Method for preparing ethylidene norbornene by isomerization of vinyl norbornene

A technology of vinyl norbornene and ethylidene norbornene, which is applied in the field of isomerization of vinyl norbornene to prepare ethylidene norbornene, which can solve the problems of harsh preparation and storage conditions, large reaction temperature rise, and difficulty in control, etc. problems, achieve excellent catalytic performance, fast reaction rate, and easy control of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

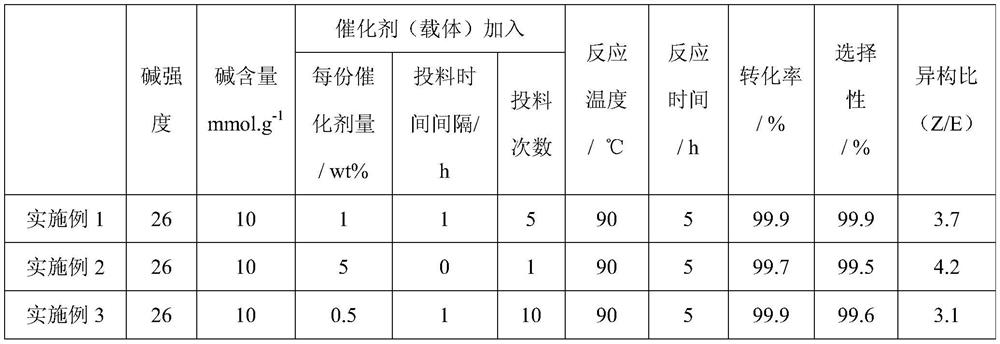

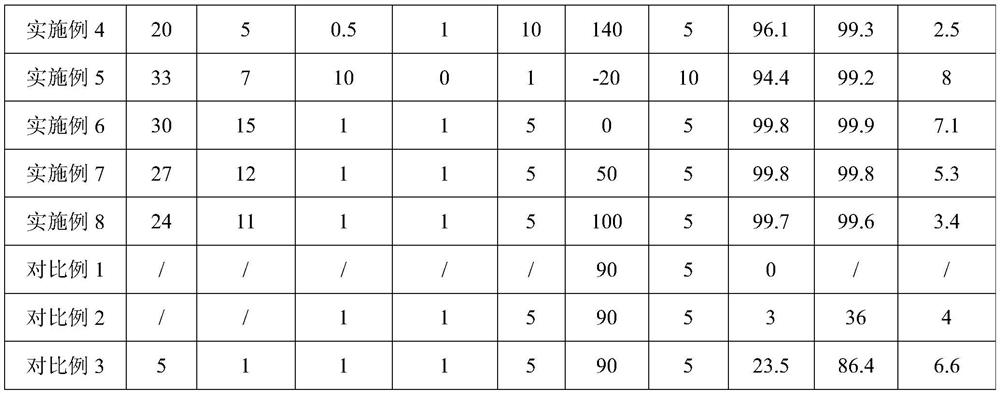

[0033] Embodiment 1. A method for preparing ethylidene norbornene by isomerizing vinyl norbornene:

[0034] 20g of AACH was calcined in an inert gas atmosphere at a temperature of 500°C for 4 hours to obtain a carrier. Weigh 5.18g (0.235mol) Na and 1.8g (0.045mol) NaOH, make a mixture, put them into a stirring tank and stir together, adjust the temperature to 500°C, react for 1h, and cool to obtain solid base catalyst A. After testing, its alkali strength is 26, and its alkali content is 10mmol.g -1 .

[0035] Take 100mL (84.1g) VNB and put it into the reactor, 2 (until the air in the reactor is completely replaced by N 2 ), heated to a constant temperature of 90°C. Weigh 5 parts of 1wt% (0.841g) catalyst A, totaling 5wt% (4.205g), add 1wt% catalyst at the beginning of the reaction, then add 1wt% catalyst every 1h. Sampling at intervals, analyzed by gas chromatography, calculating the conversion rate of the reaction, the isomerization ratio of the product, VNB is basicall...

Embodiment 2

[0036] Embodiment 2, a method for preparing ethylidene norbornene by isomerization of vinyl norbornene:

[0037] The catalyst was prepared as described in Example 1.

[0038] Take 100mL (84.1g) VNB and put it into the reactor, 2, heated to a constant temperature of 90°C. Weigh 1 part of 5wt% (4.205g) catalyst A and add it to the reaction kettle at one time. Sampling at intervals, analyzed by gas chromatography, calculating the conversion rate of the reaction, the isomerization ratio of the product, VNB is basically converted into ENB during 5h, the reaction conversion rate is 99.7%, the selectivity is 99.5%, and the isomerization ratio Z / E is 4.2. After filtering, the filtrate is the product - ethylidene norbornene (ENB), with a purity of 98.7%.

Embodiment 3

[0039] Embodiment 3, a method for preparing ethylidene norbornene by isomerization of vinyl norbornene:

[0040] The catalyst was prepared as described in Example 1.

[0041] Take 100mL (84.1g) VNB and put it into the reactor, 2 , heated to a constant temperature of 90°C. Weigh 10 parts of 0.5wt% (0.4205g) catalyst A, totaling 5wt% (4.205g), and add 0.5wt% catalyst every 1h. Sampling at intervals, using gas chromatographic analysis to calculate the conversion rate of the reaction, the isomerization ratio of the product, VNB is basically converted into ENB in the time of 10h, the reaction conversion rate is 99.9%, the selectivity is 99.6%, the isomerization ratio Z / E is 3.1. After filtration, the filtrate is the product - ethylidene norbornene (ENB), with a purity of 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com