Method for recovering elemental sulfur through photoinduced catalytic disproportionation through sulfur dioxide absorption liquid

A technology of sulfur dioxide and absorption liquid, which is applied in the direction of sulfur preparation/purification, etc., can solve the problems of difficult separation of catalyst and sulfur colloid, secondary pollution, etc., and achieve the effect of being conducive to industrial application, short process, and solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Analytical pure H 2 SO 3 , to analyze pure KI.

[0020] Add 50mLH to the photochemical reactor with cooling water jacket, inert gas protection and magnetic stirring 2 SO 3 and 9.96g KI, 0.2L / min N 2 Continue for 30 minutes to remove the air, place the fully wrapped and sealed reactor with tin foil under a xenon lamp light source for vertical irradiation, adjust the current to 20A, and circulate and cool with normal temperature water, stop the irradiation after 9 hours, and no elemental sulfur is formed.

Embodiment 2

[0022] Analytical pure H 2 SO 3 , to analyze pure KI.

[0023] Add 50mLH to a photochemical reactor with cooling water jacket, inert gas protection and magnetic stirring 2 SO 3 , 0.2L / minN 2 Continue for 30 minutes to remove the air. After sealing, place the reactor under a xenon lamp light source to irradiate vertically, adjust the current to 20A, and cool it with normal temperature water circulation. After 9 hours, stop the irradiation, and no elemental sulfur is formed.

Embodiment 3

[0025] Analytical pure NaOH, analytical pure KI.

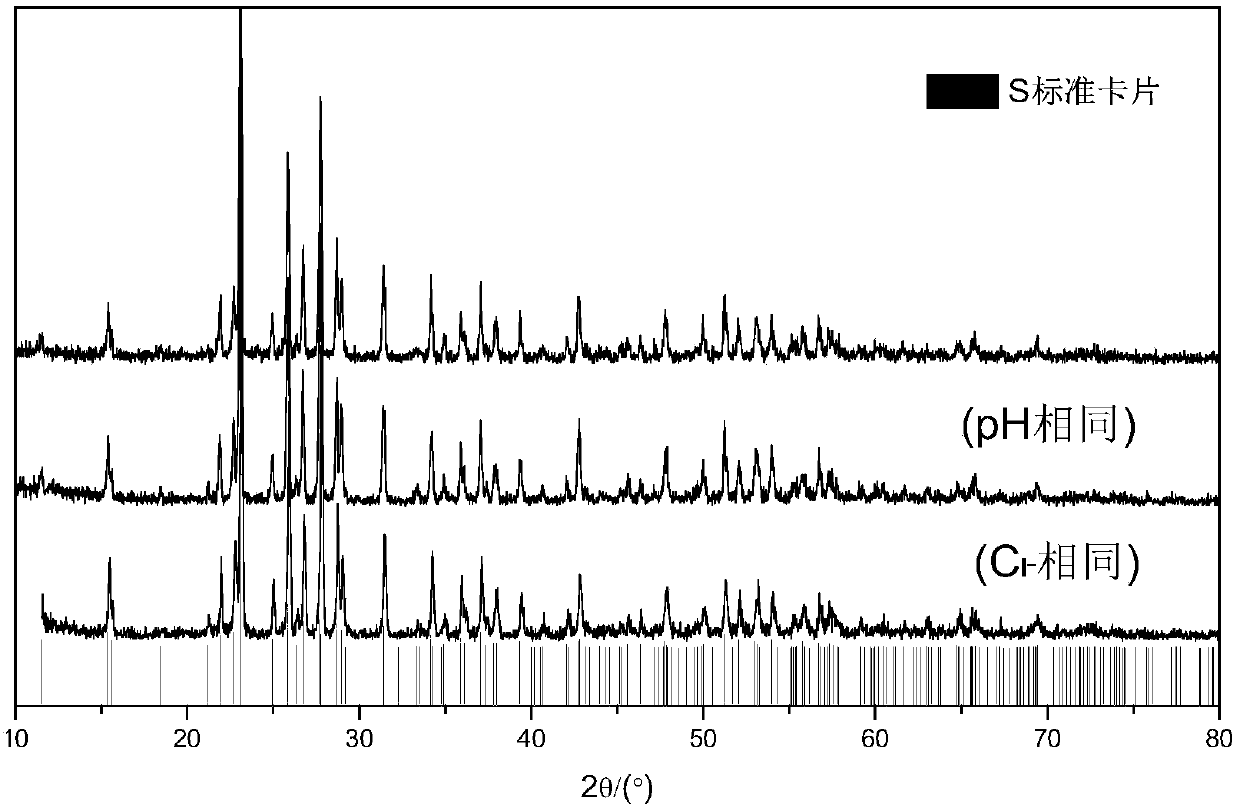

[0026] Add 50mL of 1mol / L NaOH and 11.62g of KI in a photochemical reactor containing a cooling water jacket, inert gas protection and magnetic stirring, and continuously feed pure SO 2 Gas (0.2L / min) to pH<2, the solution is yellow at this time, after sealing, put the reactor under the xenon lamp light source to irradiate vertically, adjust the current to 20A, cool with normal temperature water circulation, stop the irradiation after 9h, there are more As a yellow solid substance, filter and dry the substance at 60°C to constant weight, and XRD detection proves that the solid product is elemental S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com