Synthetic ester lubricating oil base oil with high viscosity index and preparation method thereof

A lubricating oil base oil and synthetic ester technology, applied in the field of lubricating oil base oil, can solve problems such as high pour point and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

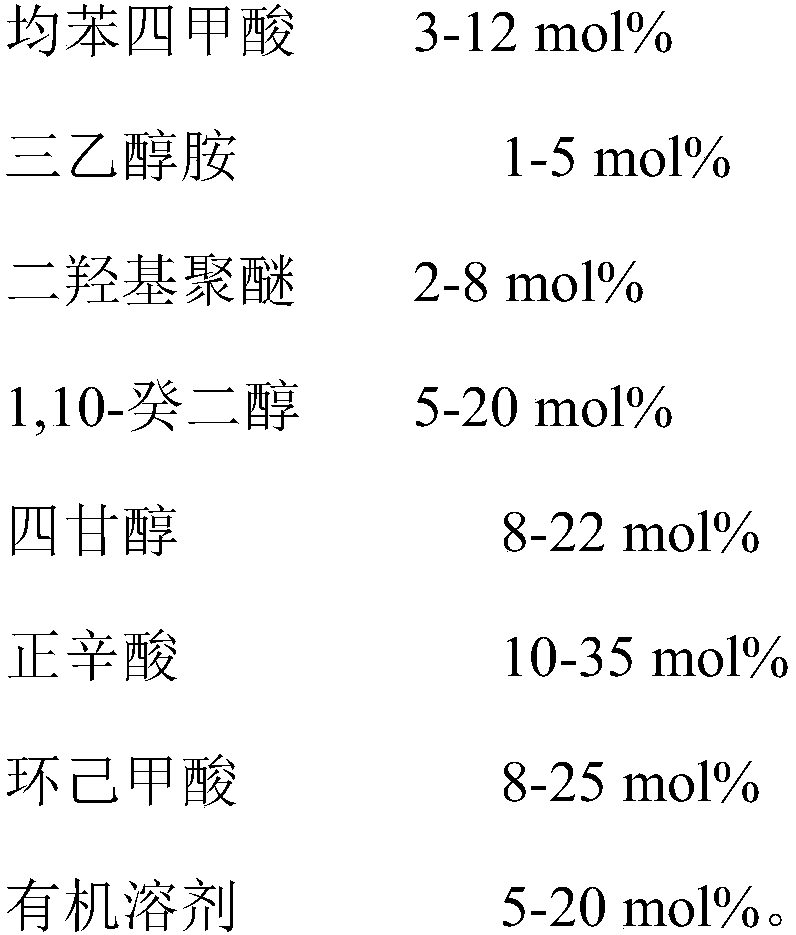

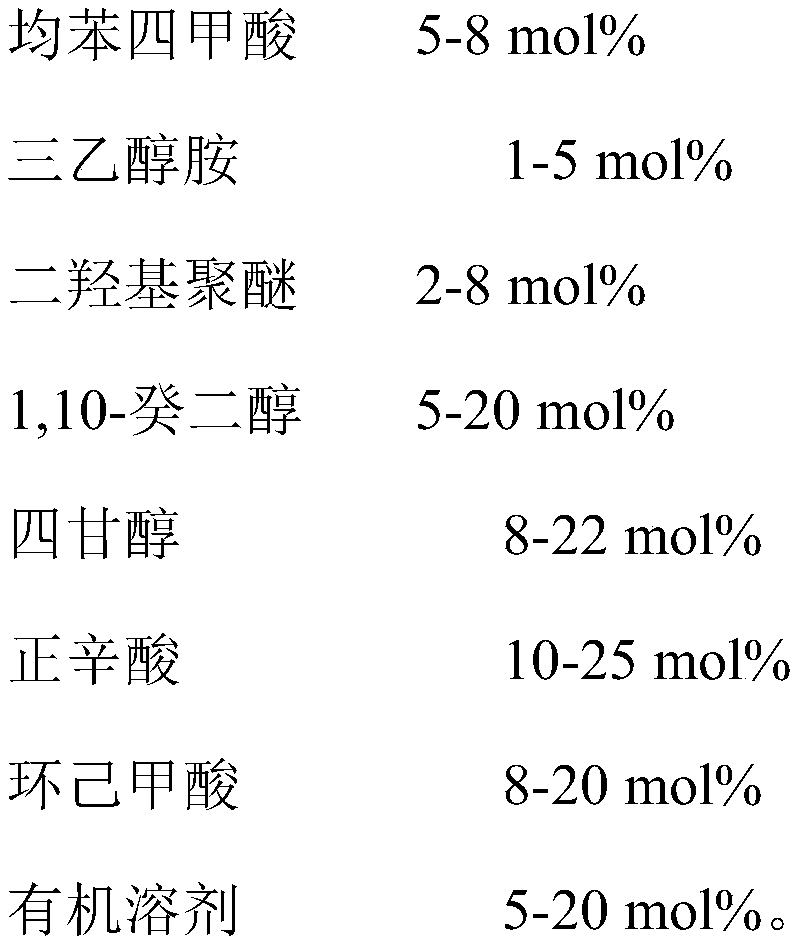

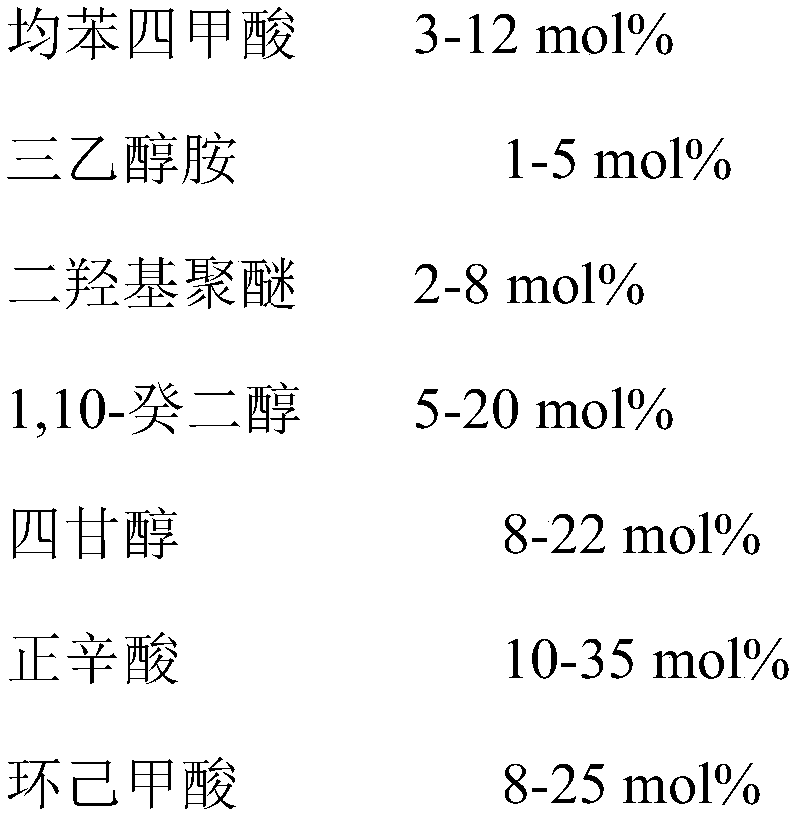

Method used

Image

Examples

Embodiment 1

[0048] A synthetic ester lubricant base oil with a high viscosity index, the main raw materials are 5mol of pyromellitic acid; 2mol of triethanolamine; 3mol of dihydroxy polyether; 20mol of 1,10-decanediol; 10mol of tetraethylene glycol; 20mol of n-octanoic acid; 20 mol of cyclohexanecarboxylic acid; 20 mol of xylene; 0.1 mol of monobutyl tin triisooctanoate, prepared by the following method:

[0049] (1) Add xylene, pyromellitic acid, triethanolamine, dihydroxy polyether, 1,10-decanediol, tetraethylene glycol, and catalyst into the reactor and mix them thoroughly, then heat to 140-150°C for dehydration and esterification reaction;

[0050] (2) Stop heating when the acid value is less than or equal to 4mgKOH / g, add n-octanoic acid and cyclohexanecarboxylic acid in step (1), and continue to heat up to 150-170°C for secondary esterification;

[0051] (3) When the acid value of the reaction mixture is reduced to ≤1mgKOH / g, the reaction is stopped, the xylene solvent and unreacte...

Embodiment 2

[0055] A synthetic ester lubricant base oil with a high viscosity index, the main raw materials are 12mol of pyromellitic acid; 5mol of triethanolamine; 8mol of dihydroxy polyether; 5mol of 1,10-decanediol; 22mol of tetraethylene glycol; 35mol of n-octanoic acid; 8 mol of cyclohexanecarboxylic acid; 5 mol of xylene; 0.5 mol of monobutyl tin triisooctanoate, prepared by the following method:

