Preparation method for sulfamic acid type impact nickel

The technology of sulfamic acid type and sulfamic acid nickel is applied in the field of preparation of sulfamic acid type impact nickel, which can solve problems such as corrosion of electroplating equipment, and achieve the effects of reducing the degree of corrosion, reducing the content of chloride ions, and improving the effect of electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

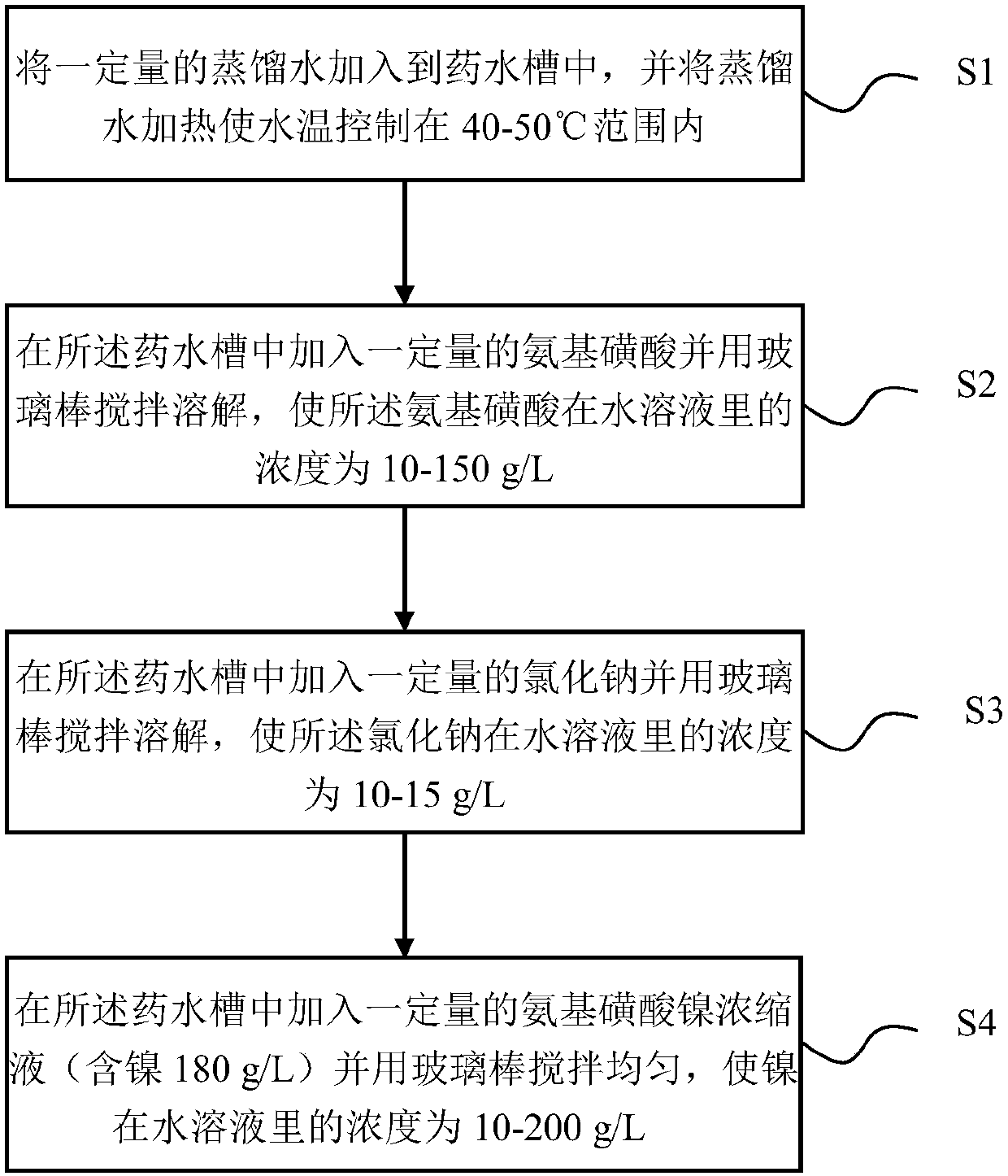

[0013] figure 1 It is a flowchart of the preparation method of the sulfamic acid type impact nickel according to the embodiment of the present invention. The preparation method of the sulfamic acid type impact nickel provided by the invention comprises the following steps:

[0014] In step S1, a certain amount of distilled water is added into the liquid medicine tank, and the distilled water is heated to control the water temperature within the range of 40-50°C.

[0015] In step S2, a certain amount of sulfamic acid is added into the liquid medicine tank and stirred and dissolved with a glass rod, so that the concentration of the sulfamic acid in the aqueous solution is 10-150 g / L.

[0016] In step S3, a certain amount of sodium chloride is added into the liquid medicine tank and stirred and dissolved with a glass rod, so that the concentration of the sodium chloride in the aqueous solution is 10-15 g / L.

[0017] In step S4, a certain amount of nickel sulfamate concentrate (...

no. 1 example

[0019] The first embodiment: first, a certain amount of distilled water is added into the liquid medicine tank, and the distilled water is heated so that the water temperature is controlled at 45°C; secondly, a certain amount of sulfamic acid is added into the liquid medicine tank and stirred and dissolved with a glass rod, Make the concentration of described sulfamic acid in the aqueous solution be 40g / L; Then, add a certain amount of sodium chloride and stir and dissolve with glass rod in the described liquid medicine tank, make the concentration of described sodium-chlor in the aqueous solution be 10g / L; At last, add a certain amount of nickel sulfamate concentrate (nickel-containing 180g / L) in the liquid medicine tank and stir evenly with a glass rod, so that the concentration of nickel in the aqueous solution is 10g / L to 200g / L, The nickel concentration gradient was 10g / L, and 20 groups of sulfamic acid impact nickel solutions with different nickel contents were prepared....

no. 2 example

[0020] The second embodiment: first, a certain amount of distilled water is added into the liquid medicine tank, and the distilled water is heated so that the water temperature is controlled at 45°C; secondly, a certain amount of sulfamic acid is added into the liquid medicine tank and stirred and dissolved with a glass rod, Make the concentration of the sulfamic acid in the aqueous solution be 10g / L to 150g / L, the concentration gradient of the sulfamic acid is 10g / L, make 15 groups of comparative tests; then, add a certain amount of chlorinated Sodium is also stirred and dissolved with a glass rod, so that the concentration of the sodium chloride in the aqueous solution is 10g / L; at last, a certain amount of nickel sulfamate concentrate (containing nickel 180g / L) is added in the liquid medicine tank and mixed with glass Stir the rod evenly, so that the concentration of nickel in the aqueous solution is 40g / L, and prepare 15 groups of sulfamic acid impact nickel solutions with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com