Seven-axis five-linkage wood plug CNC machining center and method

A processing center and five-linkage technology, which is applied in tenon and groove processing, and in the field of tenon and tenon of various woods, can solve the problems of high labor intensity, inability to process long wood, and low production efficiency, so as to improve work flexibility and broaden processing range, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

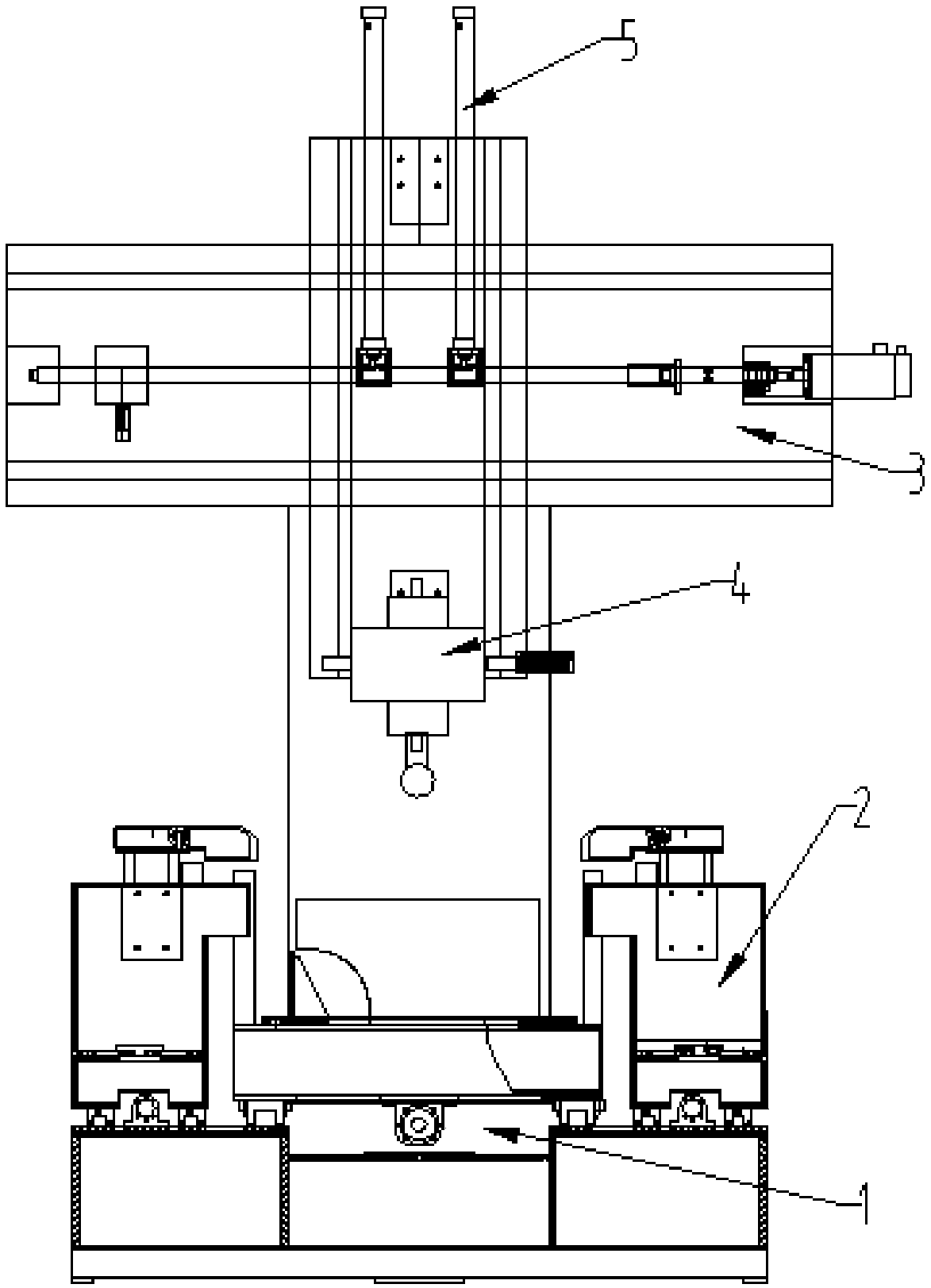

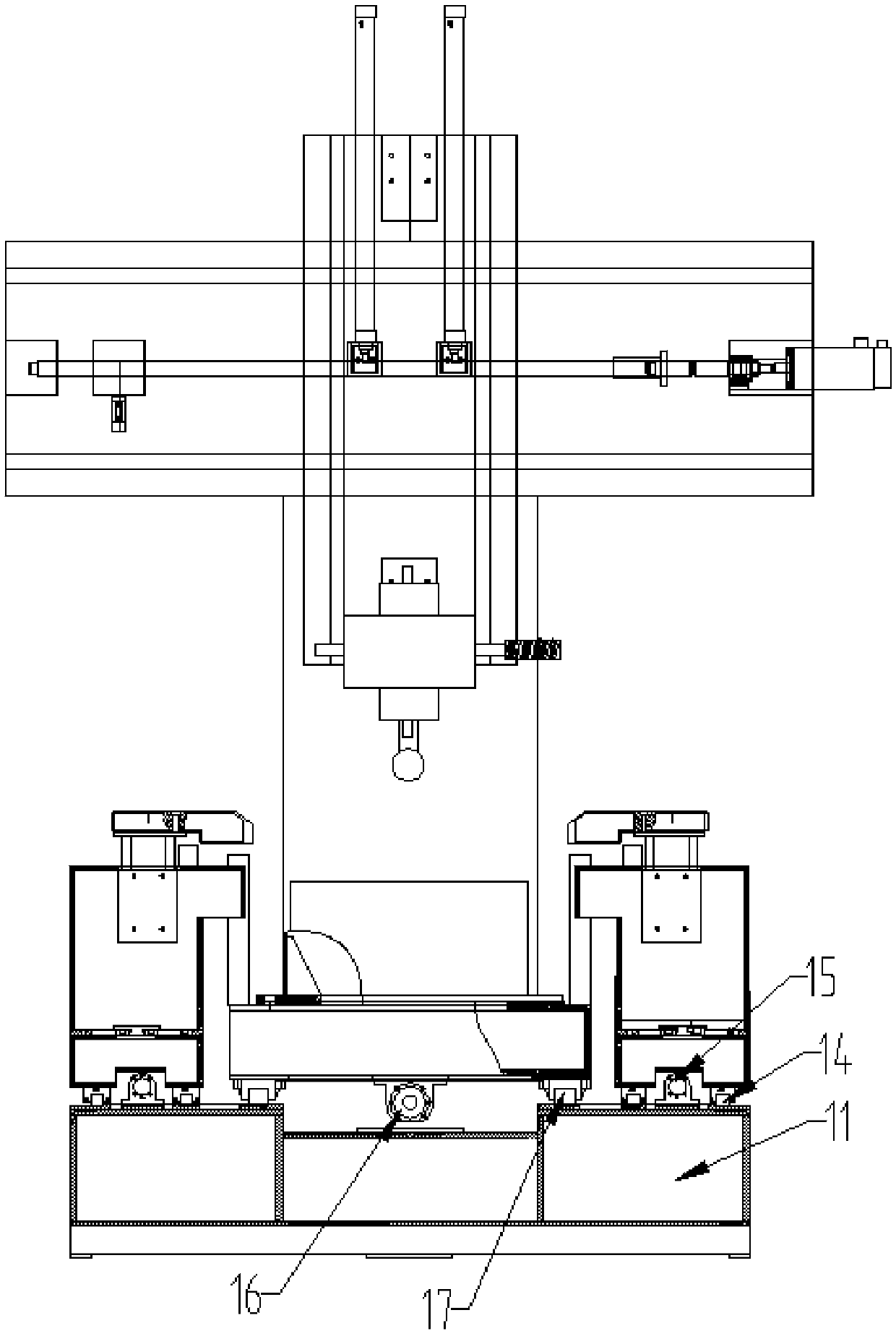

