All-steel radial tire combined rubber compound for improving shoulder separation and tread separation

A radial tire and shoulder hollow technology, applied in the field of all-steel radial tire compound production, can solve the problem of limited improvement of compound anti-aging performance, anti-vulcanization reversion performance, and anti-fatigue performance, low constant elongation modulus, and low improvement effect, etc. The problem is to improve the tire's ability to resist long-term high-load running, high modulus of constant elongation, and improve heat aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

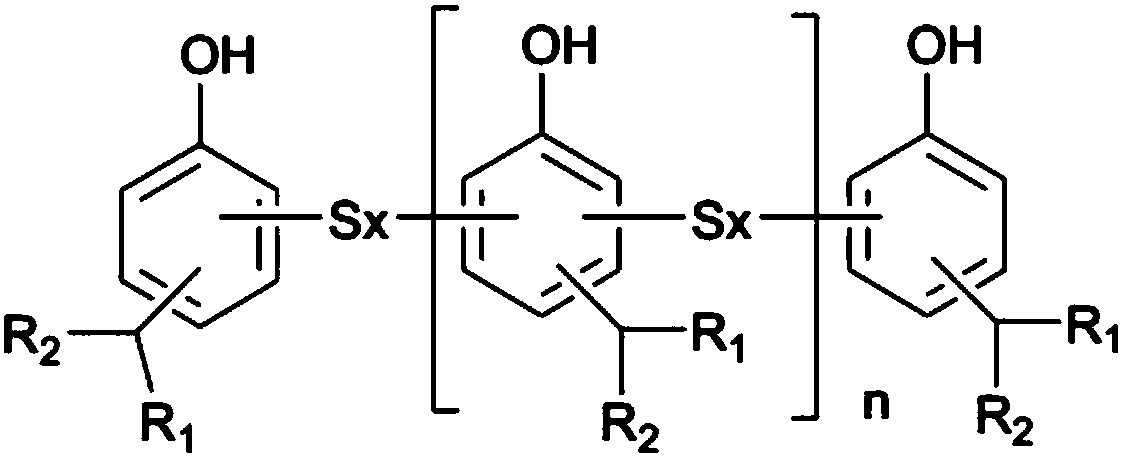

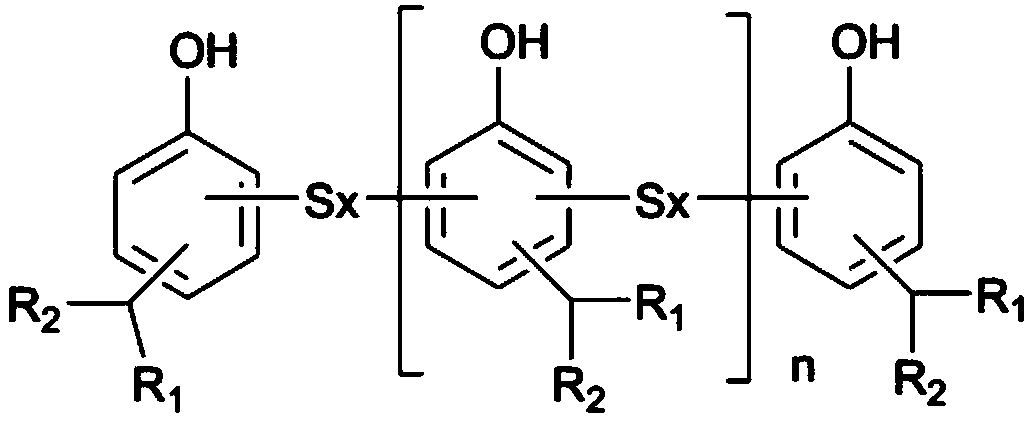

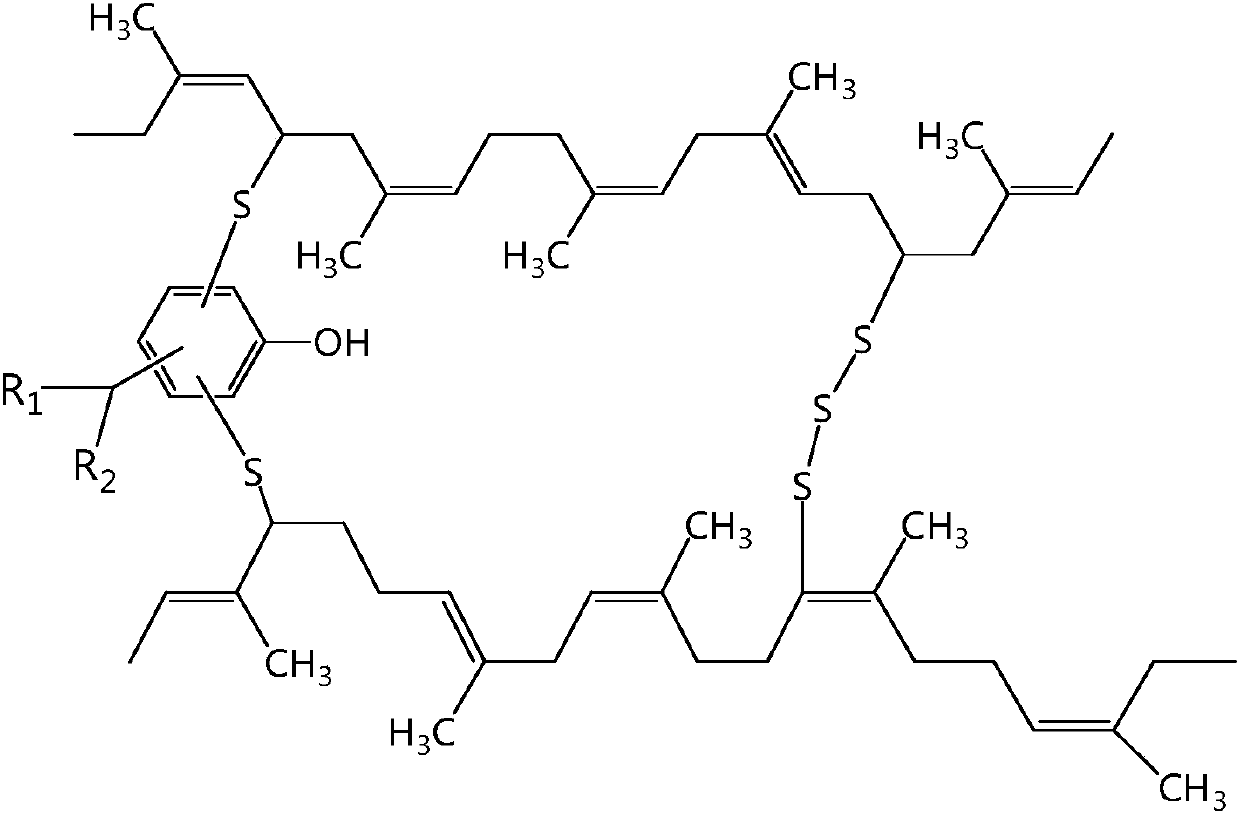

Image

Examples

Embodiment Construction

[0038] Instructions for use of raw materials:

[0039] The natural rubber referred to in the present invention includes smoked sheet rubber 1#, 3#, standard rubber 10#, 20# produced in different countries, national standard SCR5#, SCR10#, and composite rubber with a natural rubber content of more than 95%;

[0040] The invention discloses a combined rubber material for all-steel radial tires with improved shoulder and crown spaces, and the combined rubber material is used to prepare shoulder pad rubber and base rubber respectively.

[0041] Each component of the shoulder pad rubber raw material is composed as follows according to parts by weight:

[0042] 80.0-95.0 parts of natural rubber, 5.0-20.0 parts of butadiene rubber, 30.0-45.0 parts of carbon black, 8.0-15.0 parts of white carbon black, 3.0-6.0 parts of zinc oxide, 1.0-3.0 parts of active agent stearic acid, carbon black dispersion 1.0-2.0 parts of anti-aging agent, 0.5-1.5 parts of anti-aging agent RD, 1.5-2.5 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com