[0056] (1) Add xylene, pyromellitic acid, triethanolamine, dihydroxy polyether, 1,10-decanediol, tetraethylene glycol, and catalyst into the reactor and mix them thoroughly, then heat to 140-150°C for dehydration and esterification reaction;

[0057] (2) Stop heating when the acid value is less than or equal to 4mgKOH / g, add n-octanoic acid and cyclohexanecarboxylic acid in step (1), and continue to heat up to 150-170°C for secondary esterification;

[0058] (3) When the acid value of the reaction mixture is reduced to ≤1mgKOH / g, the reaction is stopped, the xylene solvent and unreacted ...

Embodiment 3

[0062] A synthetic ester lubricant base oil with a high viscosity index, the main raw materials are 3mol of pyromellitic acid; 3mol of triethanolamine; 6mol of dihydroxy polyether; 16mol of 1,10-decanediol; 20mol of tetraethylene glycol; 12mol of n-octanoic acid; 25 mol of cyclohexanecarboxylic acid; 15 mol of toluene; 0.2 mol of monobutyl tin triisooctanoate, prepared by the following method:

[0063] (1) Add toluene, pyromellitic acid, triethanolamine, dihydroxy polyether, 1,10-decanediol, tetraethylene glycol, and catalyst into the reactor and mix them thoroughly, then heat to 140-150°C for dehydration esterification reaction ;

[0064] (2) Stop heating when the acid value is less than or equal to 4mgKOH / g, add n-octanoic acid and cyclohexanecarboxylic acid in step (1), and continue to heat up to 150-170°C for secondary esterification;

[0065] (3) When the acid value of the reaction mixture is reduced to ≤1mgKOH / g, the reaction is stopped, the toluene solvent and unreacte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com