System and method for separating alpha-pinene and beta-pinene in turpentine

A separation system and turpentine technology, which are applied in separation methods, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve the problems of high production cost, reduced rectification purity, and large production energy consumption, and achieve continuous production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

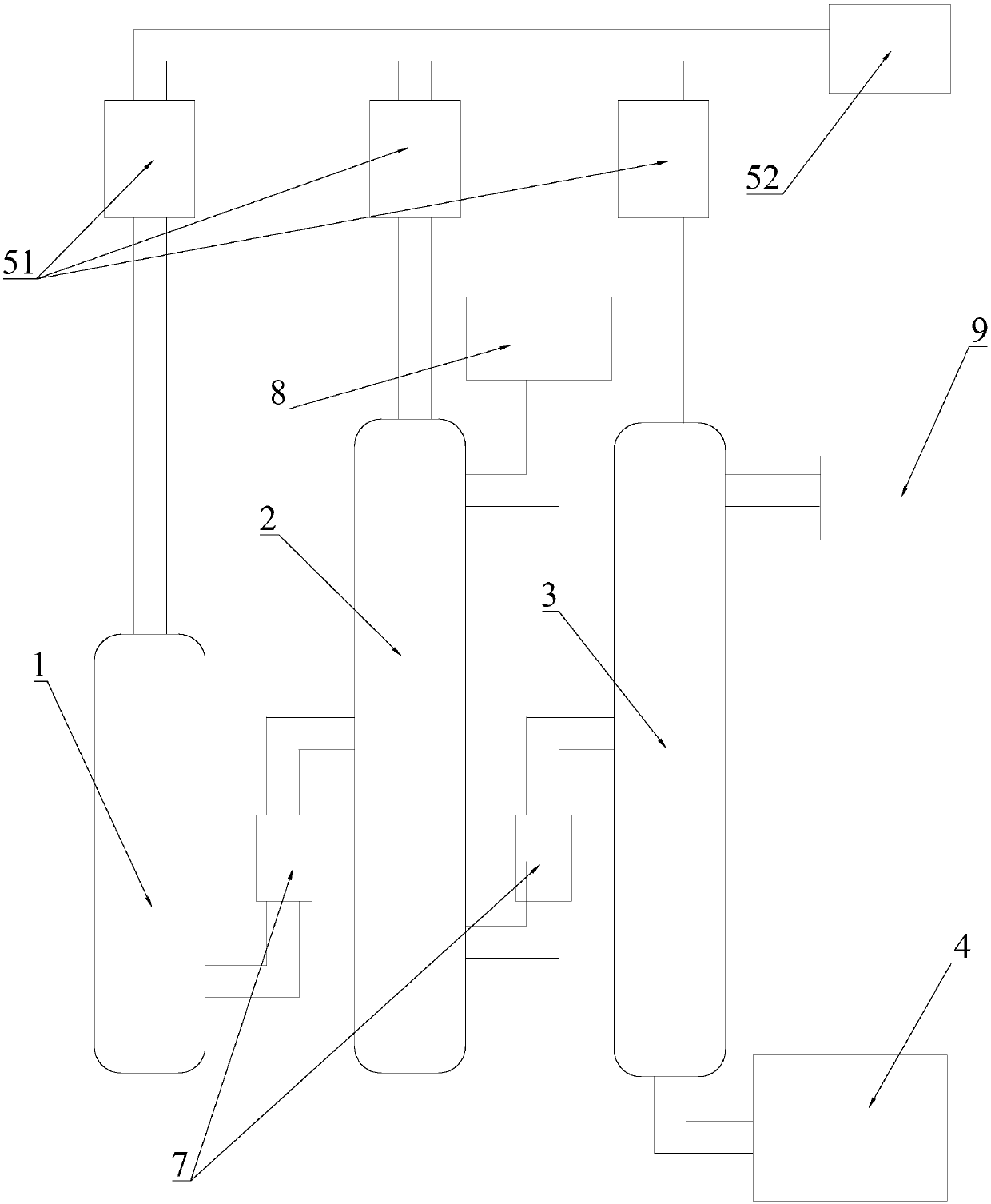

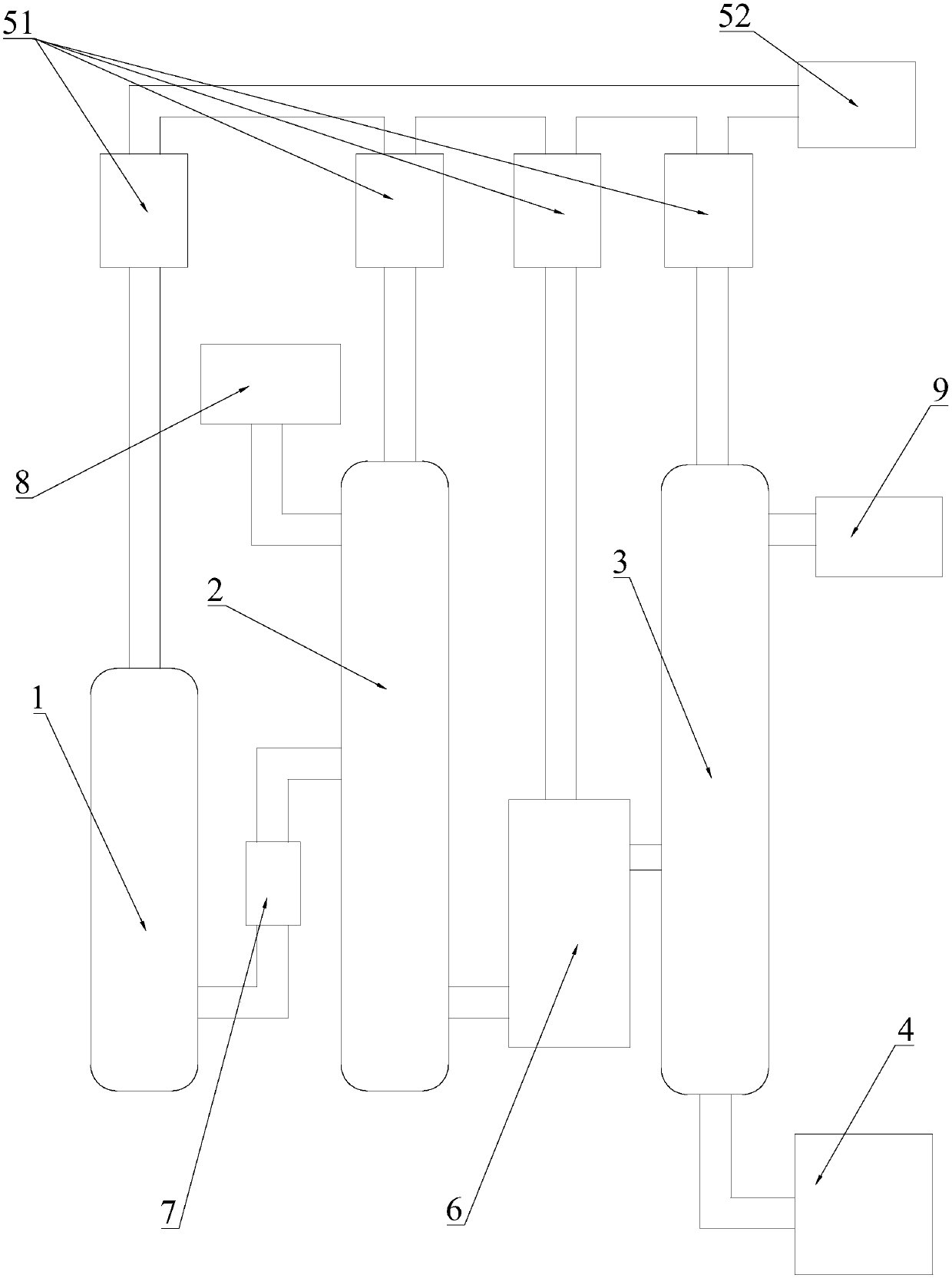

