Ultrathin high-performance protection element and production method

A protection component, high-performance technology, applied in electrical components, emergency protection devices, circuits, etc., can solve problems such as difficulty in improving breaking capacity, poor fuse consistency, and inability to accurately fuse, saving carrier space, accurate fuse efficiency, The effect of protection from contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

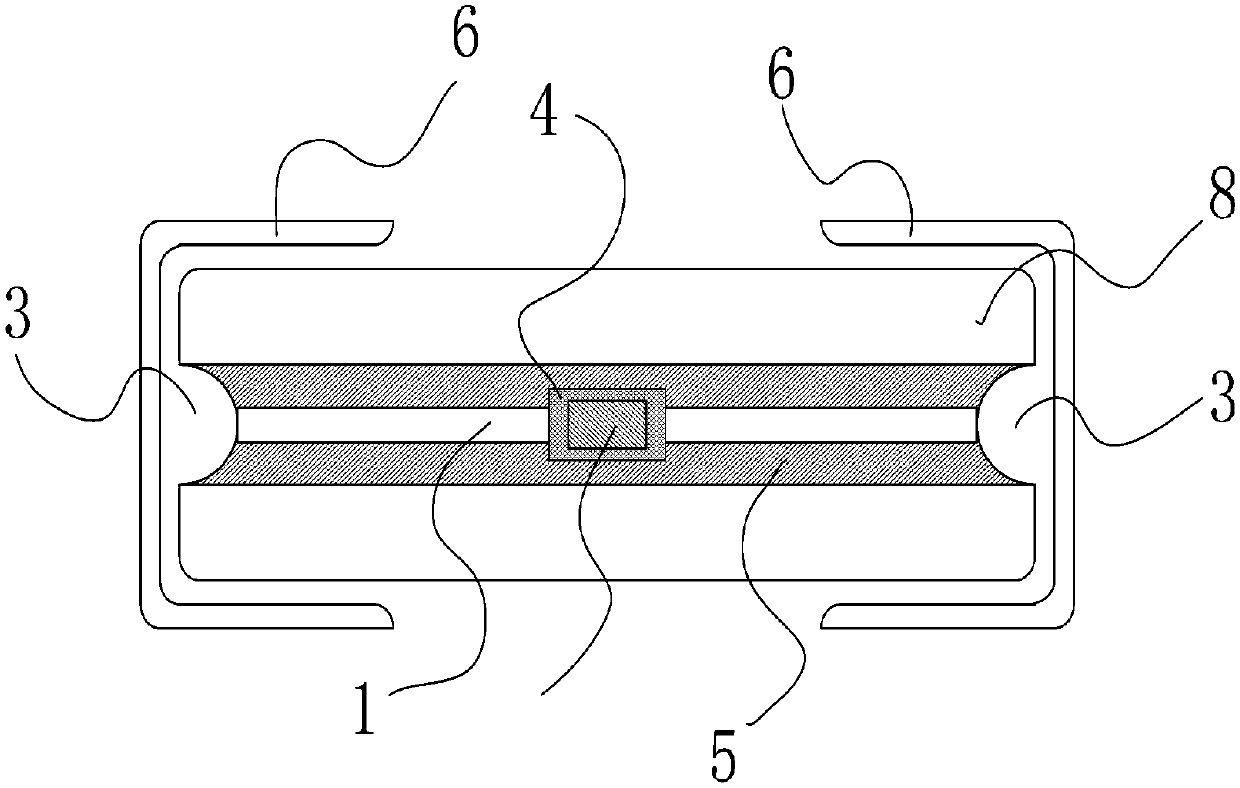

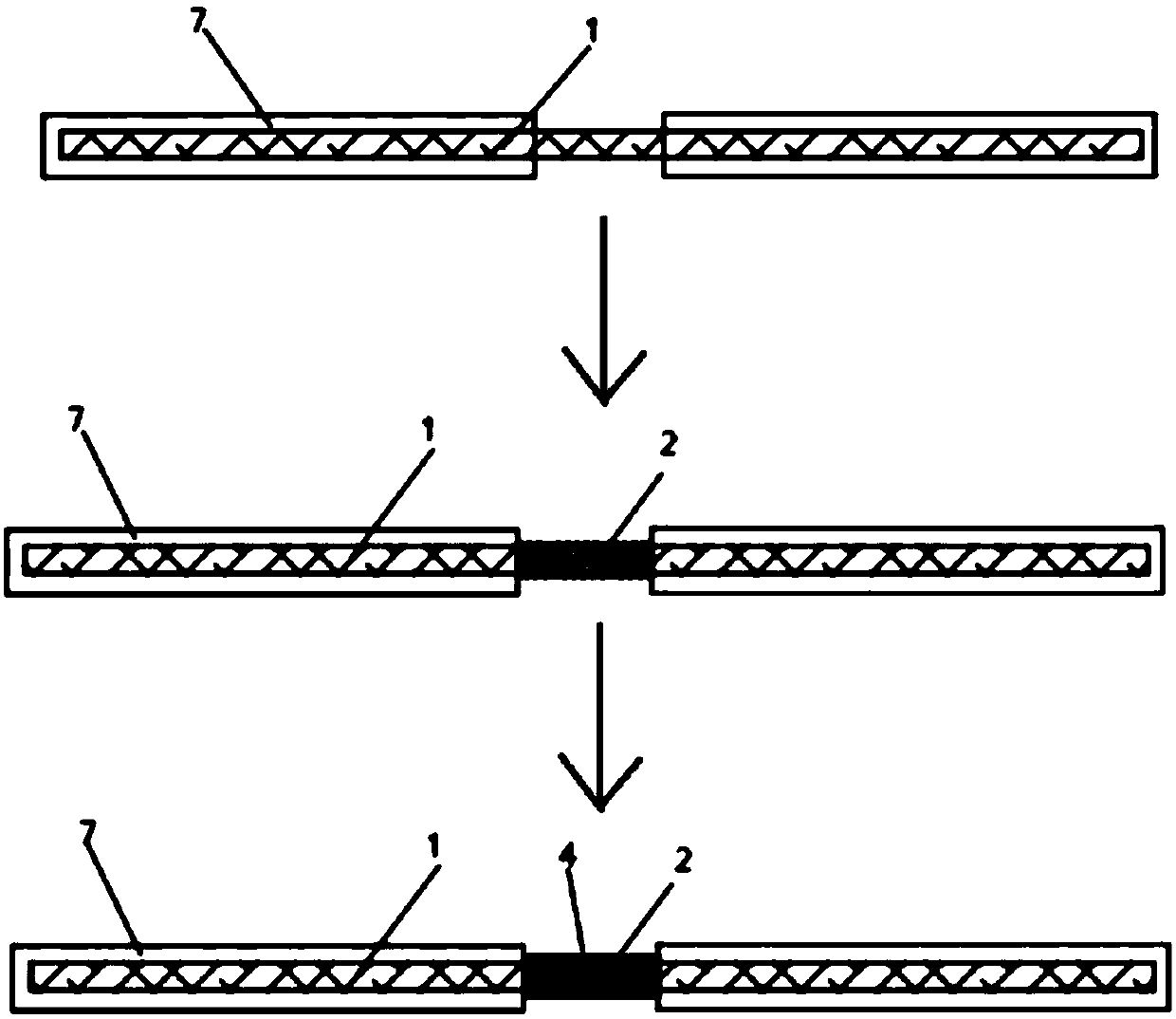

[0031] An ultra-thin anti-lightning protection component, such as figure 1 As shown, it includes a melt 1 and internal electrodes 3 arranged on both sides of the melt 1, a flux 2 wrapping the middle part of the melt 1, a wrapping layer 4 wrapping the outer layer of the flux 2, and two outer sides of the wrapping layer 8. The end is also provided with an external electrode 6, the external electrode 6 extends out of the encapsulation layer, and the melt 1 and the internal electrode 3, and the internal electrode 3 and the external electrode 6 form an electrical connection. An arc extinguishing material 5 may also be arranged inside the encapsulation layer 8 .

[0032] The melt 1 can be a combination or alloy of common metals such as silver, copper, tin, etc. In this embodiment, the melt 1 is a metal fuse, which can be linear, curved or spring-shaped, and the inner electrode is a solder ball. Extremely metal cap; encapsulation layer 8 is generally a ceramic tube, a plastic tube, ...

