A steam-water flushing method for a high-temperature-resistant solid-state heat storage system

A heat storage system and high temperature resistant technology, which is applied in solar heating systems, solar heat storage, solar thermal energy, etc., can solve problems affecting the normal use of heat storage towers, concrete cracking, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

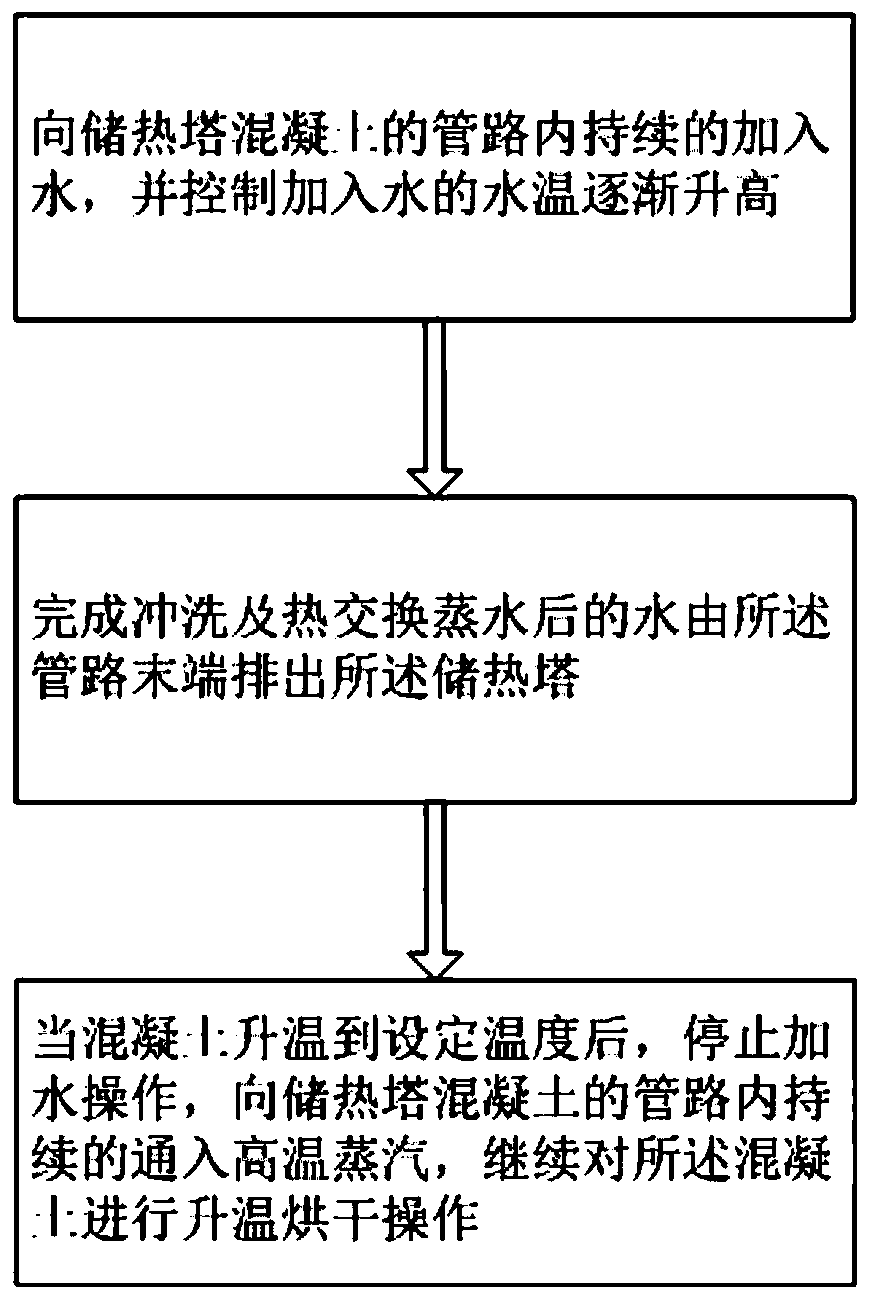

[0034] Example as figure 1 As shown, a method for flushing a high-temperature-resistant solid-state heat storage system with distilled water includes the following steps:

[0035] Continuously add water to the concrete pipeline of the heat storage tower, and control the water temperature of the added water to gradually increase, so as to realize the synchronous flushing of the pipeline and the steaming of the concrete heat exchange;

[0036] After flushing and heat exchange, the distilled water is discharged from the heat storage tower at the end of the pipeline;

[0037] When the temperature of the concrete reaches the set temperature, the water addition operation is stopped, and the high-temperature steam is continuously fed into the concrete pipeline of the heat storage tower, and the temperature-raising and drying operation of the concrete is continued.

