Preparation method and application of transparent electrode of ultraviolet light-emitting diode

A technology of light-emitting diodes and transparent electrodes, applied in chemical instruments and methods, circuits, electrical components, etc., can solve the problems of low specific contact resistance of transparent conductive films, achieve low forward operating voltage, promote application, and high light extraction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

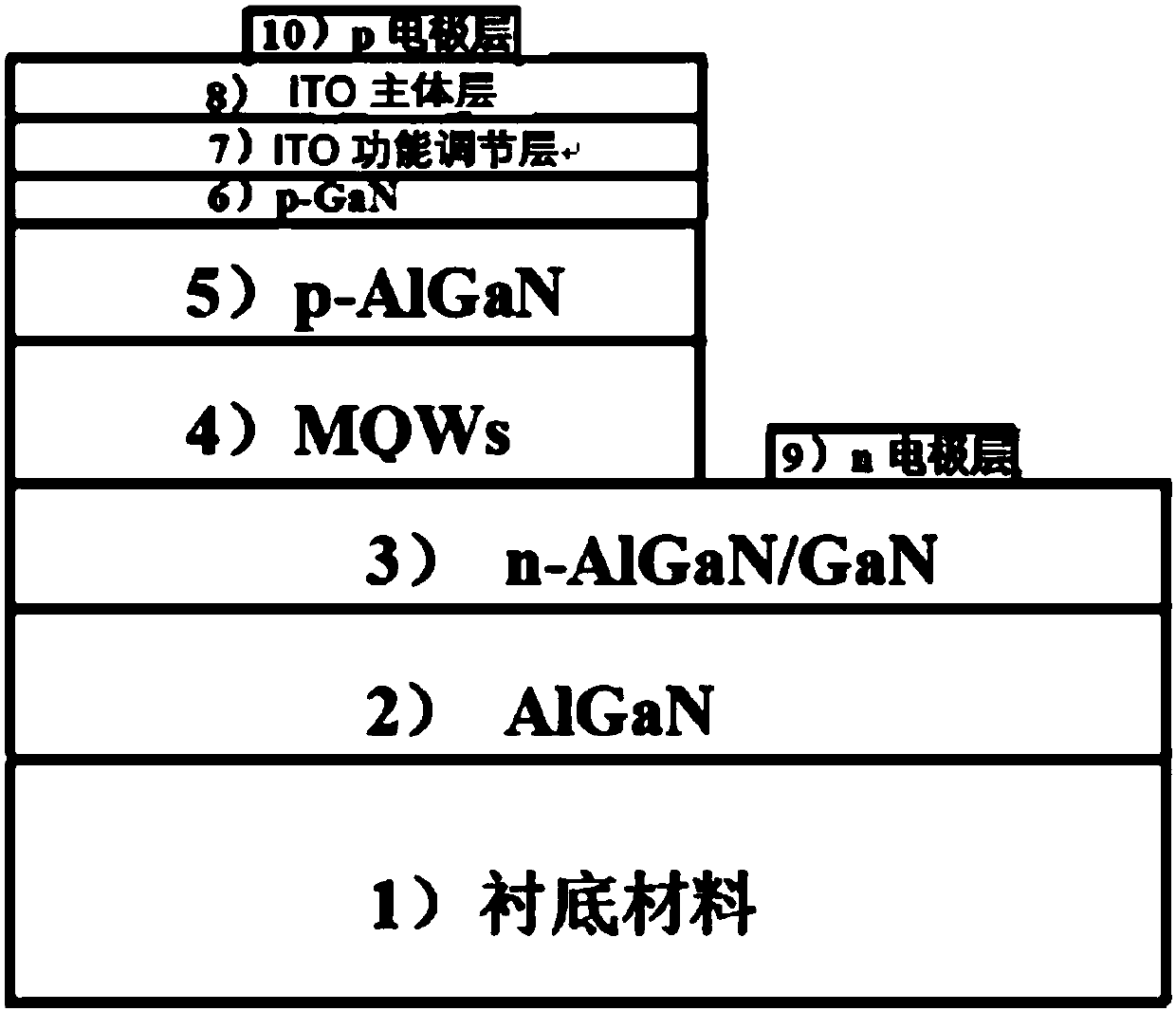

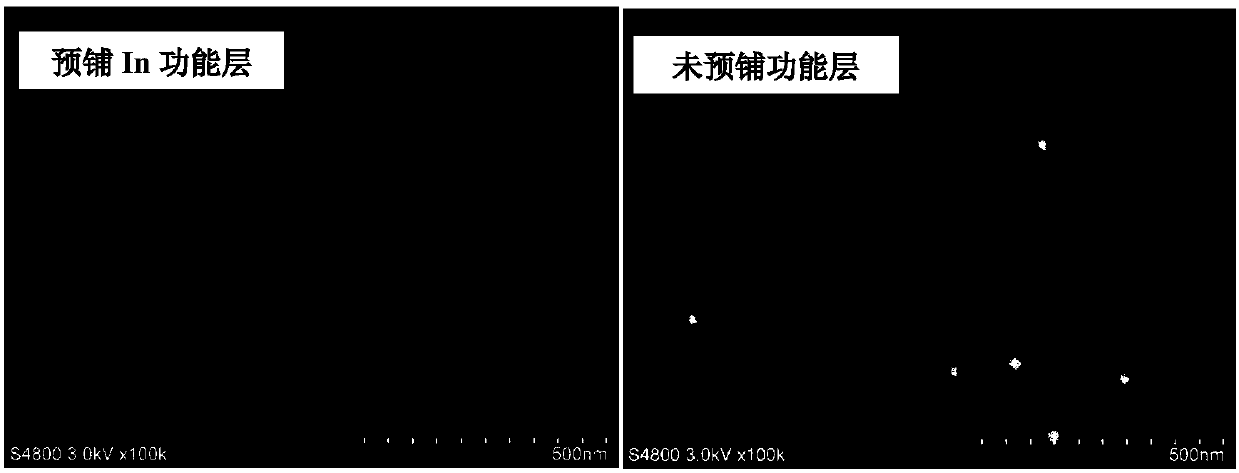

[0038] Using the existing MOCVD equipment, using organometallic trimethyl indium as the indium source, organometallic tetrakis (dimethylamino) tin source, oxygen with a purity of 99.9999% as the oxygen source, argon as the carrier gas and growth protective atmosphere, in the epitaxial wafer A functional adjustment layer of pre-applied organometallic In source is grown on the ultraviolet 365nm LED, and then a layer of ITO film is deposited as the main layer.

[0039] The preparation method of the function adjustment layer and the main body layer is as follows:

[0040] 1. Pretreatment before growing the substrate: Using 365nm UV LED epitaxial wafer as the substrate material, the surface of the substrate material is cleaned with organic and inorganic acid and alkali to prevent contact with air and put it into the MOCVD reaction chamber as soon as possible.