Embodiment 2

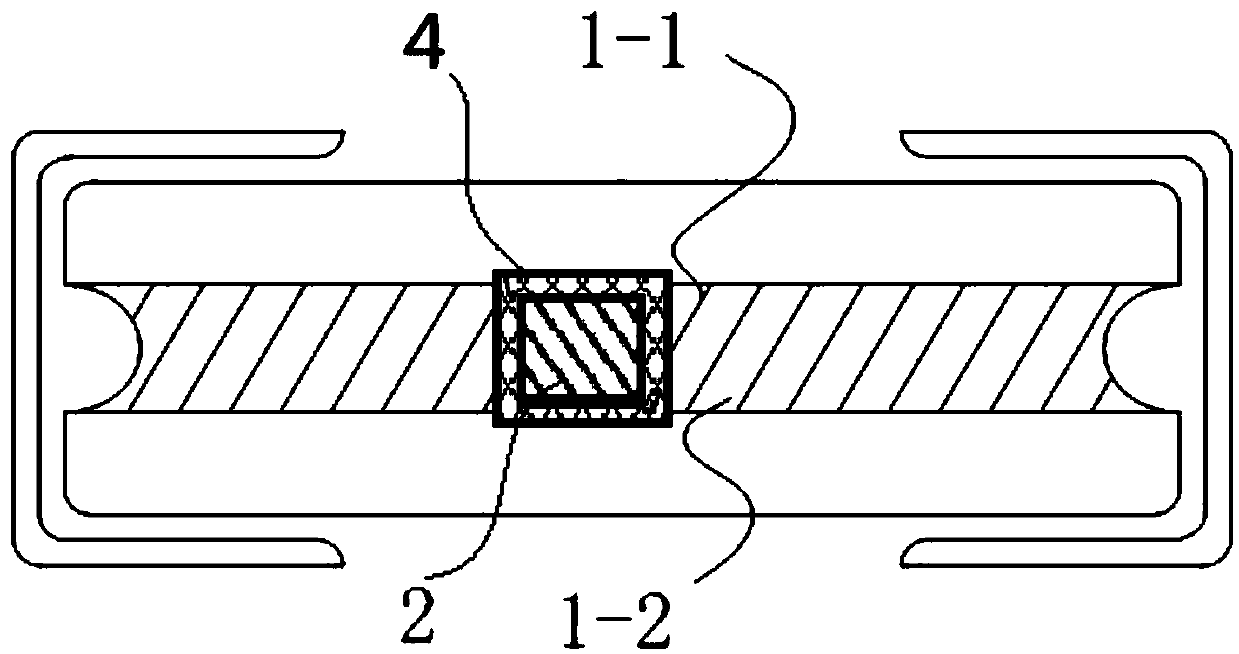

[0043] combine image 3 with Figure 4 , an ultra-thin high-performance protective element, including a melt 1 and internal electrodes 3 arranged on both sides of the melt 1, a flux 2 arranged in the middle part of the melt 1, a wrapping layer 4 wrapping the flux 2, and External electrodes 6 are also provided at both ends of the outer side of the sealing layer 8 , and the outer electrodes 6 protrude out of the sealing layer to form electrical connections between the melt 1 and the inner electrodes 3 , and between the inner electrodes 3 and the outer electrodes 6 .

[0044] In this embodiment, the encapsulation layer 8 is an ultra-thin porcelain tube with a rectangular cross-sectional shape and an elliptical inner cavity. The melt 1 is composed of a metal fuse 1-1 wound on a carrier 1-2. In order to adapt to the encapsulation layer 8 In the ultra-thin space of the inner cavity, the carrier 2 is a flat carrier with a certain width and a certain rigidity, and the flux 2 and the ...

Embodiment 3

[0056] combine Image 6 , an ultra-thin high-performance protective element. The difference from the second embodiment is that the carrier 1-2 is made of materials such as polymers that can be softened by heating. In step S201, the metal fuse 1-1 is wound by a wire winding machine In the carrier 1-2 (the carrier 2 at this time can be in the shape of a cylinder, a square column, etc.), the melt 1 is heated as a whole after this step, wherein the carrier 1-2 is softened, and the whole melt 1 is flattened to the required For example, in this embodiment, the melt 1 can be pressed to the required height, and the metal fuse 1-1 is partially sunk into the carrier 1-2, forming an inset on the carrier 1-2 that fits the shape of the fuse Structure 9, the recessed structure 9 is in the shape of a circular arc groove, the metal fuse 1-1 is wound in the recessed structure 9 of the metal fuse of the carrier 1-2, and the metal fuse 1-1 is between the upper and lower two No contact, no short...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com