[0038] The temperature of the concrete is raised to the set temperature after the temperature of the concrete in the l...

Embodiment 2

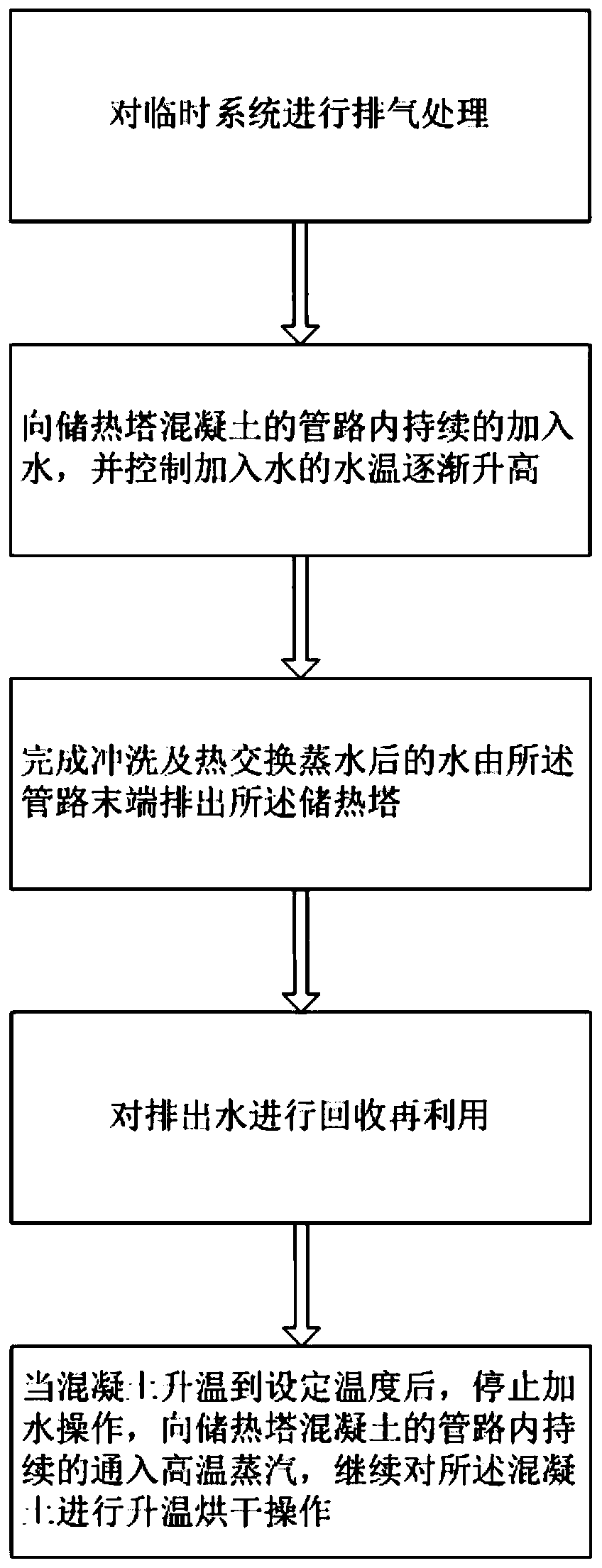

[0043] Example two such as figure 2 As shown, for the water and steam added to the concrete pipeline, external equipment can be used to provide continuously heated water and steam, or the existing structure of the power station can be used to provide continuously heated water and steam.

[0044] Specifically, build a temporary system, the temporary system includes a high-pressure heat exchanger, and the high-pressure heat exchanger is connected to the heat collecting circulating water pump and steam output pipeline of the power station through a temporary pipeline;

[0045] Use the water in the heat collection circulating water tank of the power station and the steam generated by the Sun Island of the power station to exchange heat in the high-pressure heat exchanger of the temporary system, and the high-pressure heat exchanger adds high-temperature water after heat exchange to the upper concrete pipe of the heat storage tower .

[0046] The heat collecting circulating water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com