CAD/CAM engravable lithium disilicate microcrystalline glass for dentistry and preparation method thereof

A technology of glass-ceramics and lithium disilicate, which is applied in the field of glass-ceramics and can solve problems such as low fracture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

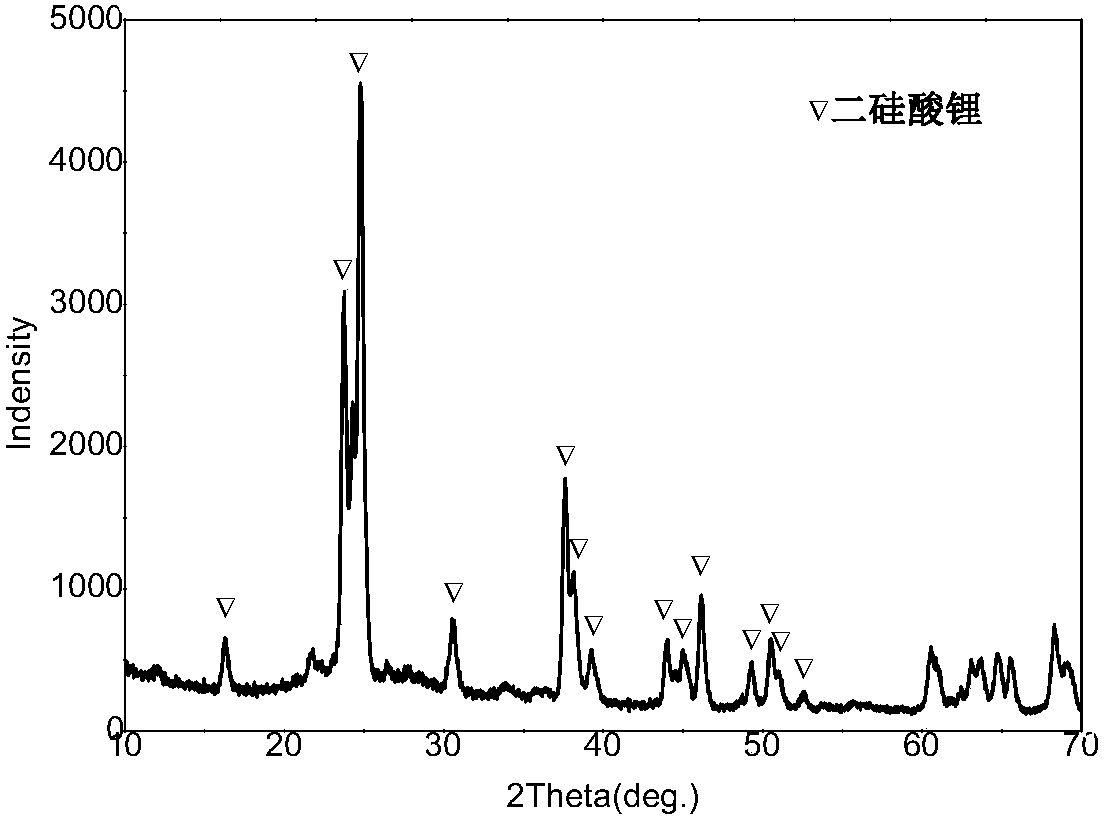

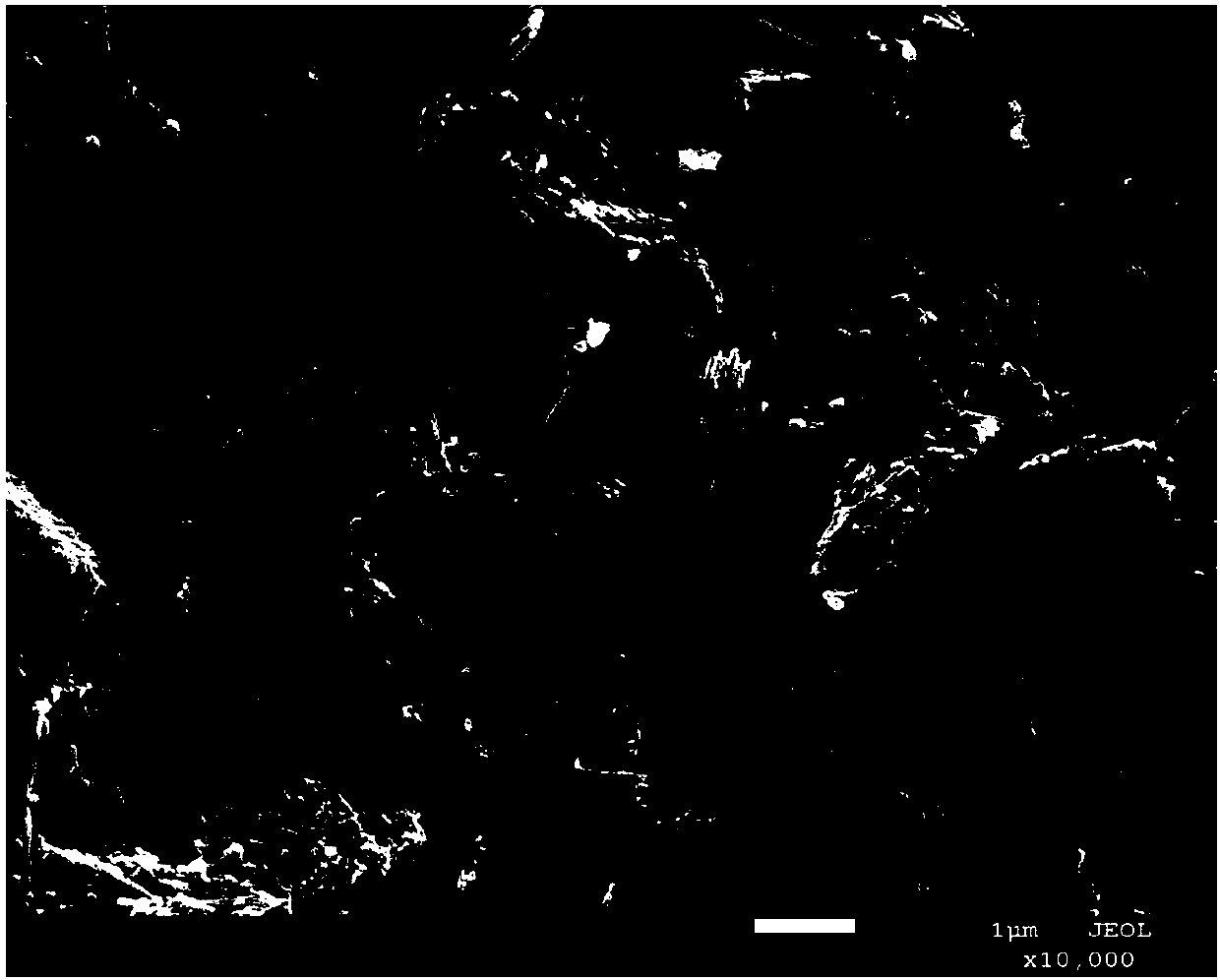

[0108] Introducing Rb into the glass formulation 2 O, the main crystal phase of the product is lithium disilicate, and the secondary crystal phase is lithium silicate and lithium phosphate glass-ceramics. The specific preparation steps are as follows:

[0109] 1. Design its basic chemical composition

[0110] SiO 2 : 70%, Li 2 O: 14.6%, Rb 2 O: 6.2%, Al 2 o 3 : 1.94%, P 2 o 5 : 2.72%, ZnO: 1.5%; CeO 2 : 1%, Tb 4 o 7 : 0.3%, MgO: 1%, La 2 o 3 : 0.5%, TiO 2 : 0.24%.

[0111] 2. Material selection

[0112] Use chemically pure or industrially pure drugs for melting, where Rb 2 O was introduced using rubidium carbonate, SiO 2 Introduced using silica powder, Li 2 O was introduced using lithium carbonate, Al 2 o 3 Use aluminum hydroxide to introduce, ZnO to use zinc oxide to introduce, CeO 2 Introduced using cerium oxide, Tb 4 o 7 Terbium heptoxide was introduced, MgO was introduced using magnesium carbonate, La 2 o 3 Introduced using lanthanum oxide, TiO 2 I...

Embodiment 2

[0127] Introducing Rb into the glass formulation 2 O, the main crystal phase of the product is lithium disilicate, and the secondary crystal phase is lithium silicate and lithium phosphate glass-ceramics. The specific preparation steps are as follows:

[0128] 1. Design its basic chemical composition

