Fluorosilicone resin/composite modified nano-material hybrid super-amphiphobic coating and preparation technology thereof

A technology of composite modification and fluorosilicone resin, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of coating film-forming property decline, achieve improved dispersion, improve hydrophilic characteristics, and improve the formation of microscopic rough structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

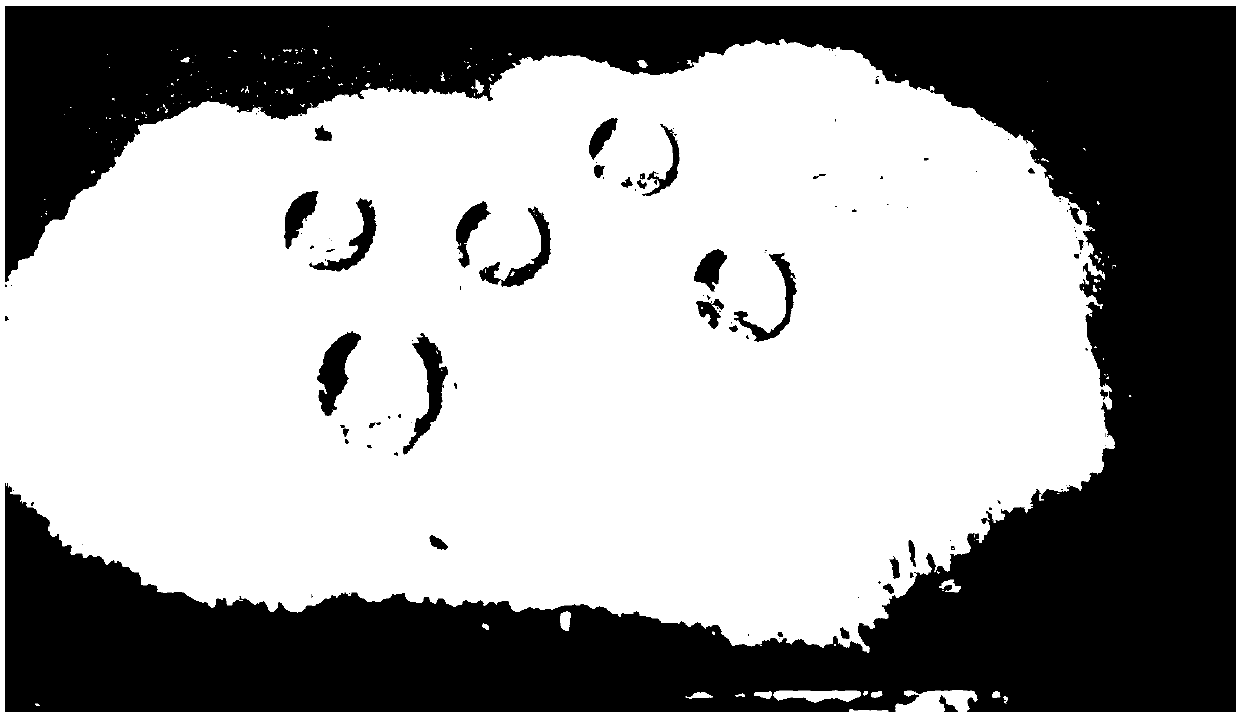

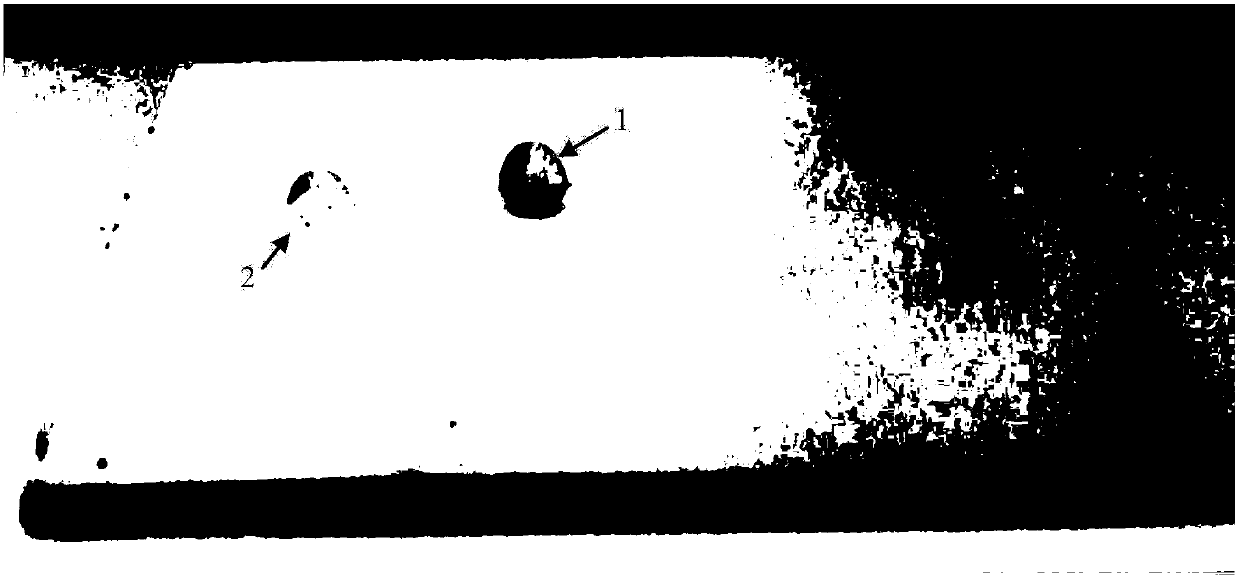

[0066] A wear-resistant fluorosilicone resin / composite modified nano-SiO 2 -TiO 2 Hybrid super-amphiphobic coating, including the weight percentage of the following components: 30% fluorosilicone resin, 39% dispersion solvent, composite modified nano-SiO 2 -TiO 2 Particles 30%, coupling agent 0.7%, defoamer 0.3%.

[0067] In this embodiment, wear-resistant fluorosilicone resin / composite modified nano-SiO 2 -TiO 2 The preparation process of hybrid super amphiphobic coating comprises the following steps:

