Method for removing algae through strengthening coagulation by using peroxy carbonate

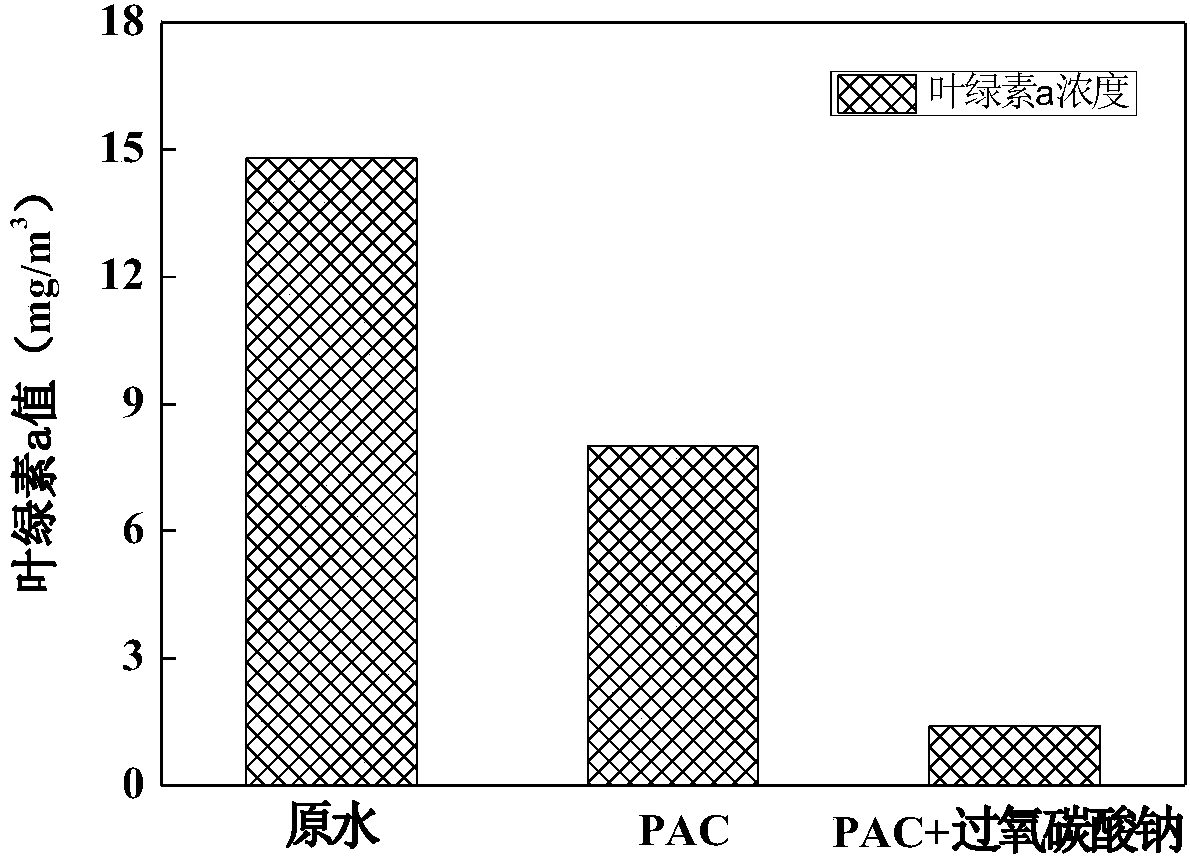

A peroxycarbonate and carbonate technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve problems such as low algae removal efficiency, poor precipitation effect, and secondary pollution. , to achieve the effect of enhancing coagulation effect, avoiding secondary pollution and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Mix sodium percarbonate and polyaluminum chloride (PAC) according to the ratio of volume to mass ratio of 1:9 to form a mixed agent;

[0041] 2) Add the mixed agent in step 1) into the algae-containing water body, and the concentration of the mixed agent added in the algae-containing water body is respectively: PAC45mg / L, sodium percarbonate 5mg / L;

[0042] 3) After the addition is completed, stir the water body at a rapid speed of 100r / min, a medium speed of 80r / min, and a slow speed of 30r / min, and then settle for 30 minutes to complete the algae removal process.

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is: described peroxycarbonate is potassium peroxycarbonate; Described coagulant is the mixture of ferrous sulfate, potassium aluminum sulfate, the mixture of potassium peroxycarbonate and coagulant The volume-to-mass ratio is 1:1; the speeds of the fast, medium and slow stirring are: 80r / min, 60r / min, and 30r / min respectively; the settling time is 35min; The total concentration in water is 40mg / L.

Embodiment 3

[0046] The difference between embodiment 3 and embodiment 1 is: described peroxycarbonate is sodium percarbonate; Described coagulant is the mixture of sodium aluminate and iron sulfate, the volume of sodium percarbonate and coagulant The mass ratio is 1:5; the speeds of the fast, medium and slow stirring are: 200r / min, 150r / min, 50r / min respectively; the static settling time is 40min; The total concentration is 250mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com