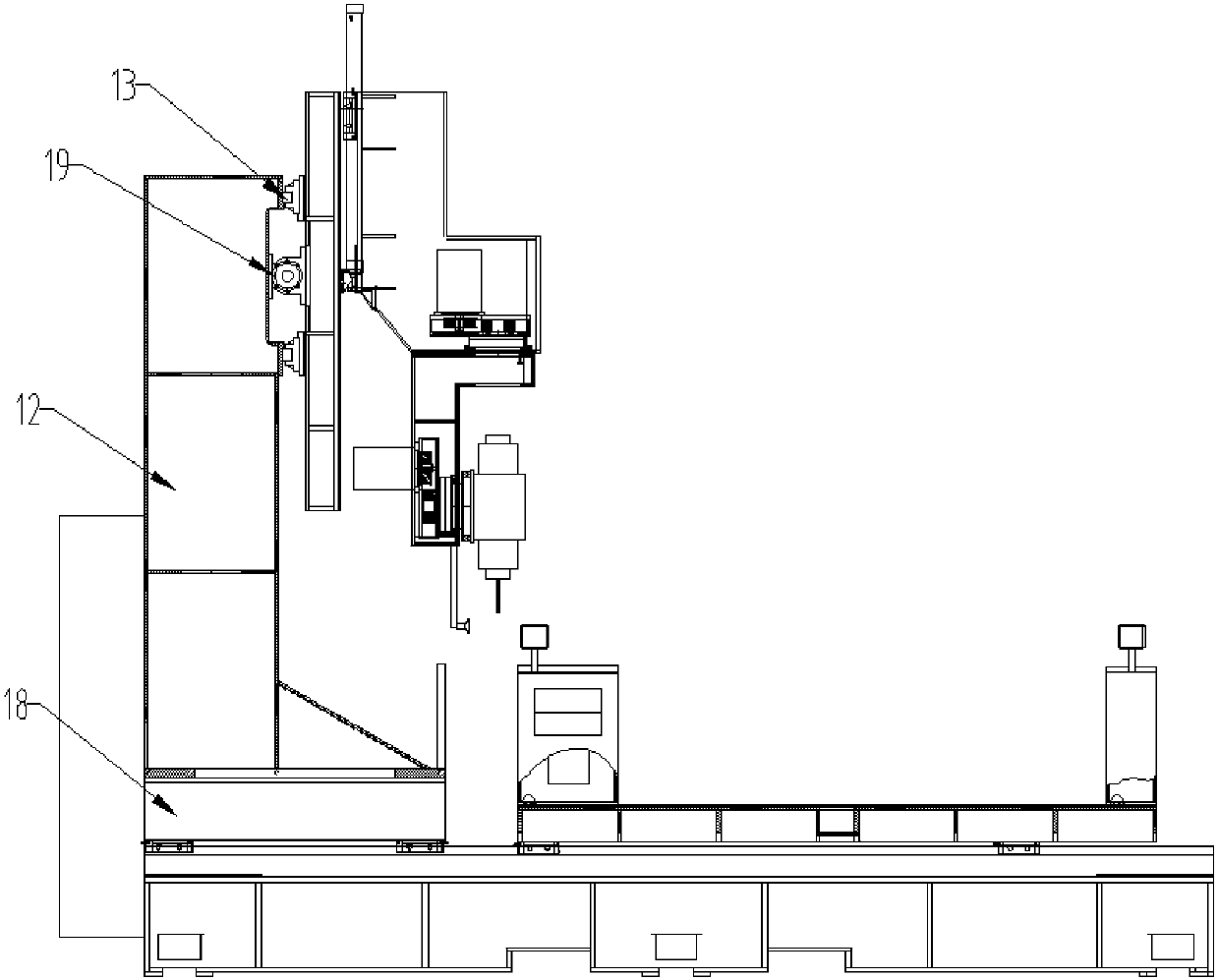

[0034] Such as figure 1 As shown, the wooden tenon CNC machining center includes a body assembly 1, a worktable assembly 2, a tool seat moving assembly 3, a tool seat assembly 4, and a pneumatic and chip removal assembly 5.

[0035] The workbench assembly 2, the tool seat moving assembly 3 are movably connected to the fuselage assembly 1, the pneumatic and chip removal assembly 5 is fixedly connected to the machine body assembly 1, the tool seat assembly 4 and the tool seat moving assembly 3 rotatable connections.

[0036] The fuselage assembly 1 provides fixed support for each assembly, the workbench assembly 2 clamps and positions the tool setting points for wooden workpieces of various lengths and shapes, and the tool holder moving assembly 3 realizes the two-plane movement of the tool holder degrees of freedom and two rotational degrees of freedom, the tool holder assembly 4 realizes the positioning and clamping of four tools and provides cutting rotation power, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com