chamber shell, there is a first conveyor belt under it. The first conveyor belt is arranged obliquely in a way that is high on the left and low on the right. A high-pressure water nozzle facing the first conveyor belt is provided, and a main filter plate is arranged laterally on the lower side of the first conveyor belt and t...

Embodiment 3

[0072] A method for collecting and treating poultry manure. The poultry manure collection and treatment method uses equipment for collecting and treating poultry manure, including a pretreatment chamber, a heating chamber, a reaction chamber, a biogas collection bag and an organic fertilizer treatment chamber.

[0073] The pretreatment chamber includes a pretreatment chamber shell, a feces inlet, a first conveyor belt, a main filter plate, a second conveyor belt, a high-pressure water nozzle, a filter plate push block, a sundry collection box and a pretreatment chamber outlet; the feces inlet is provided with On the left side of the top of the pretreatment chamber shell, there is a first conveyor belt under it. The first conveyor belt is arranged obliquely in a way that is high on the left and low on the right. A high-pressure water nozzle facing the first conveyor belt is provided, and a main filter plate is arranged laterally on the lower side of the first conveyor belt and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com