Deeply-hydrolyzed protein formula powder and technology making method

A technology of hydrolyzed protein and process method, applied in the field of deeply hydrolyzed protein formula powder and process manufacturing, can solve the problem of not avoiding lactose intake, and achieve the effects of preventing lactose intolerance, reducing the recurrence rate of eczema, and avoiding delayed treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

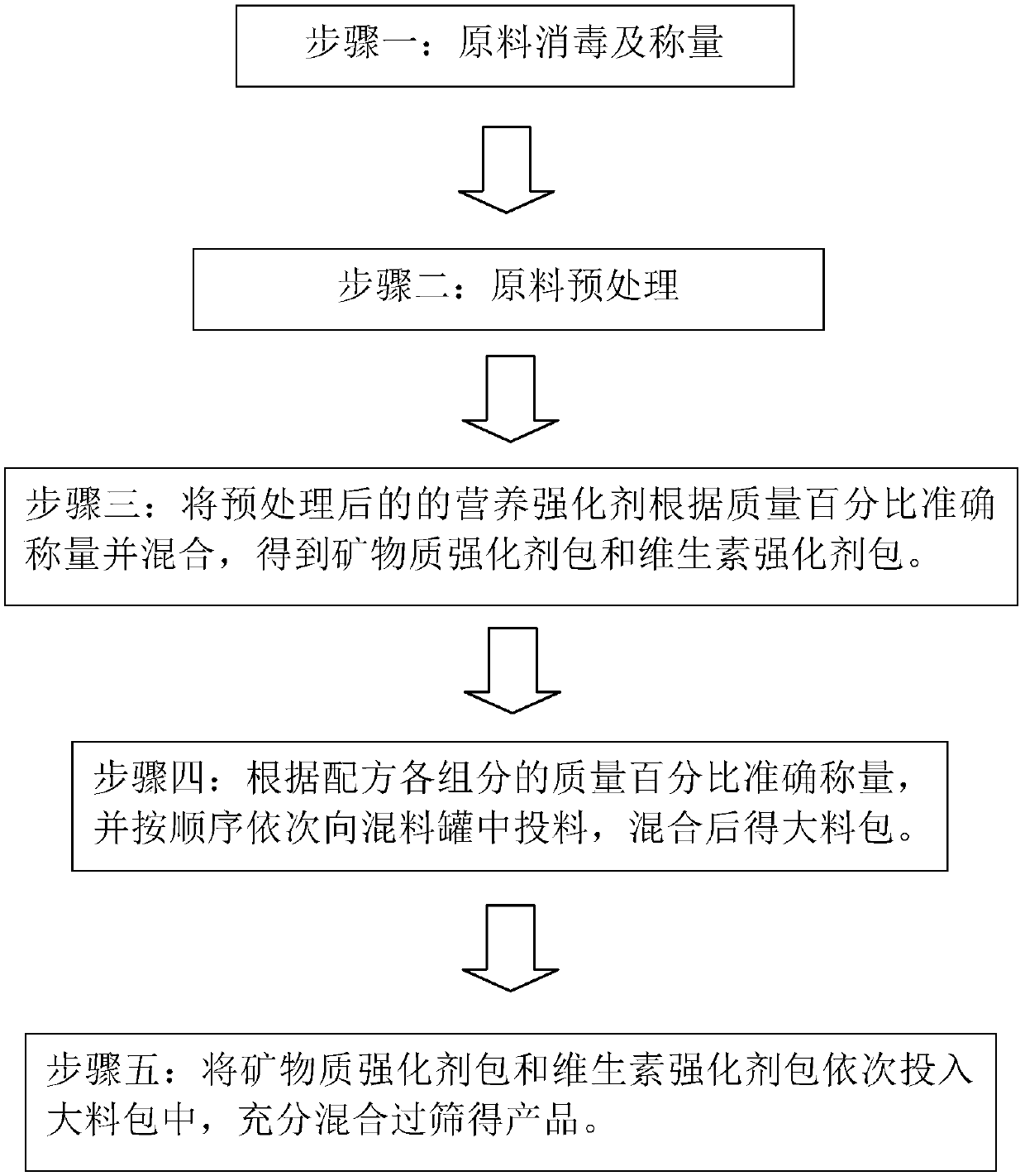

Method used

Image

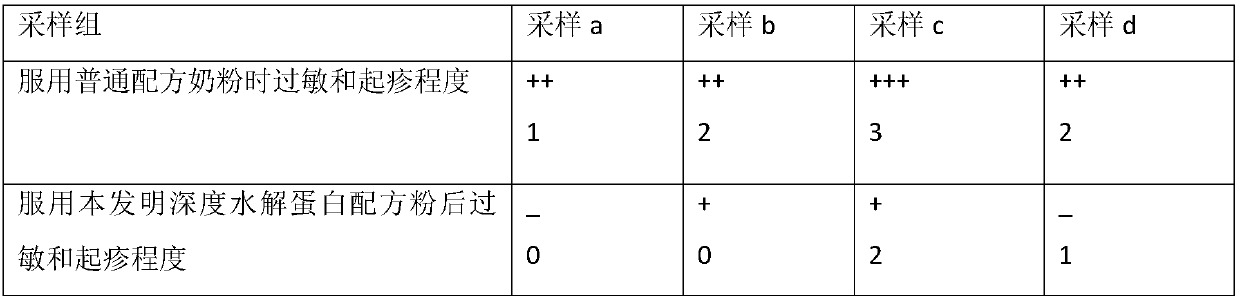

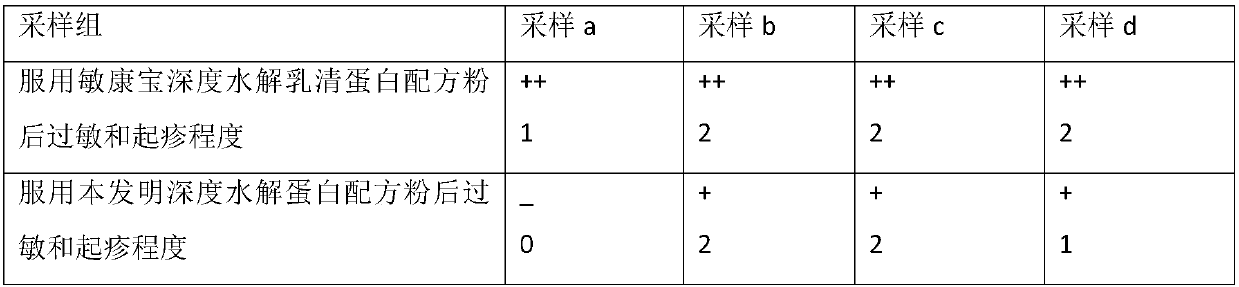

Examples

Embodiment 1

[0088] Deeply hydrolyzed protein formula powder, including oiled demineralized whey ingredient powder, solid corn syrup, deep hydrolyzed whey protein powder, galactooligosaccharide, nutrition enhancer, arachidonic acid powder, docosahexaenoic acid powder, lactose Enzyme, oligofructose, mass parts of each component: 64.5 parts of oiled desalted whey ingredient powder, 13.91 parts of solid corn syrup, 4 parts of deep hydrolyzed protein powder, 0.58 parts of galacto-oligosaccharides, 0.06 parts of oligofructose, nutrition fortification 0.93 parts of docosahexaenoic acid powder, 0.30 parts of arachidonic acid powder, 0.10 parts of lactase.

[0089] Among them, the degree of hydrolysis of deeply hydrolyzed whey protein powder is 25; including oligopeptides with a molecular weight of less than 1000, polypeptides with a molecular weight between 1000-5000, and polypeptides with a molecular weight greater than 5000. The mass of each component: oligopeptides with a molecular weight of less ...

Embodiment 2