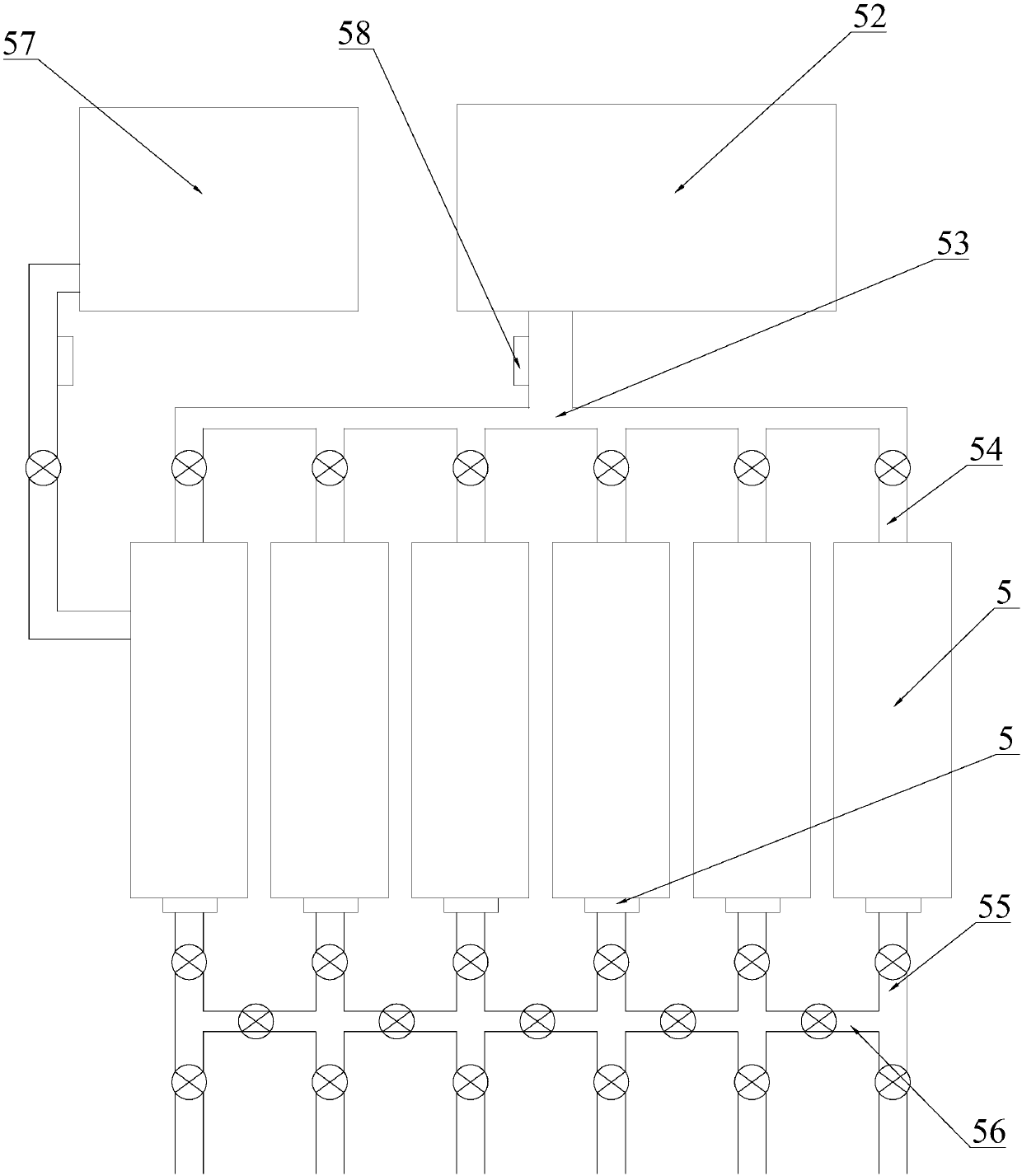

[0025] see figure 1 , figure 2 , image 3 Shown, the technical solution of the present invention is to provide a kind of following structure and comprise α-pinene vacuum separation tower 2, β-pinene vacuum separation tower 3 and raffinate tank 4, also comprise vacuumizing device 5, so Described vacuum pump 5 vacuum pumps 52 and some vacuum tanks 51, described α-pinene vacuum separation tower 2, β-pinene vacuum separation tower 3 and raffinate tank 4 all communicate with a vacuum tank 51, described vacuum The bottom of the tank 51 tower is provided with a first discharge pipe, and the first discharge pipe is communicated with the 3 feed ports of the β-pinene vacuum separation tower, and the 3 bottoms of the β-pinene vacuum separation tower are provided with a second discharge pipe. The discharge pipe, the second discharge pipe is communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com