[0129] SiO 2 : 70%, Li 2 O: 14.6%, Rb 2 O: 5%, Al 2 o 3 : 1.55%, P 2 o 5 : 2.75%, ZnO: 3%, CeO 2 : 1%, Tb 4 o 7 : 0.4%, MgO: 0.5%, La 2 o 3 : 0.5%, TiO 2 : 0.7%.

[0130] 2. Material selection

[0131] Use chemically pure or industrially pure drugs for melting, where Rb 2 O was introduced using rubidium carbonate.

[0132] 3. Ingredients

[0133] Do the ingredients according to the above ingredient list, accurately calculate the required ingredients and carry out the ingredients. After the ingredients are fully ball milled to ensure that the raw materials are mixed evenly.

[0134] 4. Pre-burning

[0135] The prepared raw materials were pre-fired in a muffle fur...

Embodiment 3

[0146] Introducing Rb into the glass formulation 2 O, the main crystal phase of the product is lithium disilicate, and the secondary crystal phase is glass-ceramics of lithium silicate and lithium phosphate. The specific preparation steps are as follows:

[0147] 1. Design its basic chemical composition

[0148] SiO 2 : 70.7%, Li 2 O: 14.34%, Rb 2 O: 6.1%, Al 2 o 3 : 1.92%, P 2 o 5 : 2.73%, CeO 2 : 1%, Tb 4 o 7 : 0.21%, MgO: 2%, La 2 o 3 : 0.5%, TiO 2 : 0.5%.

[0149] 2. Material selection

[0150] Use chemically pure or industrially pure drugs for melting, where Rb 2 O was introduced using rubidium carbonate.

[0151] 3. Ingredients

[0152] Do the ingredients according to the above ingredient list, accurately calculate the required ingredients and carry out the ingredients. After the ingredients are fully ball milled to ensure that the raw materials are mixed evenly.

[0153] 4. Pre-burning

[0154] The prepared raw materials were pre-fired in a muffle fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com