A method for increasing the concentration efficiency and the spray drying yield of a myrrh extract liquid

A kind of medicine extracting liquid and technology of extracting liquid, applied in the direction of medical formula, non-active ingredient medical preparation, medical preparation containing active ingredient, etc., can solve the problems of reducing concentration efficiency, reducing active ingredient, reducing spray yield, etc. , to achieve the effect of improving concentration efficiency, reducing material loss and reducing concentration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

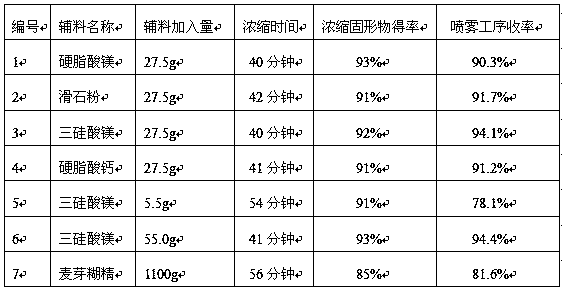

Examples

Embodiment 1

[0017] Take the decoction pieces of myrrh and put them into a multifunctional extraction tank, add water to decoct twice, combine the decoction, take 500 kg of myrrh extract, the solid content (that is, the dry extract content) is 1.1%, add magnesium stearate 27.5 g (accounting for 0.5% of the solid content), mix evenly, concentrate, and then spray dry. The air inlet temperature is controlled at 150°C, and the outlet air temperature is controlled at 60~70°C. Collect the extract powder and dry granulate, that is have to.

Embodiment 2

[0019] Take 500 kg of myrrh extract, the solid content (that is, dry extract content) is 1.1%, add 27.5g of talcum powder (accounting for 0.5% of the solid content), mix well, then concentrate, then spray dry, The air temperature is controlled at 160°C, the outlet air temperature is controlled at 70-80°C, the extract powder is collected, and dry granulated to obtain the product.

Embodiment 3

[0021] Take 500 kg of myrrh extract, the solid content (that is, the dry extract content) is 1.1%, add 27.5g of magnesium trisilicate (accounting for 0.5% of the solid content), mix well, then concentrate, and then spray dry , the inlet air temperature is controlled at 150°C, the outlet air temperature is controlled at 60-70°C, the extract powder is collected, and dry granulated to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com