Inflatable cable and preparation method for the same

An inflatable, cable technology, used in cable/conductor manufacturing, insulated cables, cables, etc., can solve problems such as poor burst resistance, poor softness, physical and mechanical properties, tensile strength and elongation. The effect of good integrity, good softness and anti-cracking performance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

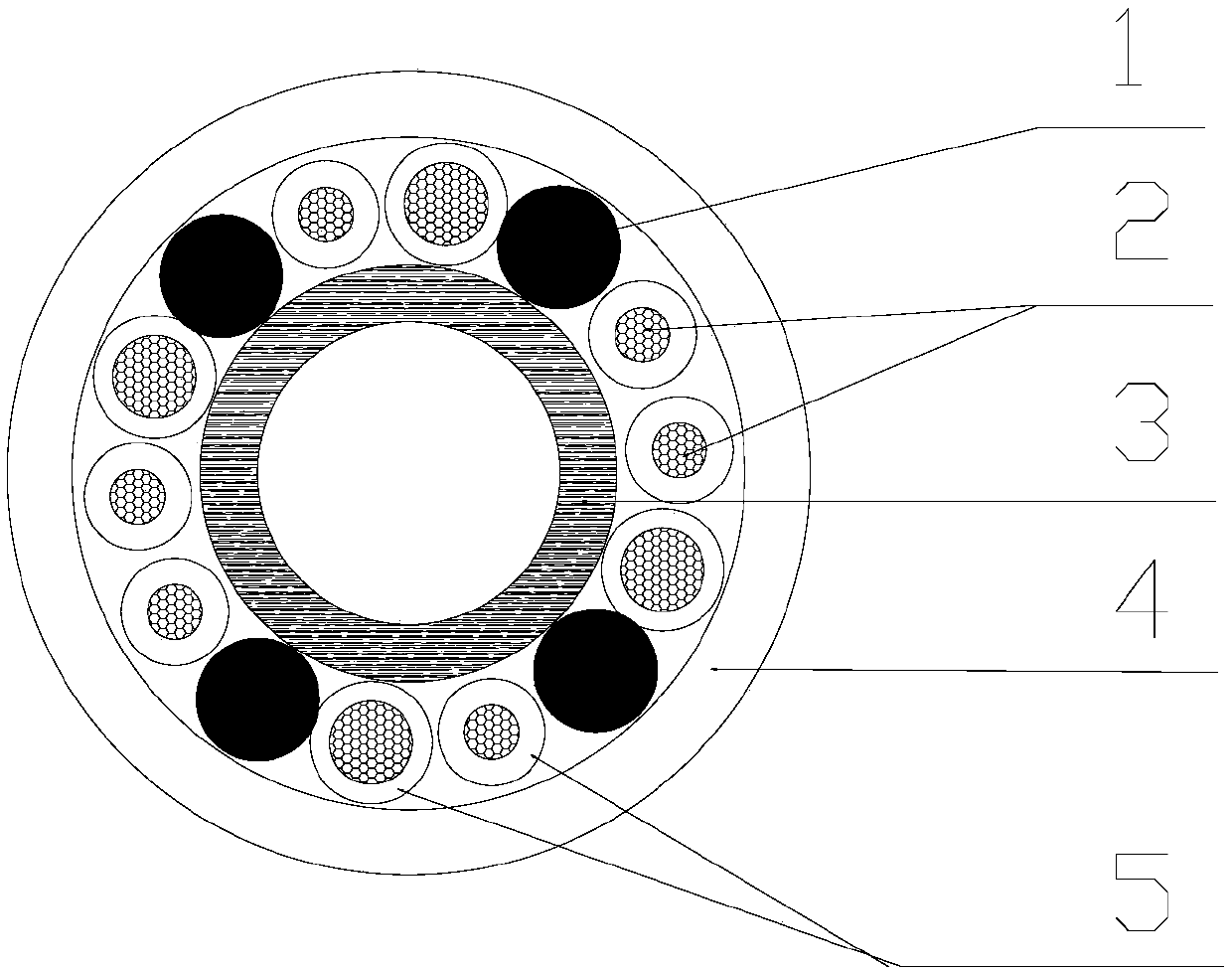

[0032] An inflatable cable, including an inflatable tube 3, a control wire core, a filling rod and a sheath layer 4; the inflatable tube 3 is located at the center, and an insulated core is arranged on the outside of the inflatable tube 3, and the control core is insulated by a conductor 2 and extruded Layer 5, the conductor 2 is a copper wire twisted structure, the outside of the control core and the outer diameter and roundness of the cable are wrapped with tissue paper, and the outer sheath layer 4 is extruded. The outer side is extruded with a sheath layer 4 .

[0033] The insulating layer is made of cross-linked polyethylene insulating material with a temperature resistance grade of -40°C to 105°C, and the sheath layer is made of polyolefin elastomer material.

Embodiment 2

[0035] A method for preparing an inflatable cable, the preparation process comprising the following steps:

[0036] 1. Conductor stranding: the conductor is made of soft copper conductor, and the stranding pitch ratio is 11-14;

[0037] 2. Extruded insulating layer: the insulating layer is produced by extruding irradiated cross-linked polyethylene material with a temperature grade of -40°C to 105°C; the thickness of the insulating layer of the control wire core is 0.4mm-0.6mm;

[0038] 3. Cable forming: use a cable forming machine to form cables, so that the inflatable tube is located in the middle, and an elastomer filling rod is arranged between the control wire cores, which are arranged and covered on the outside of the inflatable tube to ensure the roundness of the cable. The diameter ratio is 14-16 times;

[0039] 4. Wrapping isolation layer: The isolation layer is formed by overlapping wrapping with tissue paper, and the wrapping coverage rate is greater than 30%;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com