[0122] Deeply hydrolyzed protein formula powder, including oiled demineralized whey ingredient powder, solid corn syrup, deep hydrolyzed whey protein powder, galactooligosaccharide, nutrition enhancer, arachidonic acid powder, docosahexaenoic acid powder, lactose Enzyme, oligofructose, mass parts of each component: 72.30 parts of oiled desalted whey ingredient powder, 14.30 parts of solid corn syrup, 9.04 parts of deep hydrolyzed protein powder, 1.98 parts of galacto-oligosaccharide, 0.22 parts of oligofructose, nutrition fortification 1.11 parts, docosahexaenoic acid powder 0.3 parts, arachidonic acid powder 0.6 parts, lactase 0.15 parts.

[0123] Among them, the degree of hydrolysis of deeply hydrolyzed whey protein powder is 25; including oligopeptides with a molecular weight of less than 1,000, polypeptides with a molecular weight between 1,000 and 5,000, polypeptides with a molecular weight of 5,000 to 20,000, and polypeptides with a molecular weight of more than 20,000. Num...

Embodiment 3

[0152] Deeply hydrolyzed protein formula powder, including oiled demineralized whey ingredient powder, solid corn syrup, deep hydrolyzed whey protein powder, galactooligosaccharide, nutrition enhancer, arachidonic acid powder, docosahexaenoic acid powder, lactose Enzyme, oligofructose, mass parts of each component: 75.8 parts of oiled desalted whey ingredient powder, 22.99 parts of solid corn syrup, 10.38 parts of deep hydrolyzed protein powder, 4.50 parts of galacto-oligosaccharides, 4.22 parts of fructooligosaccharides, nutrition fortification 1.50 parts of docosahexaenoic acid powder, 0.46 parts of arachidonic acid powder, 0.69 parts of arachidonic acid powder, and 0.25 parts of lactase.

[0153] Among them, the degree of hydrolysis of deeply hydrolyzed whey protein powder is 25; including oligopeptides with a molecular weight of less than 1,000, polypeptides with a molecular weight of between 1,000 and 5,000, and polypeptides with a molecular weight of more than 20,000. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com