Anti-corrosion pot and preparation method thereof

A technology for cookware and anti-corrosion layer, which is applied to the field of anti-corrosion cookware and its preparation, can solve the problem that the wear resistance and corrosion resistance of rust-proof iron cookware are difficult to balance, and achieve strong wear resistance, good corrosion resistance and hardness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

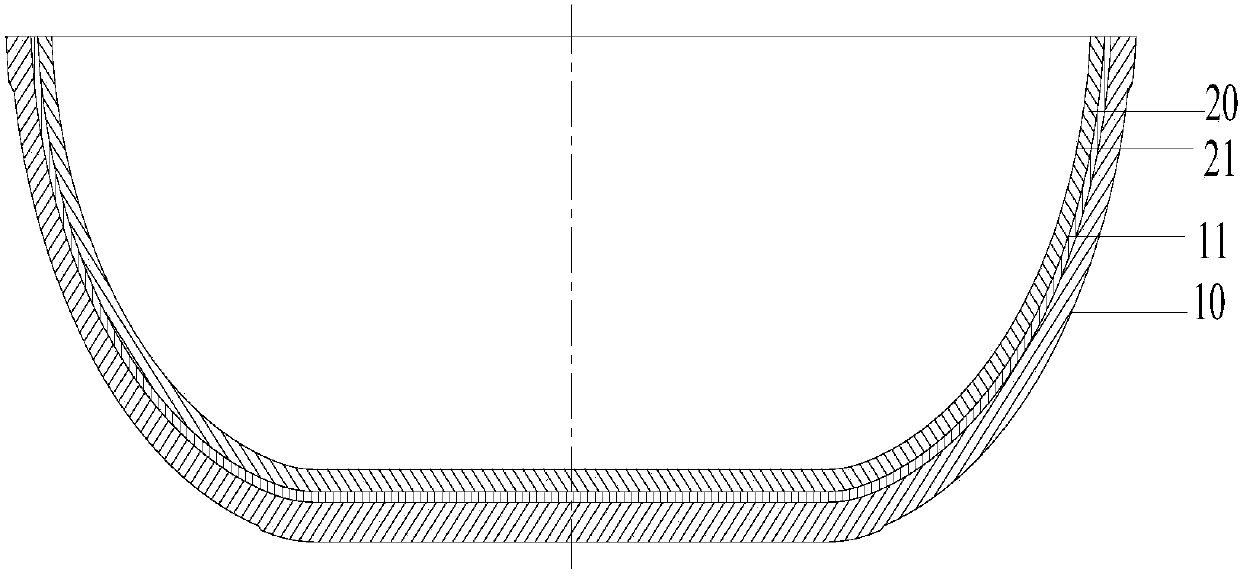

[0036] In another typical embodiment of the present application, a method for preparing an anti-corrosion cooker is also provided, the preparation method comprising: forming an anti-corrosion layer 20 on the first surface of the base layer 10 of the cooker by a solid-phase reaction method, Thereby the antiseptic pot is obtained.

[0037] The above preparation method forms the anticorrosion layer 20 by using the solid phase reaction method, which not only improves the preparation efficiency of the anticorrosion layer 20, but also due to the particle rearrangement, material transfer, gas filling and crystallization between the constituent elements of the anticorrosion layer 20 during the solid phase reaction process grain growth, the formed anti-corrosion layer 20 is uniform in composition, and there is no potential difference. Not only will there be no pitting and perforation phenomenon that occurs in the anti-rust iron pan with nitriding and oxidation treatment, but also it has...

