Method for preparing dimethyl sulfoxide from dimethyl sulfide

A technology of dimethyl sulfide and dimethyl sulfoxide, which is applied in the chemical industry and can solve problems such as hidden dangers and safety in gas-phase oxidation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

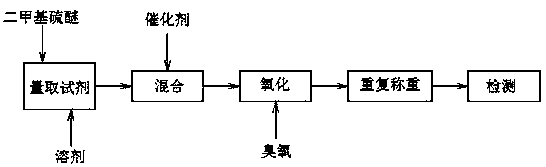

Method used

Image

Examples

Embodiment 1

[0023] In this example, reagents were weighed to prepare a mixed solution with a mass ratio of dimethyl sulfide: dimethyl sulfoxide: catalyst of 1:4:0.01. at 0.12m 3 The flow rate of / h is passed into ozone, and the ozone concentration is controlled at 0.075 kg / m 3 above. Keep the reaction temperature at 5°C and continue the reaction for 30 min. Detection and calculation: the conversion rate of dimethyl sulfide is 92.51%, and the yield is 94.25%.

Embodiment 2

[0025] In this example, reagents were weighed to prepare a mixed solution with a mass ratio of dimethyl sulfide: dimethyl sulfoxide: catalyst of 1:4:0.05. at 0.12m 3 Ozone is fed at a flow rate of / h, and the ozone concentration is controlled above 0.075 kg / m3. Keep the reaction temperature at 5°C and continue the reaction for 30 min. Detection and calculation: the conversion rate of dimethyl sulfide is 98.94%, and the yield is 96.03%.

Embodiment 3

[0027] In this embodiment, reagents were weighed to prepare a mixed solution with a mass ratio of dimethyl sulfide: dimethyl sulfoxide: catalyst of 1:1.5:0.05. at 0.18m 3 The flow rate of / h is passed into ozone, and the ozone concentration is controlled at 0.075 kg / m 3 above. Keep the reaction temperature at 5°C and continue the reaction for 30 min. Detection and calculation: the conversion rate of dimethyl sulfide is 85.91%, and the yield is 90.77%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com