Diethylene-glycol-phthalic-anhydride-polymer microencapsulated red phosphorus flame retardant product and preparation method thereof

A phthalic anhydride polyester polyol and microencapsulation technology, which is applied in the chemical industry, can solve the problems of affecting the relevant properties of plastic products, damage to the coating layer, easy filtration, etc., and achieves strong economy, short process and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

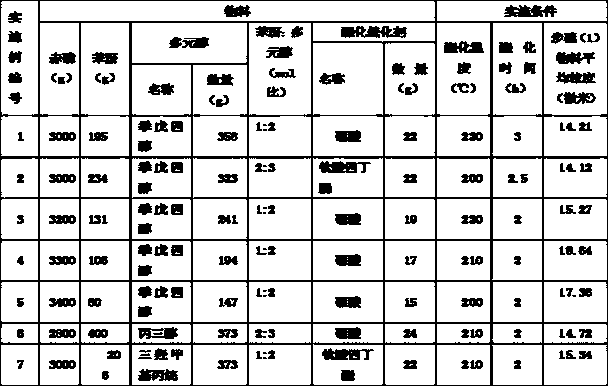

[0039] The amount of red phosphorus, phthalic anhydride, and polyols determined in Table 1 are preliminarily mixed and put into four 4L ball milling jars with stainless steel balls in advance and replaced with nitrogen gas, and then vibrate and replace the upper space with nitrogen gas, then cover the ball milling jars. , put into a vertical planetary mill and pulverize until the average particle size is less than 20 microns, after pulverization, take out the ball mill tank and separate the balls to obtain a mixture. Transfer the above-mentioned mixture to the kneader, add the catalyst of the determined amount in Table 1, and start the heating function under stirring conditions, so that the temperature of the material rises to the value of the esterification temperature in Table 1 and maintain the esterification time specified in Table 1 The numerical value, stop heating, cool down, obtain product. The relevant indicators of the product are tested according to the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com