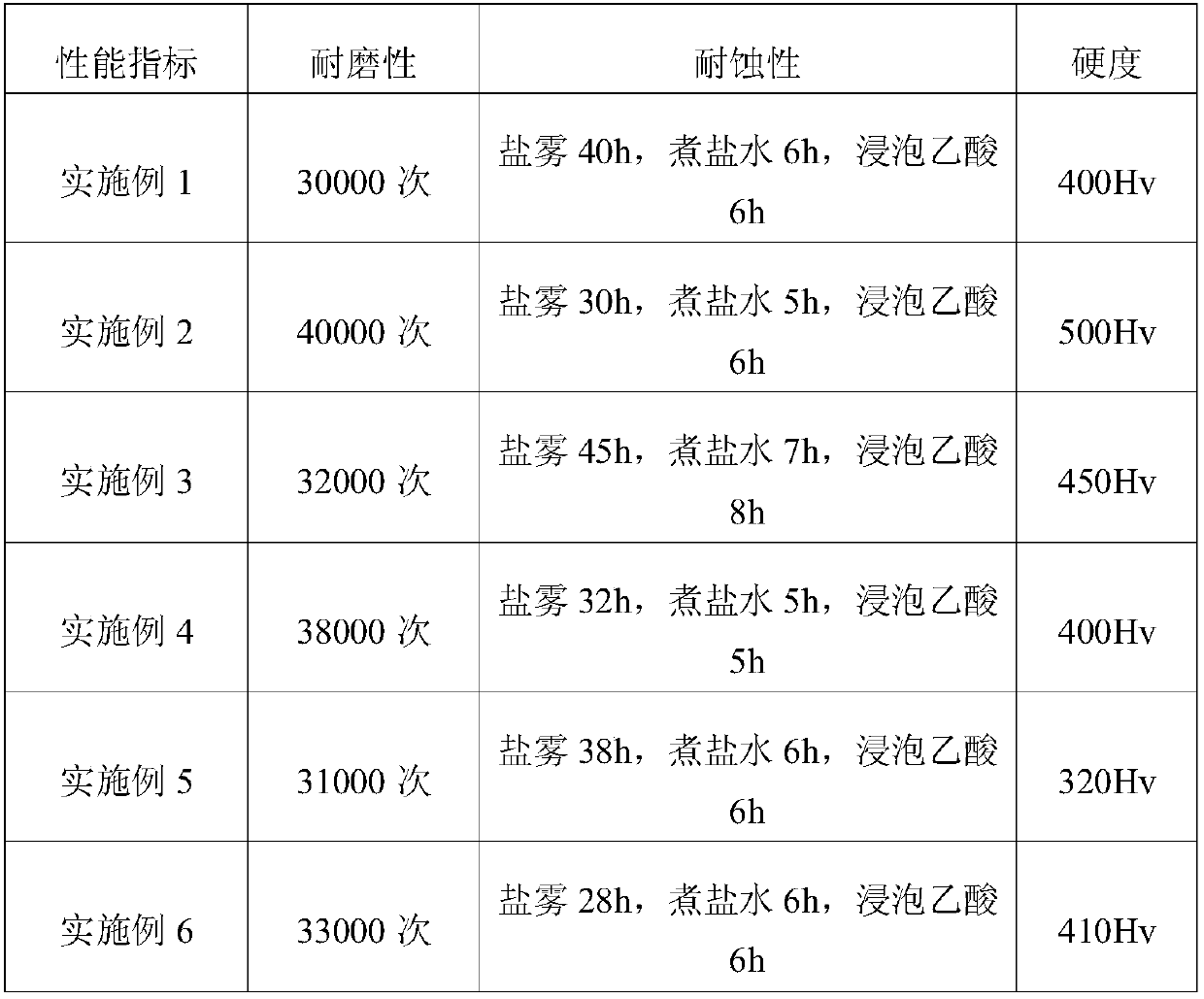

Embodiment 1

[0044] Fe and TiO 2 Powders with a particle size of 5 μm were prepared by electrolysis, respectively, and the above two powders were mixed according to a mass ratio of 7:3 to obtain 70 g of mixed powders.

[0045] Add 0.03g sintering aid HBO to the mixed powder 3 And 29.97g organic solvent polyethylene glycol is mixed further, obtains slurry;

[0046] The slurry is coated on the first surface of the iron pan base layer 10 to form the iron pan body;

[0047] Put the iron pan green body at 400° C. for sintering, and sinter at this temperature for 60 minutes to obtain an anti-corrosion pan, wherein the anti-corrosion layer 20 has a thickness of 5 μm.

Embodiment 2

[0049] Fe and Al 2 o 3 The powders with a particle size of 15 μm were respectively prepared by electrolysis, and the above-mentioned various powders were mixed according to a mass ratio of 6:4 to obtain 98 g of mixed powders.

[0050] Add 2g of organic solvent sodium carboxymethyl cellulose to the mixed powder for further mixing to obtain a slurry;

[0051] The slurry is coated on the first surface of the low-carbon steel pot base layer 10 to form a pot body; wherein, the first surface is a sandblasting surface formed by sandblasting, wherein the roughness of the sandblasting surface is 1.2 μm;

[0052] The pot body was sintered at 900° C. for 5 minutes at this temperature to obtain an anti-corrosion pot, wherein the anti-corrosion layer 20 had a thickness of 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com