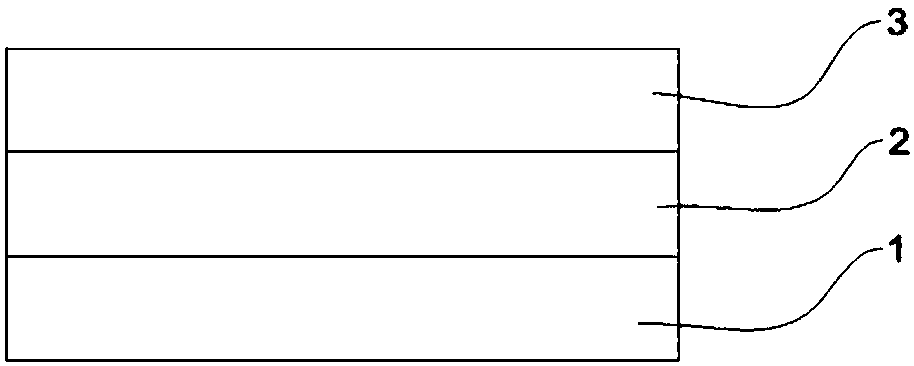

Anti-efflorescence facing mortar composite layer

A technology of facing mortar and composite layer, applied in the field of wall insulation materials, can solve the problems of insufficient strength and loss of ordinary cement support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

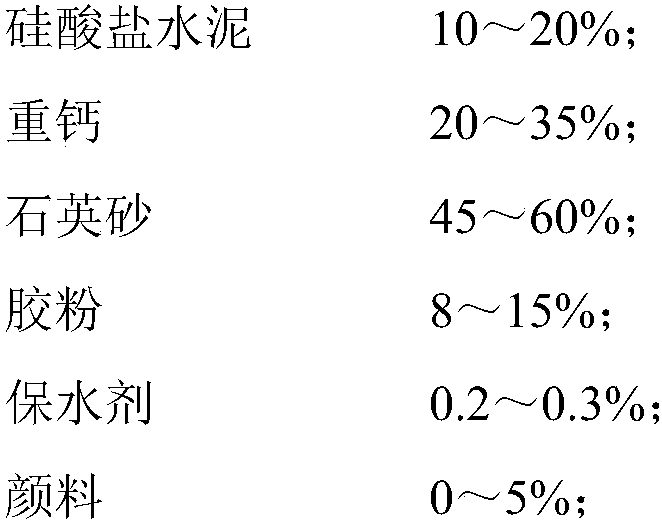

[0041] Table 1: This embodiment provides the formula table of the first layer of facing mortar:

[0042]

[0043]

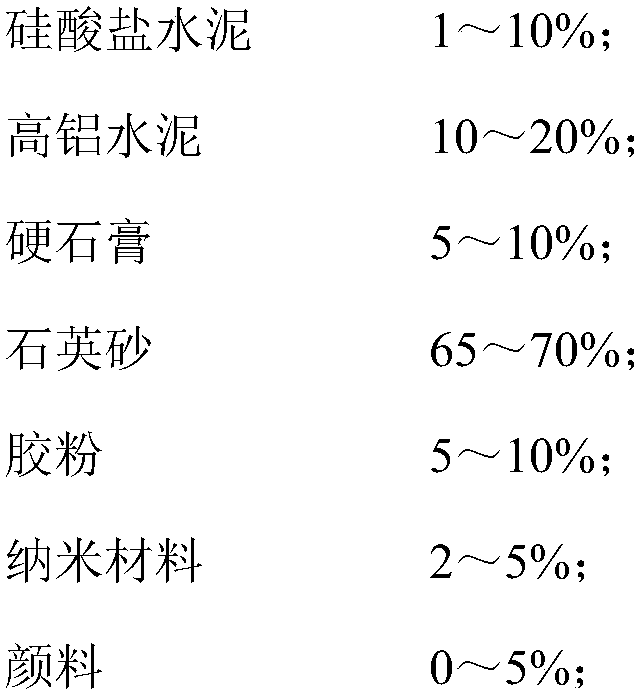

[0044] Table 2: This embodiment provides the formula table of the second layer of facing mortar

[0045]

[0046] Table 3: The present embodiment provides the formula table of the third hydrophobic layer

[0047]

[0048] According to the anti-panthenic alkali finishing mortar composite layer manufactured according to the above formula, the manufacturing steps are as follows:

[0049] 1) Add 20 parts of water into the container, and then pour 100 parts of raw materials in Table 1 into the water;

[0050] 2) Stir fully with an electric mixer to form a lump-free, uniform paste;

[0051] 3) Wait for the mortar to stand for 2-3 minutes and then stir for 1-2 minutes to obtain the first layer of facing mortar;

[0052] 4) Brush the first layer of finishing mortar on the wall with a brush;

[0053] 5) Add 20 parts of water into the container, and pour 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com