Novel hydraulic clamp oil source

A technology of hydraulic fixture and hydraulic oil, applied in the field of hydraulic fixture oil source, can solve the problems of reducing the service life of hydraulic oil and energy, affecting test efficiency and result accuracy, waste and other problems, so as to achieve the effect of not producing energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

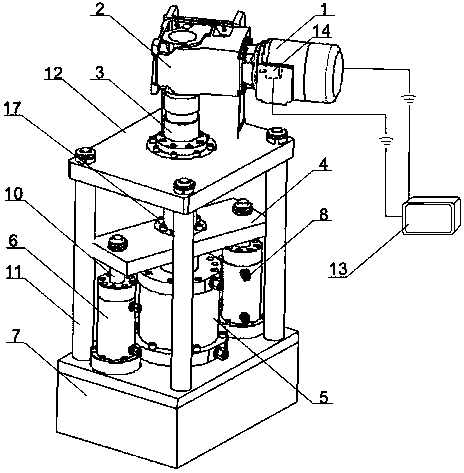

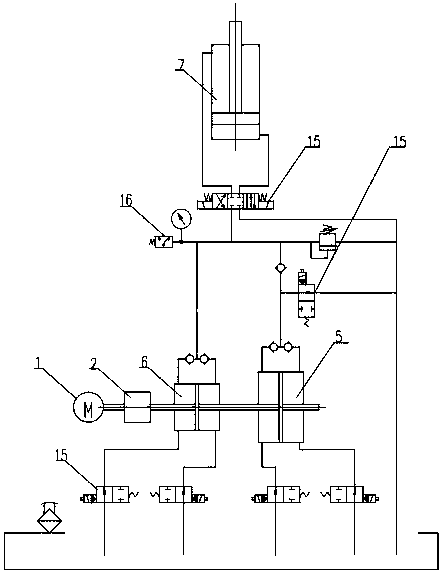

[0036] Such as figure 1 , 2 As shown, a new type of hydraulic clamp oil source described in the embodiment of the present invention includes a servo motor 1, a reducer 2, a screw 3, a connecting plate 4, a fast feed cylinder 5, a work feed cylinder 6, an oil tank 7, an induction Switch 8, support column 11, support plate 12, motion controller 13, photoelectric encoder 14, reversing valve 15, pressure sensor 16, screw nut 17;

[0037] The oil tank 7 is arranged at the bottom of the whole device, and hydraulic oil is stored in it to provide oil source for the hydraulic fixture; fast-forward oil cylinder 5 and work-feed oil cylinder 6 are installed above the oil tank 7; fast-forward oil cylinder 5 and work-feed oil cylinder 6 are located above it Supporting columns 11 are arranged externally;

[0038] A support plate 12 is fixed above the support column 11 for supporting the reducer 2, and a screw hole is arranged in the middle of the support plate 12;

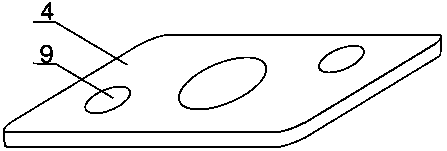

[0039] A connection pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com