[0041] 2. Growth of the functional adjustment layer: the growth temperature is controlled at 530° C., the pressure in the ...

Embodiment 2

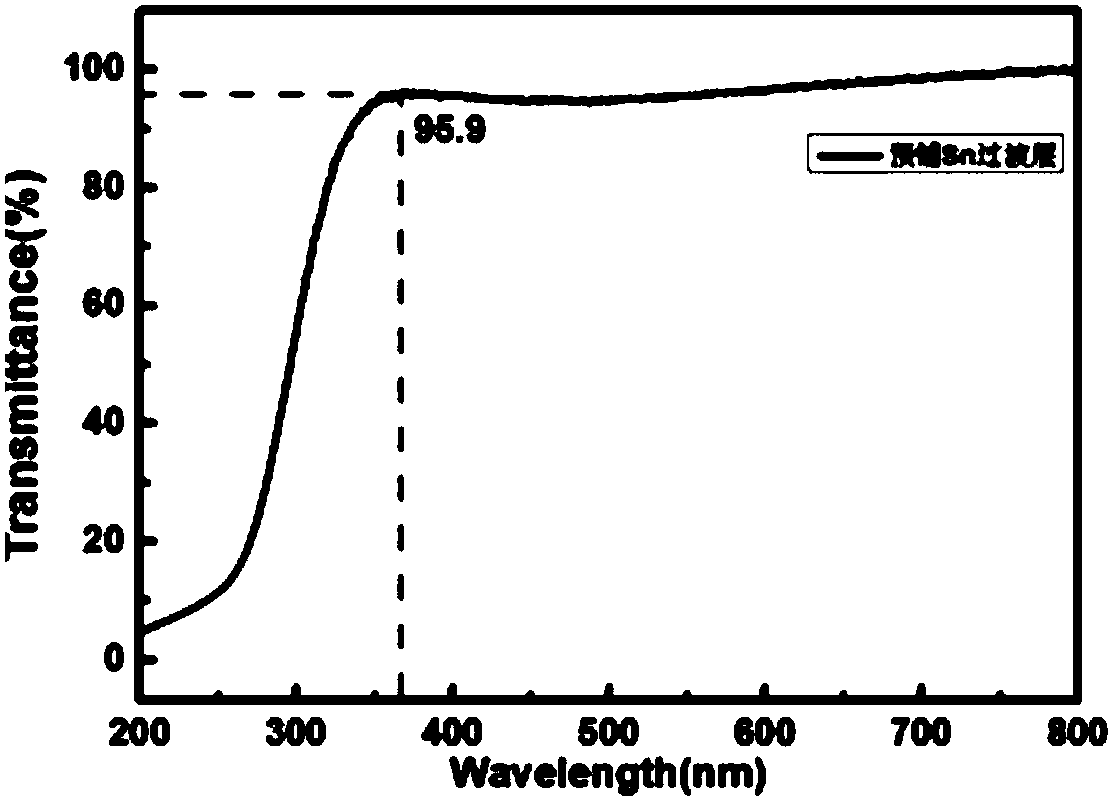

[0046] Using the existing MOCVD equipment, using organometallic trimethyl indium as the indium source, organometallic tetrakis (dimethylamino) tin source, oxygen with a purity of 99.9999% as the oxygen source, argon as the carrier gas and growth protective atmosphere, in the epitaxial wafer A layer of pre-spreading organometallic Sn function adjustment layer is grown on the ultraviolet 365nm LED, and then a layer of ITO film is deposited as the main layer.

[0047] The preparation method of the function adjustment and the main body layer is as follows:

[0048] 1. Pretreatment before growing the substrate: Using 365nm UV LED epitaxial wafer as the substrate material, the surface of the substrate material is cleaned with organic and inorganic acid and alkali to prevent contact with air and put it into the MOCVD reaction chamber as soon as possible.

[0049] 2. Growth of functional adjustment layer: the growth temperature is controlled at 530°C, the pressure of the reaction cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com