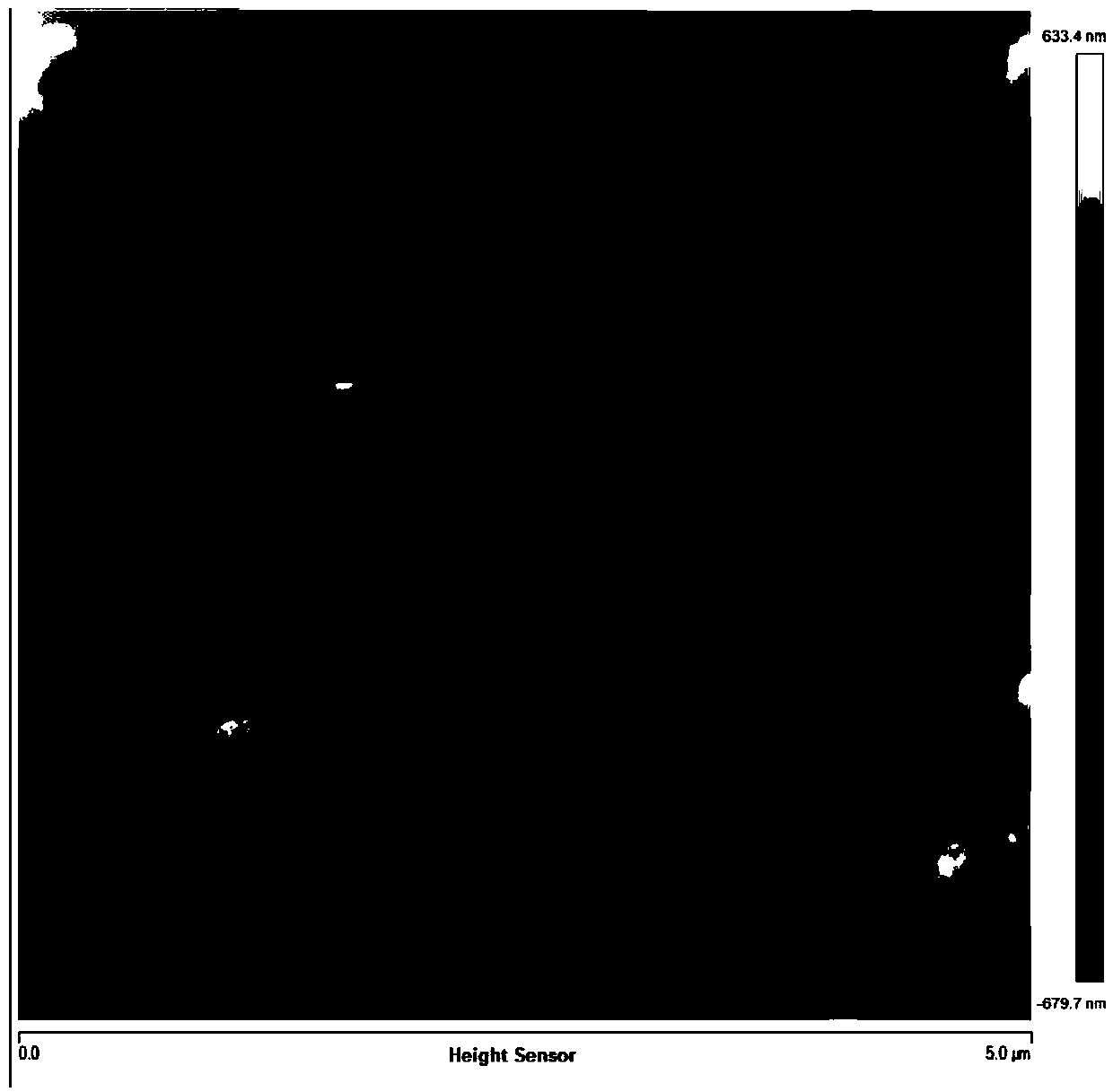

[0068] 1. Nano SiO 2 with nano TiO 2 Composite modification treatment to obtain composite modified nano-SiO 2 -TiO 2 .

[0069] (1) Blended ball milled nano-SiO 2 -TiO 2 Preparation of powder: weigh a certain amount of nano-scale SiO 2 , Nanoscale TiO 2 , placed in a mixer and mixed evenly, and then placed in a planetary ball mill for ball milling to obtain a blended ball milled nano-SiO 2 -TiO 2 powder. nano-SiO 2 The particle size is 20~30nm, nano TiO 2 Par...

Embodiment 2

[0081] A wear-resistant fluorosilicone resin / composite modified nano-SiO 2 -TiO 2 Hybrid super-amphiphobic coating, including the weight percentage of the following components: 30% fluorosilicone resin, 49% dispersion solvent, composite modified nano-SiO 2 -TiO 2 Particles 20%, coupling agent 0.7%, defoamer 0.3%. In this embodiment, wear-resistant fluorosilicone resin / composite modified nano-SiO 2 -TiO 2 The preparation process of the hybrid super-amphiphobic coating is the same as in Example 1.

Embodiment 3

[0083] A wear-resistant fluorosilicone resin / composite modified nano-SiO 2 -TiO 2 Hybrid super-amphiphobic coating, including the weight percentage of the following components: 30% fluorosilicone resin, 50% dispersion solvent, composite modified nano-SiO 2 -TiO 2 Particles 19%, coupling agent 0.7%, defoamer 0.3%. In this embodiment, wear-resistant fluorosilicone resin / composite modified nano-SiO 2 -TiO 2 Composite modified nano-SiO in the preparation process of hybrid superamphiphobic coating 2 -TiO 2 The coupling agent used is tridecafluorooctyltriethoxysilane, and other processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com