Porous carbon material for treating organic dye and fluoride-containing waste water, and preparation method thereof

A porous carbon material, wastewater treatment technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

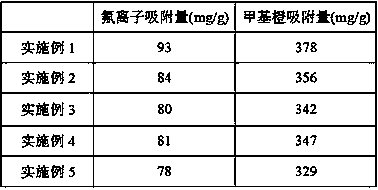

Embodiment 1

[0021] Take 1 g of polyvinyl alcohol and dissolve it in 10 g of deionized water, heat and stir to dissolve to obtain an aqueous solution of polyvinyl alcohol; take 1 g of chitosan and 3 g of aluminum chloride, add them to 96 g of deionized water, heat and stir to dissolve, and obtain Chitosan aqueous solution; Stir and mix the obtained chitosan aqueous solution and polyvinyl alcohol aqueous solution, and then add 20 mL, 10 wt% glutaraldehyde aqueous solution to cross-link to obtain polyvinyl alcohol / chitosan hydrogel; polyvinyl alcohol / Chitosan hydrogel is freeze-dried, then sent to a tube furnace, and carbonized at 700°C under a nitrogen atmosphere for 2 hours to obtain carbon aerogels, which are added to 1 M dilute hydrochloric acid solution for soaking After 2 hours, rinse repeatedly with absolute ethanol, and dry to constant weight to obtain a porous carbon material.

[0022] The surface morphology of the prepared porous carbon material is shown in figure 1 shown.

Embodiment 2

[0024] Take 1 g of polyvinyl alcohol and dissolve it in 10 g of deionized water, heat and stir to dissolve to obtain an aqueous solution of polyvinyl alcohol; take 1 g of chitosan and 3 g of aluminum chloride, add them to 96 g of deionized water, heat and stir to dissolve, and obtain Chitosan aqueous solution; Stir and mix the obtained chitosan aqueous solution and polyvinyl alcohol aqueous solution, and then add 20 mL, 10 wt% glutaraldehyde aqueous solution to cross-link to obtain polyvinyl alcohol / chitosan hydrogel; polyvinyl alcohol / Chitosan hydrogel is freeze-dried, then sent to a tube furnace, and carbonized at 600 ° C for 2 hours under a nitrogen atmosphere to obtain carbon aerogels, which are added to 1 M dilute hydrochloric acid solution for soaking After 2 hours, rinse repeatedly with absolute ethanol, and dry to constant weight to obtain a porous carbon material.

Embodiment 3

[0026] Take 1 g of polyvinyl alcohol and dissolve it in 10 g of deionized water, heat and stir to dissolve to obtain an aqueous solution of polyvinyl alcohol; take 2 g of chitosan and 3 g of aluminum chloride, add them to 95 g of deionized water, heat and stir to dissolve, and obtain chitosan aqueous solution; the obtained chitosan aqueous solution and polyvinyl alcohol aqueous solution were stirred and mixed, and then 30 mL, 10 wt% glutaraldehyde aqueous solution was added for cross-linking to obtain polyvinyl alcohol / chitosan hydrogel; polyvinyl alcohol / Chitosan hydrogel is freeze-dried, then sent to a tube furnace, and carbonized at 600 ° C for 2 hours under a nitrogen atmosphere to obtain carbon aerogels, which are added to 1 M dilute hydrochloric acid solution for soaking After 2 hours, rinse repeatedly with absolute ethanol, and dry to constant weight to obtain a porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com