Double-circulation cooling unit for sintering machine and cooling device

A cooling unit and double-circulation technology, applied in the field of cooling devices, can solve the problems of a large amount of sulfur-containing dust and water vapor, unsatisfactory cooling effect, and fast flue gas flow, so as to facilitate cooling and dust removal, solve the contradiction of cooling rate, and stop production short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

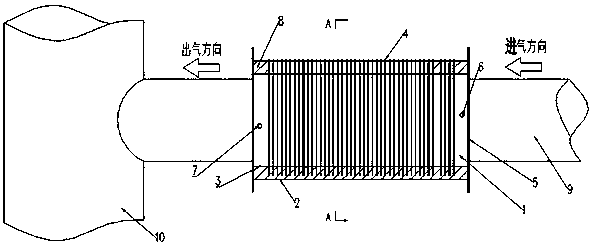

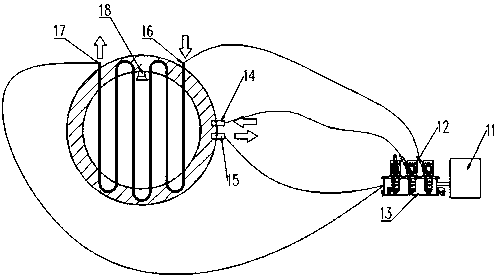

[0030] figure 1 It is a structural schematic diagram of a cooling unit connected and installed with the flue pipe 9 and the desulfurization device 10 in a preferred embodiment of the present invention. from figure 1 It can be seen that the cooling unit is a cylindrical double-shell structure, and the two ends are provided with the connection with the smoke pipe 9, and the mechanism 5 (flange). In addition to the connection mechanism 5, the body 1 of the cooling unit has an outer shell 2 and an inner tube 3 inside, and several groups of cooling tubes 4 are arranged radially along the inner tube 3. Each group of cooling pipes 4 is fixedly connected with the inner pipe 3 and the outer shell 2 . The cooling pipe 4 is provided with an inlet and an outlet for the cooling medium to enter and flow out. Adjacent cooling pipes 4 are arranged in a staggered manner by pressing seams to block the high-heat flue gas circulating in the inner pipe, so as to prolong the residence time of th...

specific Embodiment approach 2

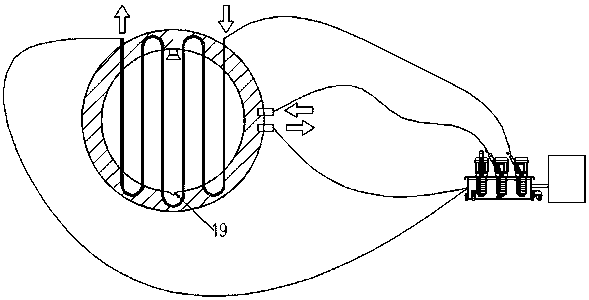

[0035] image 3 It is a structural schematic diagram of another preferred embodiment of the present invention. The difference between this embodiment and the first embodiment is that there is still a diversion groove 19 at the bottom of the inner pipe 3, so as to guide the condensed water vapor or the flushing spray liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com