Preparation method and application of high-loading-capacity transition metal monatomic carbon-based catalyst

A technology based on carbon-based catalysts and transition metals, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of high cost and complicated process, and achieve the effect of strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

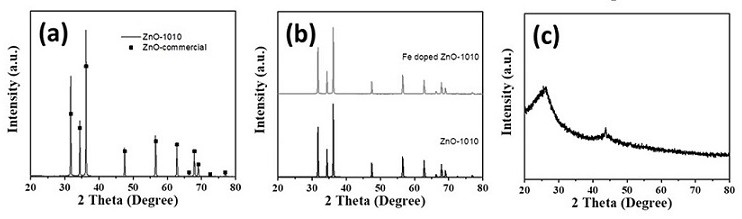

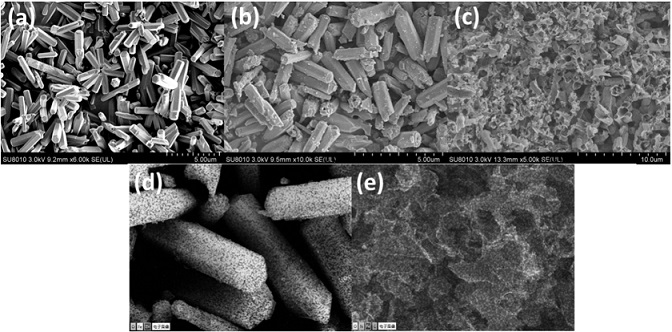

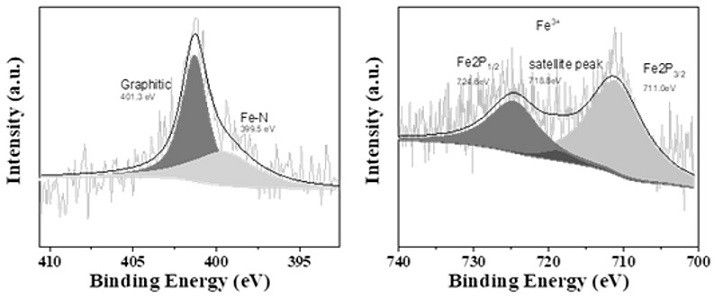

[0047] 1. Preparation of carbon-based catalyst supported by iron single atom: on the basis of synthesizing zinc oxide exposed to a special crystal plane (non-polar plane (1010)) supported by single atom iron, and 2-methylimidazole in an argon atmosphere In the high-temperature reaction in a tube furnace, the final catalyst is obtained in one step. Specifically:

[0048] (1) Weigh 0.407 g of iron-loaded zinc oxide and 0.977 g of 2-methylimidazole, and place them in a corundum boat with a cover of 2 cm*2 cm*10 cm, wherein the iron-loaded zinc oxide is placed in the middle of the corundum boat , corresponding to the downwind direction of the carrier gas; 2-methylimidazole is placed on the head of the corundum boat, corresponding to the upwind direction of the carrier gas.

[0049] (2) Put the corundum boat into the middle of a 4 cm*3mm*60cm quartz tube, then place the quartz tube in the tube furnace quartz tube, and place corundum plugs at both ends so that the corundum boat cor...

Embodiment 2

[0065] 1. Preparation of cobalt single-atom-supported carbon-based catalysts: On the basis of synthesizing single-atom cobalt-supported non-polar surface-exposed zinc oxide, and 2-methylimidazole in argon atmosphere in a tube furnace at high temperature reaction, the final catalyst is obtained in one step. Specifically:

[0066] (1) Weigh 0.407 g of cobalt-loaded zinc oxide and 0.977 g of 2-methylimidazole, and place them in a corundum boat with a cover of 2 cm*2 cm*10 cm, wherein the cobalt-loaded zinc oxide is placed in the middle of the corundum boat , corresponding to the downwind direction of the carrier gas; 2-methylimidazole is placed on the head of the corundum boat, corresponding to the upwind direction of the carrier gas.

[0067] (2) Put the corundum boat into the middle of a 4 cm*3mm*60cm quartz tube, then place the quartz tube in the tube furnace quartz tube, and place corundum plugs at both ends so that the corundum boat corresponds to the thermocouple position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com